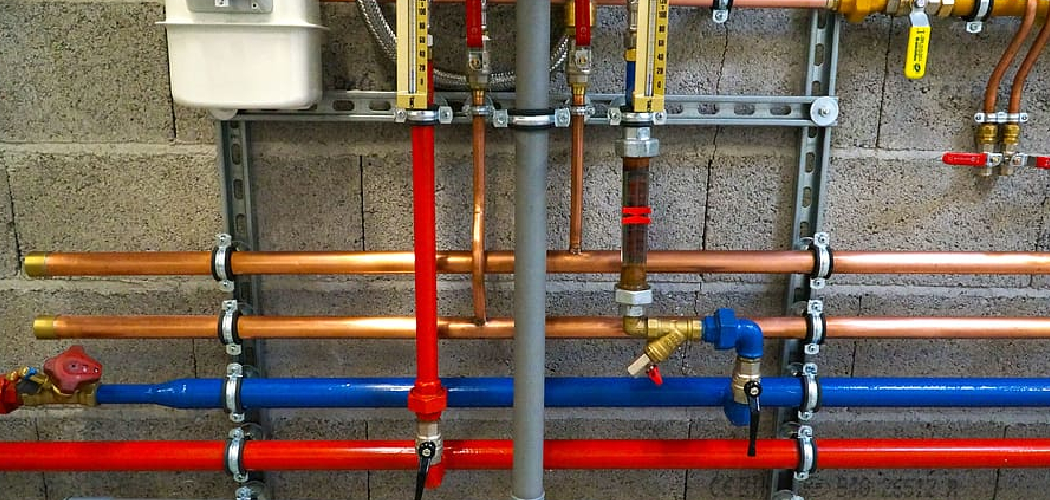

Flexible PVC pipe is a versatile and durable material commonly used in plumbing, irrigation, and pool systems. Its flexibility allows for easy installation around corners and obstacles, making it an ideal choice for complex layouts. Properly

connecting flexible PVC pipe ensures a secure and leak-free system, and with the right tools and techniques, this process can be both straightforward and efficient. This guide will walk you through the steps of how to connect flexible pvc pipe for your project.

Advantages of Flexible PVC Pipes

Flexible PVC pipes offer numerous advantages that make them a popular choice for various applications. One of their primary benefits is their adaptability; their flexibility allows them to bend and curve around obstacles, reducing the need for additional fittings and simplifying complex installations.

They are also highly durable and resistant to cracking, even under pressure or when exposed to temperature fluctuations. Additionally, flexible PVC pipes are corrosion-resistant, making them ideal for use in systems with water exposure or chemical flow. Their lightweight nature makes them easy to transport and handle, while their long lifespan ensures cost-effectiveness over time. These qualities make flexible PVC pipes a reliable and efficient solution for both residential and commercial projects.

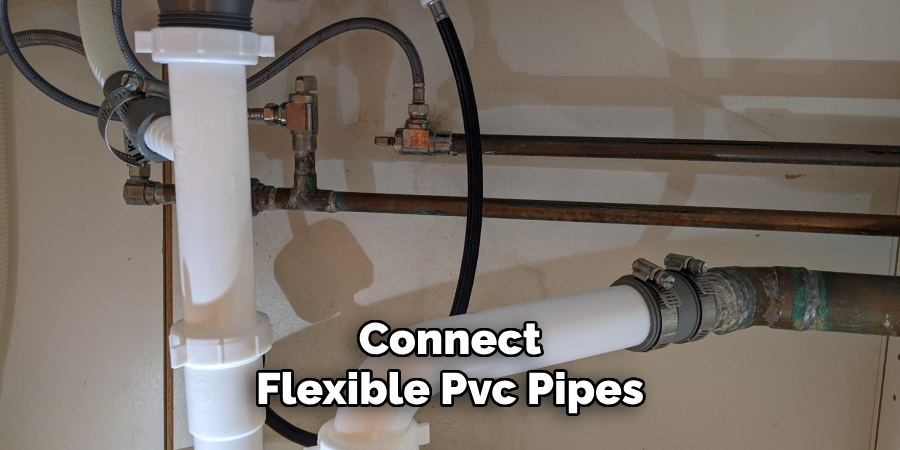

Importance of Proper Connection Techniques

Ensuring proper connection techniques when working with flexible PVC pipes is crucial for the longevity and functionality of your system. Incorrect connections can lead to leaks, reduced water pressure, or even system failures, which can be costly and time-consuming to repair.

