Pipe benders are essential tools used for shaping pipes and tubes to specific angles without collapsing or damaging them. Whether you are working on plumbing, construction, or a DIY project, understanding how to properly operate a pipe bender ensures precision and efficiency.

This guide on how to operate a pipe bender will walk you through the basic steps, safety tips, and best practices for using a pipe bender effectively.

Why Use a Pipe Bender?

Using a pipe bender is crucial for achieving clean and accurate bends in pipes and tubes, which is essential in many industries and applications. Unlike manual bending methods, which can lead to uneven bends, cracks, or deformation, a pipe bender ensures consistency and precision.

This tool allows users to create custom angles tailored to their project needs, whether for plumbing installations, metal fabrication, or even artistic designs. Additionally, pipe benders reduce material waste and ensure the structural integrity of the pipe, making them both a practical and cost-effective solution.

Needed Materials

Before operating a pipe bender, you will need to gather some necessary materials. These include:

Pipe Bender (Manual or Hydraulic):

The type of pipe bender you choose will depend on the size and material of the pipe or tube you are bending.

Pipe Bender Dies:

These are interchangeable pieces that fit onto the pipe bender to create different angles and sizes. Make sure you have the appropriate dies for your project.

Pipes or Tubes:

Choose pipes or tubes with suitable dimensions and materials for your desired bend. Consider factors such as wall thickness, material strength, and diameter when selecting your pipes.

8 Step-by-step Guides on How to Operate a Pipe Bender

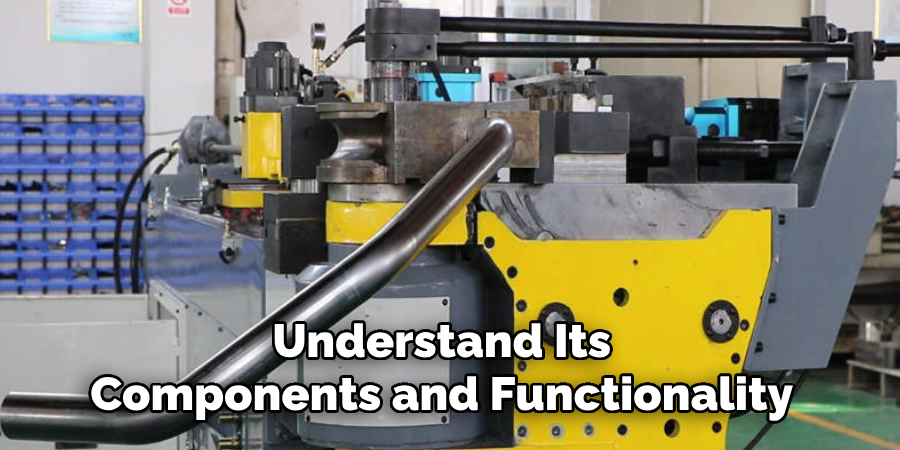

Step 1: Familiarize Yourself with the Pipe Bender

Before using a pipe bender, take time to understand its components and functionality. Most pipe benders consist of a mainframe, bending lever, and interchangeable dies. Examine the instruction manual for your specific pipe bender to understand its features and capabilities. Identify the parts of the tool, such as the die, clamp, and rollers, and learn how they work together to create a bend.

Ensure you are comfortable with adjusting and securing the dies, and practice operating the lever or hydraulic mechanism if applicable. Familiarizing yourself with the tool ahead of time will simplify the bending process and reduce the chances of errors or accidents.

Step 2: Measure and Mark the Pipe

Accurate measurement is essential for achieving precise bends. Use a measuring tape to determine where the bend should start along the pipe or tube. Mark this point clearly with a marker or chalk to ensure it remains visible during the bending process. If you need to create multiple bends or specific angles, mark each location accordingly.

Double-check your measurements to avoid errors, as even small inaccuracies can impact the overall result. Proper measurement and marking will guide the bending process and help produce professional-quality results.

Step 3: Secure the Pipe in Place

Once you have measured and marked the pipe, securely position it within the pipe bender. Align the marked point with the designated area on the die where the bend will occur. Use the clamps or locking mechanism on the pipe bender to hold the pipe firmly in place to prevent any movement during the bending process.

Ensuring that the pipe is properly secured is crucial for achieving a precise and uniform bend. Take a moment to verify that everything is set correctly before proceeding to the next step.

