When it comes to maintaining your vehicle’s air conditioning system, one critical aspect is ensuring that the AC coolant is at the appropriate level. The coolant, often referred to as refrigerant, plays a vital role in absorbing heat from the interior of the car and expelling it outside, thereby keeping the cabin cool and comfortable.

Inadequate coolant levels can lead to inefficiencies, higher energy consumption, and even complete system failure. This guide will walk you through how to check ac coolant, ensuring optimal performance and longevity for your vehicle’s air conditioning system.

Understanding AC Coolant

AC coolant, commonly known as refrigerant, is a specially formulated substance that facilitates heat exchange in your vehicle’s air conditioning system. It exists in both gas and liquid states, cycling through the system to absorb heat from the cabin air and release it outside. The most prevalent types of refrigerant used in modern vehicles are R-134a and R-1234yf, each with distinct properties and environmental impacts.

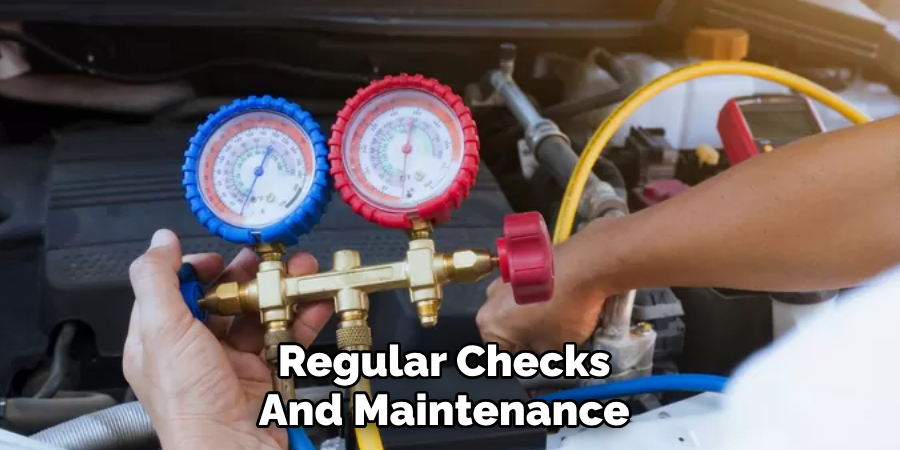

Understanding the function and types of AC coolant is crucial not only for efficient cooling but also for environmental considerations, as certain refrigerants may contribute to ozone depletion if not handled properly. Regular checks and maintenance of the AC coolant levels are essential to ensure the system operates efficiently and to extend its lifespan.

10 Methods How to Check Ac Coolant

1. Understand the Signs of Low Refrigerant

Before diving into technical methods, it’s essential to recognize the symptoms of low refrigerant levels. Common signs include reduced cooling efficiency, warm air blowing from the vents, and ice forming on the evaporator coils.

You may also notice a hissing or bubbling sound coming from the refrigerant lines. By being aware of these signs, you can determine whether a refrigerant check is necessary. However, these indicators are not always definitive; a proper assessment will still be needed to confirm refrigerant levels.

2. Turn Off the AC and Disconnect Power

Safety is the first priority when checking AC coolant levels. Begin by turning off the AC system from the thermostat to ensure that it is not operating while you work. Next, disconnect the power supply to the unit.

This can usually be done by switching off the breaker at the electrical panel that controls the AC system. Disconnecting the power prevents accidental electric shocks and ensures that the system is not running while you handle refrigerant lines or gauges.

3. Locate the Service Ports

The refrigerant service ports are where you will connect your gauges to check the coolant levels. These ports are typically found on the refrigerant lines running between the outdoor condenser unit and the indoor evaporator coil.

The low-pressure service port is generally located on the larger of the two lines, while the high-pressure port is on the smaller line. Refer to the system’s manual or look for labels near the ports to ensure you are connecting to the correct service port.

4. Use a Manifold Gauge Set

A manifold gauge set is an essential tool for checking refrigerant levels. This set includes a set of gauges that measure both the low-pressure and high-pressure sides of the system.

Attach the blue hose from the manifold gauge set to the low-pressure service port and the red hose to the high-pressure service port. The gauges will display the pressures of each side, which can be compared to the recommended pressure levels for your specific AC model. Accurate readings are crucial for determining whether the refrigerant levels are within the acceptable range.

5. Consult the Pressure-Temperature Chart

To interpret the readings from your manifold gauge set accurately, consult a pressure-temperature chart specific to the refrigerant type used in your system (e.g., R-410A or R-22).

This chart correlates refrigerant pressure with temperature, allowing you to determine if the pressures are within the correct range for the current ambient temperature. Comparing the readings from your gauges to this chart will help you assess whether the refrigerant levels are too low or too high.