Proper techniques ensure a tight and secure seal, preventing potential water damage or waste. Additionally, a well-connected system minimizes the risk of contaminants entering the flow, maintaining the integrity of the water or substance being transported. By taking the time to properly measure, prepare, and join the pipes, you can create a reliable system that performs efficiently and withstands the test of time. This attention to detail is especially important in systems under pressure or those exposed to shifting environmental conditions.

Tools and Materials Needed

To successfully connect flexible PVC pipes, you will need the following tools and materials:

- Flexible PVC Pipe: Ensure you have the correct diameter and length for your project.

- PVC Fittings: Elbows, tees, or couplings as needed for your connections.

- PVC Primer and Cement: For securing strong, watertight joints.

- Pipe Putter or Hacksaw: To cut the pipes to the desired length.

- Measuring Tape: For accurate measurements to ensure proper fitting.

- Deburring Tool or Sandpaper: To smooth the edges of cut pipes for a clean connection.

- Marker or Pencil: To mark the pipes for cutting and alignment.

- Clean Cloth: For wiping debris or dirt from the ends of the pipes before assembling.

Having these tools and materials readily available will help ensure a smooth and efficient installation process.

10 Methods How to Connect Flexible Pvc Pipe

1. Using PVC Cement for Permanent Connections

One of the most common methods to connect flexible PVC pipe is by using PVC cement. Begin by cutting the pipe to the desired length using a PVC cutter or a fine-toothed saw. Ensure the cut is clean and square to promote a tight seal. Apply PVC primer to the inside of the fitting and the outside of the pipe end. Follow up with PVC cement, spreading it evenly over the primed areas. Quickly insert the pipe into the fitting, giving it a quarter-turn twist to distribute the cement evenly. Hold the connection in place for at least 30 seconds to allow the cement to set. Allow the joint to cure for 24 hours before subjecting it to pressure.

2. Using Barbed Fittings and Hose Clamps

Barbed fittings are specifically designed for flexible PVC pipes. To use this method, slide a hose clamp onto the pipe before inserting the barbed fitting into the pipe end. Push the fitting in firmly, ensuring it seats completely. Once the fitting is in place, position the hose clamp over the barbed section and tighten it using a screwdriver or a socket wrench. This connection is reliable and can be loosened for adjustments if necessary.

3. Installing Compression Fittings

Compression fittings are a great option for connecting flexible PVC pipes without using glue. These fittings typically consist of a nut, a ferrule, and a body. Slide the nut and ferrule onto the pipe, then insert the pipe into the fitting body. Tighten the nut over the body, compressing the ferrule to create a watertight seal. Compression fittings are especially useful for applications where disassembly might be required in the future.

4. Heat-Sealing for Tight Joints

Flexible PVC pipe can be softened with heat to ensure a tight fit. Use a heat gun to gently warm the pipe end, being careful not to overheat or burn the material. Once the pipe is pliable, insert it into the fitting. Allow the pipe to cool naturally, which will cause it to contract and create a snug connection. This method is particularly useful for fittings without threads or barbs but may require additional clamping for long-term security.