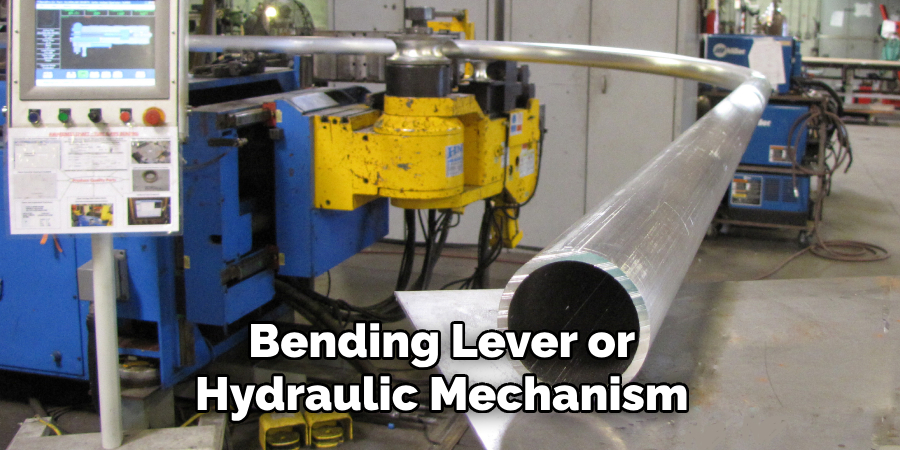

Step 4: Begin Bending the Pipe

Depending on your pipe bender type, use the bending lever or hydraulic mechanism to start creating the bend. Slowly and steadily move the handle while keeping an eye on the pipe for any signs of damage or irregularities. Make sure to apply even pressure throughout the process to avoid kinks or creases in the pipe.

Note that different materials may require different levels of force, so be cautious and follow manufacturer guidelines accordingly. Continue bending until you have reached your desired angle or completed multiple bends as needed.

Step 5: Release Pressure and Inspect the Bend

Once you have completed the bending process, release any pressure from the lever or hydraulic mechanism and carefully remove the pipe from the bender. Inspect the bend for any deformities or inconsistencies, such as creases, flat spots, or uneven angles.

If any issues are present, you may need to re-bend the pipe or adjust your technique for future bends.

Step 6: Remove the Pipe Bender Dies

After ensuring that the pipe is bent to your desired angle and is free of defects, the next step is to remove the dies from the pipe bender. Begin by loosening any clamps or securing mechanisms that are holding the dies in place. Carefully slide the dies out of the pipe bender, ensuring no damage to them or the bent pipe during this process.

Inspect the dies for any signs of wear or debris and clean them if necessary to maintain their condition. Properly store the dies in their designated place for future use. Removing and maintaining the dies ensures the pipe bender is ready for your next project and contributes to its long-term functionality.

Step 7: Prepare the Pipe for Use

Now that your pipe is bent, additional preparation may be required before you can use it in your project. This may include deburring, sanding, or other finishing techniques to remove rough edges and ensure a smooth surface.

Take time to inspect the bend once again to ensure it meets any necessary specifications or standards for your project. Making any necessary adjustments at this stage will save time and resources later on.

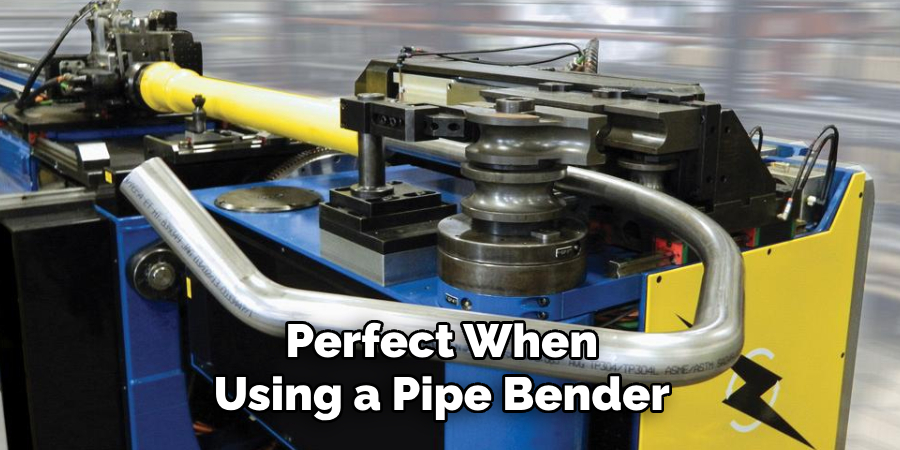

Step 8: Practice Makes Perfect!

