Pipe deburring tools are essential for removing burrs and sharp edges from the inside or outside of pipes, ensuring a clean and smooth finish. Proper maintenance of these tools is crucial to extend their lifespan and maintain efficiency.

This guide on how to clean pipe deburring tool will walk you through the necessary steps to clean your pipe deburring tool effectively.

Why is It Important to Clean Pipe Deburring Tools?

Like any other tool, pipe deburring tools require regular cleaning to maintain their functionality. Over time, dirt, debris, and leftover metal shavings can accumulate on the cutting edge of the tool. This buildup can affect the tool’s performance and result in a rough finish on the pipes.

Moreover, if not cleaned properly, these bits of debris can get lodged in the mechanism of the tool, causing it to jam or malfunction. Regular cleaning not only improves the tool’s performance but also prevents potential safety hazards.

Needed Materials

To clean your pipe deburring tool, you will need the following:

Clean Cloth or Rag:

To wipe away dirt and debris from the tool.

Mild Cleaning Solution:

A mild cleaning solution such as dish soap or rubbing alcohol can be used to remove stubborn buildup on the cutting edges of the tool.

Soft Bristle Brush:

A soft-bristle brush, like an old toothbrush, can help scrub away any stuck-on debris without damaging the tool’s delicate parts.

10 Steps on How to Clean Pipe Deburring Tool

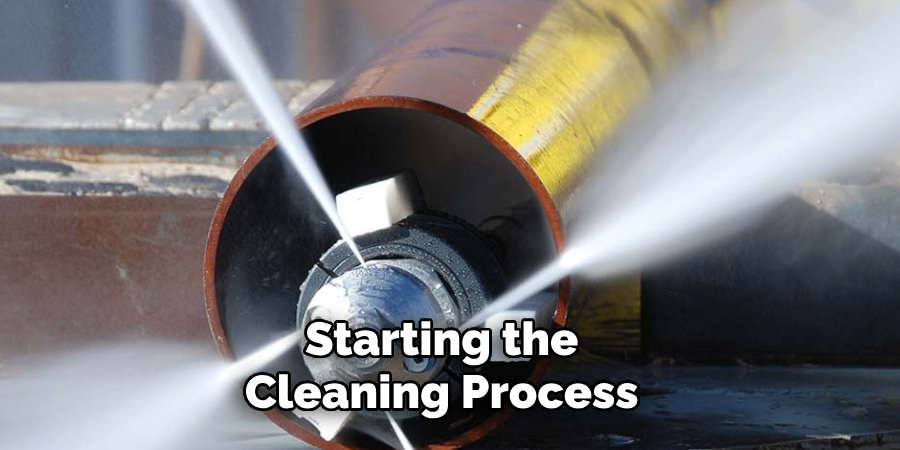

Step 1: Disconnect the Tool From Any Power Source

Before starting the cleaning process, ensure that the pipe deburring tool is disconnected from any power source, whether it is an electric or battery-powered tool. This precaution is essential to prevent any accidental activation of the tool, which could lead to injury. Safety should always be the top priority when handling tools.

You should also remove any attached accessories, such as grinding wheels, and clean them separately.

Step 2: Remove Larger Debris

Using a clean cloth or rag, gently wipe down the tool to remove any larger debris or loose dirt. Focus on areas where dust and shavings tend to accumulate, such as around the cutting edges and joints. Removing these larger particles first will make it easier to clean the smaller, more stubborn debris later. Be thorough but careful not to apply excessive force that could damage any delicate parts of the tool.

Step 3: Use a Soft Bristle Brush

Take a soft-bristle brush, such as an old toothbrush, and gently scrub the tool’s cutting edges and other intricate areas. The brush bristles help dislodge any stubborn dirt, metal shavings, or debris that may be stuck in hard-to-reach areas.

Pay extra attention to joints, grooves, and any other parts prone to buildup. Use gentle, circular motions to avoid scratching or damaging the tool’s surface. If necessary, dip the brush into a mild cleaning solution to help loosen tougher debris.

Step 4: Wipe Down the Tool

Once the stubborn debris has been loosened, take a clean cloth or rag and thoroughly wipe down the entire surface of the tool. Focus on areas that were scrubbed with the soft-bristle brush, ensuring all loosened dirt and residue are removed.

If necessary, dampen the cloth slightly with a mild cleaning solution to remove any remaining grime. Be sure to dry the tool completely using a dry portion of the cloth to prevent moisture from causing rust or corrosion.

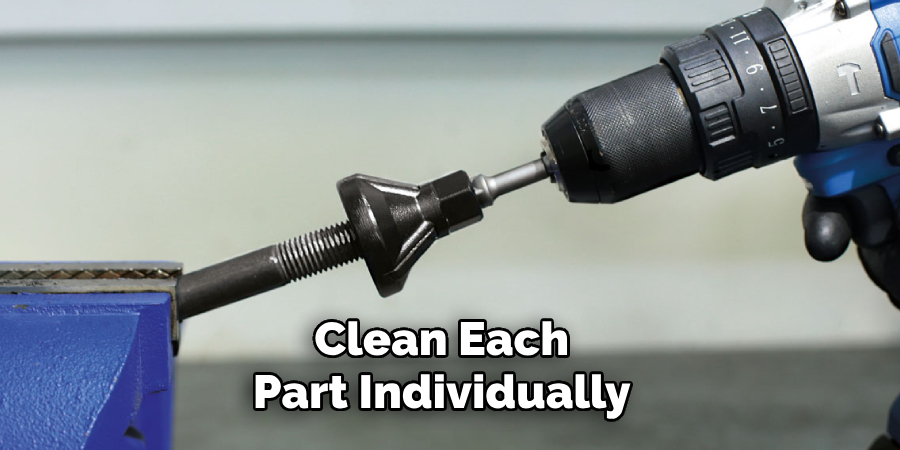

Step 5: Disassemble the Tool and Clean Individual Parts

If your pipe deburring tool is made up of multiple parts that can be disassembled, take this opportunity to clean each part individually. This step is crucial for ensuring all debris and buildup are removed from hard-to-reach areas, such as inside joints or crevices.