6. Inspect for Signs of Leaks

Low refrigerant levels are often the result of leaks in the system. While checking the coolant levels, inspect the refrigerant lines, connections, and coils for any visible signs of leakage, such as oil stains or frost.

You can also use a leak detection solution or UV dye to identify leaks. Apply the solution or dye to the refrigerant lines and watch for bubbling or fluorescence under UV light, indicating a leak. Addressing leaks is crucial before recharging the system with additional refrigerant.

7. Check the Refrigerant Lines for Frost or Ice

Frost or ice formation on the refrigerant lines or evaporator coils is a clear sign of refrigerant issues. When the refrigerant levels are low, the evaporator coil can freeze due to reduced heat absorption and airflow.

Examine the lines and coils for any signs of frost or ice. If present, this indicates that the system may be low on refrigerant or that there is an airflow issue. Resolving these issues may involve adding refrigerant, fixing leaks, or improving airflow.

8. Use a Refrigerant Scale for Accurate Measurement

If you need to add refrigerant to your system, a refrigerant scale can help ensure that the correct amount is added. Weigh the refrigerant canister before and after adding refrigerant to measure how much has been used.

This method helps you avoid overcharging or undercharging the system. Be sure to follow the manufacturer’s specifications for the exact amount of refrigerant required. Adding too much refrigerant can lead to high pressures and potential damage, while too little can result in insufficient cooling.

9. Observe the System’s Performance

After checking and potentially adjusting the refrigerant levels, observe the system’s performance. Turn the AC system back on and monitor its operation for any changes. Pay attention to the air temperature coming from the vents, the system’s ability to cool effectively, and any unusual noises.

A well-functioning system should provide consistent cooling without excessive noise or ice formation. If issues persist despite proper refrigerant levels, there may be other underlying problems that need professional attention.

10. Consult a Professional for Persistent Issues

If you are uncomfortable performing these checks or if the system continues to show signs of refrigerant issues despite your efforts, it’s advisable to consult a licensed HVAC technician. A professional can perform a thorough diagnostic to identify and resolve problems that may not be apparent through basic checks.

They can also handle refrigerant charging safely and ensure that the system operates efficiently. Regular professional maintenance is essential for keeping your AC system in top condition and preventing future issues.

Things to Consider When Checking AC Refrigerant Levels

- Know Your Refrigerant Type

Different AC systems use specific types of refrigerants, such as R-410A or R-22. Knowing which refrigerant is used in your system is crucial not only for accurate measurements but also for compliance with environmental regulations during servicing.

- Safety Precautions

Always wear appropriate safety gear, including gloves and goggles, when handling refrigerants. These substances can be harmful if they come into contact with skin or if inhaled, so prioritising personal safety is essential.

- Environmental Impact

Be mindful of the environmental regulations regarding refrigerant handling and disposal. Improperly releasing refrigerant into the atmosphere contributes to ozone depletion and global warming, so use recovery systems when necessary.

- System-Specific Guidelines

Consult your AC system’s manufacturer manual for specific guidelines related to refrigerant levels and system operation. These documents provide critical information on servicing procedures tailored to your unit.

Common Mistakes to Avoid

- Neglecting Regular Maintenance

One of the most significant mistakes is failing to schedule regular maintenance checks for your AC system. Without periodic inspections, small issues can escalate into costly repairs. Routine maintenance helps identify refrigerant problems early and ensures optimal system performance.

- Overlooking Manufacturer Guidelines

Ignoring the specific guidelines provided by your system’s manufacturer can lead to improper servicing. Each AC unit has unique requirements regarding refrigerant type and the amount needed. Always refer to these guidelines before making any adjustments.

- Failing to Use the Right Tools

Using incorrect or substandard tools can compromise your ability to accurately assess refrigerant levels. Invest in quality equipment, such as a reliable manifold gauge set and refrigerant scale, to ensure precise measurements and prevent potential damage to the system.

- Adding Refrigerant Without Identifying Underlying Issues

Simply adding refrigerant without diagnosing the root cause of low levels, such as leaks or airflow issues, can be a costly mistake. This approach not only creates further problems but may also result in overcharging, leading to additional system damage.

Conclusion

Maintaining the proper refrigerant levels in your AC system is critical for its efficiency and longevity. Regular checks and immediate attention to any signs of refrigerant issues can prevent more significant problems and costly repairs down the line.

By understanding the basics of refrigerant types, adhering to safety precautions, and recognizing common mistakes, you can ensure your cooling system operates optimally. Thanks for reading, and we hope this has given you some inspiration on how to check ac coolant!