Are you considering using Sharkbite fittings for your next plumbing project? If so, you may wonder how to properly connect them to PEX pipes.

Connecting SharkBite fittings to PEX tubing is a quick and straightforward process that eliminates the need for traditional soldering or specialized tools. SharkBite fittings are a popular choice for DIY enthusiasts and professionals due to their reliability, ease of use, and versatility. Whether you’re working on a plumbing repair, an upgrade, or a new installation, understanding how to connect these fittings to PEX properly will help ensure a secure and leak-free connection.

This guide on how to connect sharkbite to pex will walk you through the essential steps to achieve a successful connection with minimal hassle. Let’s dive in!

What Are the Benefits of Using SharkBite Fittings?

Before we dive into the steps on connecting SharkBite fittings to PEX, let’s first look at why these fittings are an excellent choice for your plumbing needs. Here are some of the benefits of using SharkBite fittings:

- No Specialty Tools Required: One of the most significant advantages of using SharkBite fittings is that you don’t need any specialized tools or torches. All you need is a simple pipe cutter and a deburring tool.

- Easy to Install: With traditional plumbing methods, connecting pipes can be time-consuming and challenging. However, with SharkBite fittings, all it takes is a push-to-connect method, making installation quick and easy.

- Versatility: SharkBite fittings can be used with various pipes, including PEX, copper, CPVC, and PE-RT. This versatility makes it a go-to choice for many plumbers.

- Leak-Free Connections: Thanks to the unique design of SharkBite fittings, they always create leak-free connections. This means less worry about costly leaks in the future.

These are just a few reasons why SharkBite fittings have become so popular in the plumbing industry.

What Will You Need?

Before starting the process of connecting SharkBite fittings to PEX, make sure you have all the necessary tools and materials. Here’s a list of what you’ll need:

- SharkBite Fittings: Of course, you’ll need the SharkBite fittings themselves. Make sure to choose the appropriate type and size for your project.

- PEX Tubing: You’ll also need PEX tubing to connect with the fittings. Make sure to measure and cut it to the desired length before beginning.

- Pipe Cutter: A pipe cutter is necessary to cut through the PEX tubing cleanly and accurately.

- Deburring Tool: After cutting through the PEX tubing, use a deburring tool to smooth out the edges and remove any burrs.

- Marker or Sharpie: A marker or Sharpie will help mark the insertion depth on the PEX tubing.

Once you have all the necessary tools and materials, you can connect SharkBite fittings to PEX.

9 Easy Steps on How to Connect Sharkbite to PEX

Step 1: Cut the PEX Tubing

Carefully cut the PEX tubing to the desired length using your pipe cutter. Ensure the cut is clean and straight, as uneven cuts can cause improper connections and potential leaks. Place the tubing squarely into the pipe cutter to align correctly, and then make a single, decisive cut to avoid jagged edges. A precise cut is essential for creating a secure seal with the SharkBite fitting. Take time during this step—accuracy is key to a successful installation. Once the tubing is cut, proceed to the next step to prepare the edges of the tubing.

Step 2: Deburr and Smooth the Edges

After cutting the PEX tubing, inspect the edges to ensure they are free of burrs or rough spots. Use a deburring tool or sandpaper to smooth out the cut edges carefully. This step is crucial to prevent damage to the O-ring inside the SharkBite fitting and to ensure a secure, watertight connection. Creating a smooth and even edge’ll reduce the risk of leaks and make the fitting process much easier. Remove any loose debris or particles left behind after deburring before moving on to the next step.

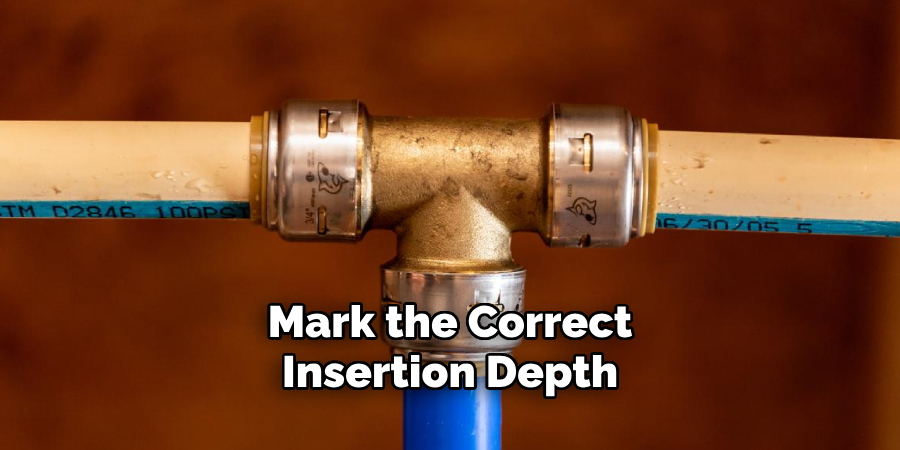

Step 3: Mark the Insertion Depth

Before inserting the PEX tubing into the SharkBite fitting, it is essential to mark the correct insertion depth. Using a SharkBite depth gauge tool, measure and mark the tubing to indicate how far it should be pushed into the fitting. This ensures the

tubing is inserted fully and properly, creating a reliable and secure connection. If the tubing is not inserted to the proper depth, the fitting may not seal correctly, which could result in leaks. Take time to double-check the marked depth for accuracy before proceeding.