Use a mild cleaning solution and a soft-bristle brush to thoroughly clean each part before drying them completely with a clean cloth. Be sure to reassemble the tool correctly once it’s completely dry.

Step 6: Check for Any Damaged or Worn Parts

After cleaning the tool, carefully inspect it for any signs of damage, such as cracks, chips, or worn-out cutting edges. Pay attention to the sharpness of the cutting elements, as dull edges can affect the tool’s performance and the quality of the deburring process. If you detect any issues, consider repairing or replacing the damaged parts to ensure the tool operates efficiently.

Regular inspection and maintenance can prevent further damage and prolong the lifespan of your pipe-debring tool.

Step 7: Lubricate Moving Parts

Lubricating the moving parts of your pipe deburring tool is essential to prevent rust and corrosion. Apply a few drops of lubricant, such as machine oil or silicone spray, to any joints, bearings, or gears that require lubrication. This step will ensure your tool continues to operate smoothly and efficiently.

You can also lubricate the cutting edges if they are made of metal to prevent rust and ensure a smooth, clean cut.

Step 8: Store the Tool Properly

Once you’ve cleaned and lubricated your pipe deburring tool, it’s essential to store it properly. If possible, keep the tool in its original packaging or a designated storage case. This step will protect the tool from dust, moisture, and other elements that could damage it.

Avoid storing the tool in areas with high humidity or extreme temperatures.

Step 9: Keep a Maintenance Schedule

To maintain optimal performance, it’s crucial to establish a regular maintenance schedule for your pipe deburring tool. Depending on how frequently you use the tool, this could range from monthly to quarterly cleanings.

Keeping a maintenance schedule will also help you detect any issues or worn parts before they become severe and require costly repairs or replacements.

Step 10: Follow Manufacturer’s Instructions

Finally, always refer to the manufacturer’s instructions for specific cleaning and maintenance guidelines for your pipe deburring tool. Following these instructions will ensure you are using the correct methods and solutions for cleaning your specific tool.

Regular maintenance and proper cleaning techniques are essential for keeping your pipe-deburring tool in good working condition. By following these 10 steps on how to clean pipe deburring tool, you can prolong the lifespan of your tool and ensure it continues to perform efficiently for all your deburring needs. So, make sure to regularly clean and maintain your pipe deburring tool according to the manufacturer’s instructions for optimal results. Happy deburring!

Additional Tips

- If you’re unsure about how to clean your specific pipe deburring tool, reach out to the manufacturer for guidance.

- Wear protective gear, such as gloves and safety glasses, when handling or cleaning the tool.

- Avoid using harsh chemicals or abrasive materials that could damage the tool’s surface. Stick to mild cleaning solutions and soft-bristle brushes.

- Regularly check the sharpness of the cutting edges and replace them if necessary for efficient deburring.

- Properly dispose of any used cleaning materials and solutions according to local regulations. Overall, proper maintenance and regular cleanings will not only extend the life of your pipe deburring tool but also ensure safe and efficient operation every time.

Frequently Asked Questions

Q1: What Should I Do Before Cleaning My Pipe Deburring Tool?

A: Before cleaning your pipe deburring tool, always disconnect it from any power source and remove any attached accessories. This will prevent accidental activation of the tool and ensure a thorough cleaning.

Q2: How Often Should I Clean My Pipe Deburring Tool?

A: The frequency of cleaning your pipe deburring tool will depend on how frequently you use it. As a general rule, aim to clean the tool at least once every 1-3 months. However, if you use the tool more frequently or in harsher conditions, consider cleaning it more often.

Q3: Can I Use Cleaning Solutions Other Than Mild Detergent?

A: It’s best to stick with mild detergents when cleaning your pipe deburring tool. These solutions are gentle enough not to

damage any delicate parts of the tool while effectively removing dirt and grime. Avoid using harsh chemicals or solvents, as they can potentially damage the tool’s surface and components.

Q4: Can I Sharpen My Pipe Deburring Tool?

A: It’s not recommended to sharpen your pipe deburring tool yourself, as it requires specific skills and equipment. If you notice the cutting edges are dull or damaged, consider sending it to a professional for sharpening or replacing the blades if necessary.

Conclusion

Proper cleaning and maintenance of your pipe deburring tool are essential for ensuring its longevity and optimal performance. By following the steps outlined in this guide on how to clean pipe deburring tool, you can keep your tool in excellent condition, reduce the need for costly repairs, and achieve clean, precise results every time you use it.

Remember to clean, inspect, lubricate, and store your tool properly while adhering to the manufacturer’s guidelines. A well-maintained pipe deburring tool not only enhances efficiency but also guarantees safety during use. Make maintenance a part of your routine and enjoy reliable performance for years to come.