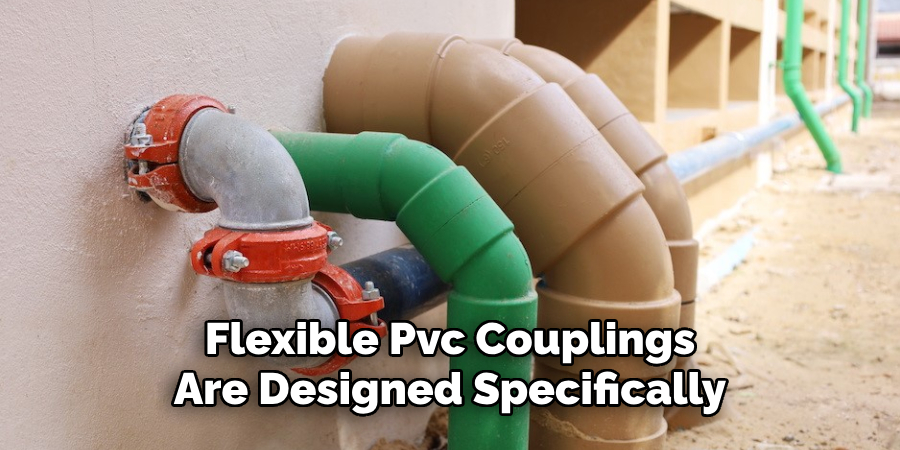

5. Using Flexible PVC Couplings

Flexible PVC couplings are designed specifically for joining sections of flexible PVC pipe. These couplings typically feature a rubber body and stainless steel clamps. To use, slide the coupling onto the ends of the two pipes you wish to connect.

Tighten the clamps using a screwdriver or wrench to secure the connection. Flexible couplings are ideal for quick repairs and can accommodate slight misalignments between pipes.

6. Threaded Connections with Adapters

For applications requiring threaded connections, use threaded PVC adapters. Begin by applying Teflon tape or pipe thread sealant to the male threads of the adapter. Screw the adapter into the threaded fitting by hand, then tighten it further with a wrench. Insert the flexible PVC pipe into the smooth end of the adapter, securing it with PVC cement or a hose clamp, depending on the adapter type. Threaded connections are versatile and allow for easy disassembly when needed.

7. Creating a Flange Connection

Flange connections are ideal for larger diameter flexible PVC pipes. To create a flange connection, attach a PVC flange to the end of each pipe section using PVC cement. Align the flanges and secure them together using bolts and a gasket to ensure a leak-free seal. This method is commonly used in industrial applications and allows for easy maintenance and pipe replacement.

8. Using Solvent Welds for Complex Systems

Solvent welding is another effective technique for connecting flexible PVC pipe. Apply a solvent welding adhesive to the pipe and fitting, then quickly insert the pipe into the fitting. The solvent temporarily softens the PVC, allowing the materials to fuse together as they harden. This method creates a permanent, seamless joint that is resistant to leaks. Ensure you work quickly and accurately, as the adhesive sets rapidly.

9. Utilizing Push-Fit Fittings

Push-fit fittings are an excellent option for DIY projects or systems requiring frequent adjustments. These fittings use

internal O-rings to create a watertight seal. Simply push the flexible PVC pipe into the fitting until it clicks into place. No tools or adhesives are required, making this method quick and user-friendly. Push-fit fittings are reusable, allowing for easy disassembly and reconfiguration.

10. Securing Connections with Clamps and Straps

In some cases, additional support is necessary to maintain a secure connection. After using any of the above methods, secure the pipe with clamps or straps to prevent movement and stress on the joints. Position the clamps or straps at regular intervals along the pipe and tighten them snugly. This added support is particularly important for systems exposed to vibrations or external forces.

Maintenance and Upkeep

Proper maintenance and upkeep of flexible PVC pipe systems are crucial for ensuring long-term performance and durability. Regular inspections should be conducted to check for leaks, cracks, or signs of wear, especially at connection points and fittings. Clean the pipes periodically to prevent blockages or buildup that could affect water flow. Use a soft cloth or appropriate pipe cleaner to remove debris without causing damage to the pipe surface.

Additionally, avoid exposing flexible PVC pipes to prolonged direct sunlight, as UV rays can degrade the material over time. If outdoor installation is necessary, consider using UV-resistant coatings or burying the pipes below ground. For systems exposed to freezing temperatures, ensure proper insulation to prevent the pipes from cracking due to freezing water. Address minor issues promptly to prevent them from escalating into costly repairs. By following these upkeep practices, you can significantly extend the lifespan and efficiency of your flexible PVC pipe system.

Conclusion

Connecting flexible PVC pipe requires attention to detail and the right tools for the job. Each of these ten methods offers unique advantages, allowing you to choose the best option for your specific application. Whether you’re creating a permanent installation with PVC cement or opting for a more flexible approach with push-fit fittings, proper technique is key to ensuring a reliable and leak-free system. Thanks for reading, and we hope this has given you some inspiration on how to connect flexible pvc pipe!