As with any new skill or tool, practice makes perfect when using a pipe bender. Take time to familiarize yourself with the bending process and make adjustments as needed until you feel comfortable and confident in your abilities.

As you gain experience, you can experiment with different materials, angles, and techniques to create a wider range of bends. Remember to always follow safety precautions and manufacturer guidelines on how to operate a pipe bender when operating a pipe bender.

Additional Tips for Operating a Pipe Bender

- Always wear appropriate protective gear such as goggles, gloves, and closed-toed shoes when using a pipe bender.

- Make sure the bending area is clear of any obstacles or debris before beginning the process.

- Avoid putting excessive pressure on the lever or hydraulic mechanism to prevent damage to the tool or pipe.

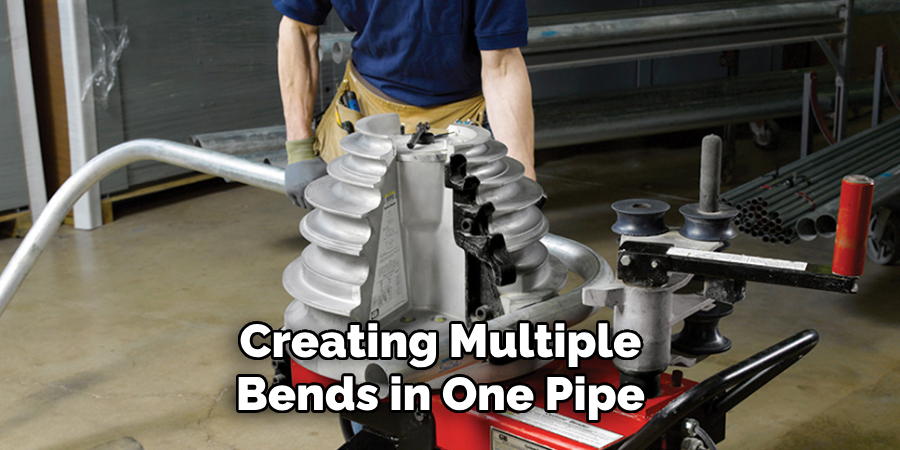

- When creating multiple bends in one pipe, it may be helpful to use a bending table or template to ensure consistent and accurate results.

- Keep the pipe lubricated during the bending process to prevent friction and potential damage.

- Regularly check and maintain your pipe bender to prolong its lifespan and ensure safe operation.

By following these steps and tips for operating a pipe bender, you can achieve professional-looking bends in pipes and tubes with ease. With practice, you can master this skill and utilize it for various projects that require precise bending. So don’t be afraid to pick up a pipe bender and get started on your next project today! Happy bending!

Frequently Asked Questions

Q1: Can You Bend Any Type of Pipe With a Pipe Bender?

A1: Pipe benders are designed to work with specific types and sizes of pipes. It is essential to check the manufacturer’s guidelines to ensure your pipe bender is suitable for the type of pipe you are bending.

Q2: Can I Create Multiple Bends in One Pipe?

A2: Yes, some pipe benders have features that allow for creating multiple bends in one pipe. However, it is crucial to take

extra care and follow proper techniques to avoid any damage or deformation to the pipe.

Q3: How Do I Know If My Pipe Bender Is Suitable for my Project Needs?

A3: It is essential to consider factors such as the type and size of pipes you will be working with, the level of precision required, and the frequency of use when choosing a pipe bender. It is always best to consult the manufacturer’s guidelines and seek professional advice if needed.

Q4: Can I Bend Pipes with Different Angles Using a Pipe Bender?

A4: Yes, pipe benders allow for creating bends at various angles depending on the type of pipe bender and the technique used. It is crucial to follow proper procedures and use caution, especially when creating sharp or tight bends.

Conclusion

Using a pipe bender effectively requires understanding the proper techniques, safety measures, and tools needed for the job. By following the step-by-step guide on how to operate a pipe bender outlined above and incorporating the additional tips provided, you can achieve accurate and professional-quality bends in your pipes. Whether you’re a beginner or an experienced craftsman, practice and patience are key to mastering this skill.

With time and effort, you’ll be able to confidently tackle a variety of projects that demand precise pipe bending. Remember, preparation and care ensure not just the quality of your work but also the longevity of your tools. Happy bending!