Step 4: Insert the Tubing

With the correct insertion depth marked, carefully insert the PEX tubing into the SharkBite fitting. Align the tubing with the fitting and push it straight in, applying firm pressure until it reaches the marked depth. You should feel the tubing securely snap into place as the fitting’s O-ring creates a watertight seal. Ensure that the tubing is fully seated by checking that the mark on the tubing is aligned with the edge of the fitting. Proper insertion is essential for a leak-free connection. Avoid twisting or bending the tubing during this step to prevent damage to the fitting. Once inserted, inspect the connection to confirm it is secure before proceeding.

Step 5: Test the Connection

After completing the insertion, it’s crucial to test the connection to ensure it is leak-free. Slowly turn on the water supply and observe the fitting closely for any signs of leaks around the connection point. If you notice any dripping or moisture, turn off the water supply and inspect the connection for proper insertion and alignment. A secure connection should remain dry under normal water pressure. You can use the system confidently once you have confirmed that the connection is watertight. Testing is a vital step to guarantee the integrity and functionality of your plumbing installation.

Step 6: Final Inspection and Maintenance

Perform a final inspection of the system to ensure all connections are secure and functioning properly. Check for visible wear, stress, or improper alignment in the fittings and tubing. Regular maintenance is also essential to prolong the

system’s lifespan. Schedule periodic checks to verify the system remains leak-free and in optimal working condition. Proper care and attention to detail during installation and maintenance will help prevent unexpected issues and ensure reliable performance.

Step 7: Troubleshooting Common Issues

Even with careful installation and maintenance, occasional issues may arise in the plumbing system. If leaks are detected, tighten connections or replace damaged components such as washers or O-rings. Check for line blockages or clean any clogged filters for persistent low water pressure. Unusual noises in the system may indicate trapped air or loose fittings that need adjustment. Always consult the system’s manual or seek professional assistance if the problem persists. Addressing these issues will help maintain the system’s efficiency and prevent further complications.

Step 8: Keep Extra Fittings and Tools on Hand

Having spare fittings and tools readily available for unexpected repairs or replacements is always a good idea. Keeping extra SharkBite fittings, PEX tubing, pipe cutters, and deburring tools will save you time and money in the long run.

It’s also essential to stock up on any additional components necessary for your specific plumbing system, such as valves or adapters. Having these supplies on hand can help minimize downtime and prevent potential emergencies.

Step 9: Consider Hiring a Professional

While installing SharkBite fittings is relatively simple but may require technical knowledge and expertise. If you are not confident in your skills or lack experience with plumbing systems, it’s best to consult a professional plumber. They can ensure proper installation and address any potential issues that may arise. Professional assistance may also be necessary for complex or large-scale plumbing projects to guarantee optimal performance and safety. Don’t hesitate to seek help if needed—proper installation is crucial in maintaining the integrity of your plumbing system.

By following these steps and tips, you can confidently install SharkBite fittings in your plumbing system and enjoy reliable, leak-free performance for years.

5 Things You Should Avoid

- Skipping Pipe Preparation: Failing to properly clean and deburr the PEX pipe can lead to leaks or improper connections. Always ensure the pipe ends are smooth, debris-free, and cut cleanly with a pipe cutter before attaching the SharkBite fitting.

- Using Damaged PEX Pipes: Never attempt to connect SharkBite fittings to PEX pipes that are cracked, warped, or damaged. This can compromise the integrity of the connection and result in future leaks or failures.

- Forgetting to Measure Connection Depth: It’s essential to insert the PEX pipe into the SharkBite fitting to the required depth. Many fittings come with a depth gauge to help you ensure a proper seal. Neglecting this step can cause an inadequate connection.

- Twisting, Bending, or Stressing the Pipe: Avoid placing excess tension on the PEX pipe when connecting. Bending or twisting the pipe can affect the fitting’s seal and jeopardize the system’s performance over time.

- Ignoring Manufacturer Instructions: Disregarding the specific guidelines provided by SharkBite for connecting to PEX can lead to incorrect installation. Always read and follow the manufacturer’s instructions to ensure a safe and reliable connection.

Conclusion

How to connect SharkBite to PEX pipes can be a quick and reliable process when done correctly.

You can ensure a secure and lasting connection by avoiding common mistakes such as neglecting to check the pipe’s condition, failing to measure the connection depth, and mishandling the pipe through bending or twisting. Always adhere to the manufacturer’s instructions and use the proper tools for installation.

With careful preparation and attention to detail, SharkBite fittings can provide a dependable solution for your plumbing needs.