Insulating a pipe inspection camera is an essential process to ensure its durability and optimal performance in various environments. Whether you are working in extreme temperatures or handling potentially abrasive conditions, proper insulation protects the camera from damage and helps maintain accurate imaging.

This guide on how to insulate a pipe inspection camera will walk you through the necessary steps and materials needed to effectively insulate your pipe inspection camera. With the right approach, you can extend the lifespan of your equipment and ensure reliable functionality for future inspections.

Why Insulate a Pipe Inspection Camera?

A pipe inspection camera is a delicate piece of equipment that requires protection from external elements. Without proper insulation, the camera can be susceptible to damage from extreme temperatures, moisture, and abrasive materials.

Insulating your pipe inspection camera also helps maintain its accuracy and prevent distortion in imaging caused by temperature fluctuations.

Materials Needed

There are various materials you will need to effectively insulate your pipe inspection camera. These include:

High-density Foam:

This type of foam provides excellent insulation against extreme temperatures. It also provides cushioning and protection for the camera.

Waterproof Tape:

Waterproof tape is essential to seal any exposed areas of the camera to prevent moisture from entering. It is crucial in wet environments or when conducting underwater inspections.

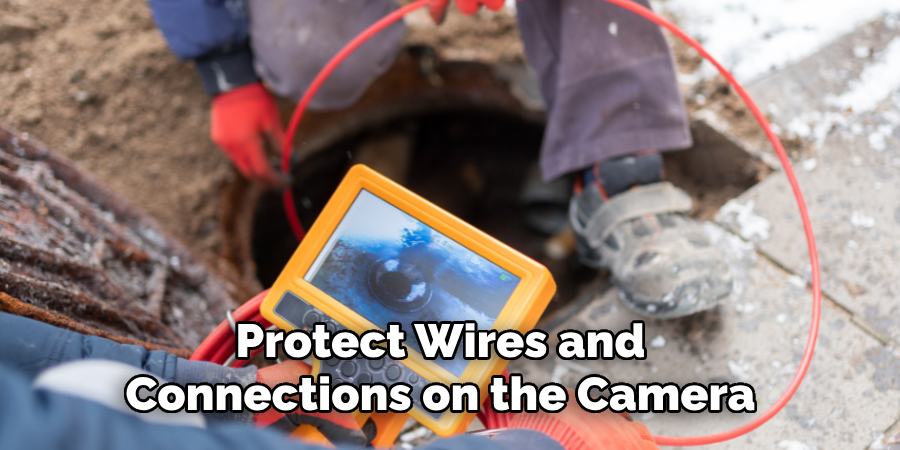

Heat-shrink Tubing:

Heat-shrink tubing is used to cover and protect wires and connections on the camera. This prevents damage from abrasion or exposure to extreme temperatures.

Electrical Tape:

Electrical tape can be used as an additional layer of insulation for wires and connections on the camera.

9 Steps on How to Insulate a Pipe Inspection Camera

Step 1: Prepare the Materials

Before you begin the insulation process, gather all the necessary materials listed above. Organize them in a clean, well-lit workspace to ensure easy access during the process. Inspect each material for any damage or defects that could compromise the insulation.

Measure the dimensions of your pipe inspection camera to ensure you have enough high-density foam, waterproof tape, heat-shrink tubing, and electrical tape to cover all necessary areas adequately. Having everything prepared beforehand will streamline the insulation process and help avoid interruptions.

Step 2: Turn off the Camera

Before proceeding with the insulation process, ensure that your pipe inspection camera is turned off and disconnected from any power source. This is a critical safety step to prevent any electrical hazards or accidental damage.

Allow the device to cool down if it has been in use, as working on a hot camera can lead to potential injury or reduced effectiveness of the insulation materials. Ensure the camera is in a stable position and accessible for the next steps of the process.

Step 3: Insulate the Wires and Connections

Using heat-shrink tubing, cover all exposed wires and connections on the camera. Cut the tubing to fit the length of each wire and connection, leaving a little extra for overlap. Use a heat gun or lighter to shrink the tubing in place, creating a tight seal. This step prevents any damage caused by exposure to extreme temperatures or abrasion.

You can also use electrical tape as an extra layer of insulation for added protection. Wrap it around the heat-shrink tubing and wires, ensuring there are no gaps or exposed areas.

Step 4: Insulate the Camera Body

Next, cut the high-density foam to fit the dimensions of your pipe inspection camera body. Ensure that all buttons, ports, and lenses are accounted for when measuring and cutting the foam. Use a sharp utility knife to cut precise edges and openings as needed.

Place the foam pieces onto the camera body in a way that provides complete coverage while still allowing access to necessary functions. Use waterproof tape to seal any gaps between individual pieces of foam for added protection against moisture.

Step 5: Insulate the Camera Head

Using the same process as above, cut high-density foam to fit the dimensions of your camera head. Make sure to account for any openings or moving parts that require access during inspections. Place the foam on top of the camera head and secure it with waterproof tape where necessary.

The camera head is the most sensitive part of the device, so take extra care to ensure it is adequately insulated and protected.

Step 6: Secure and Seal the Foam

Once all foam pieces are in place, use waterproof tape to secure them securely. Ensure that there are no loose or exposed areas that could compromise the insulation.

Double-check all edges and openings to make sure they are adequately sealed against moisture or external elements.

Step 7: Test for Functionality

Before proceeding with any inspections, test your camera’s functionality to ensure everything is working correctly after the insulation process. Check buttons, ports, and lenses to verify they are still accessible and responsive.

If you encounter any issues, go back and adjust the foam or tape to provide better coverage while still allowing functionality.

Step 8: Store Properly

When not in use, it is essential to store your pipe inspection camera correctly. Keep it in a dry, temperature-controlled environment to prevent damage from moisture or extreme temperatures.

Ensure that the camera is protected from impact or other potential hazards that could compromise its insulation.

Step 9: Regular Maintenance

To maintain the effectiveness of your insulation, regularly inspect and clean your pipe inspection camera. Check for any wear and tear on the foam or tape and replace it as needed. Ensure all connections are secure and free from debris that could affect functionality.

Regular maintenance will extend the life of your camera and ensure it continues to provide accurate and reliable inspections.

Following these steps on how to insulate a pipe inspection camera will help you effectively insulate your pipe inspection camera and protect it from potential damage. Proper insulation is crucial for ensuring the longevity and functionality of this essential inspection tool. With the right materials and techniques, you can confidently use your camera in various environments without fear of compromising its performance. So, make sure to follow these steps and keep your pipe inspection camera well-insulated for optimal use. Remember, prevention is always better than cure when it comes to expensive equipment. Happy inspecting!

Do You Need to Use Professionals?

While insulating a pipe inspection camera can be a manageable task with the proper materials and instructions, there are situations where seeking professional assistance may be the better choice. If you are unfamiliar with handling insulation materials or concerned about damaging the camera during the process, consulting a professional can ensure the job is done correctly and efficiently.

Professionals have the expertise, tools, and experience required to provide high-quality insulation for sensitive equipment like pipe inspection cameras. They can also help identify and address specific areas of concern based on your usage environment, such as extreme temperatures, excessive moisture, or heavy wear and tear.

Additionally, if your camera is under warranty, it is essential to confirm whether performing insulation work yourself might void the warranty terms. Using an authorized professional could help maintain your warranty while ensuring your equipment is adequately protected.

Frequently Asked Questions

Q1: Can I Use Any Type of Foam for Insulation?

A: It is best to use high-density foam specifically designed for insulation purposes. Regular foam may not provide the same level of protection and durability. It is also essential to ensure the foam is waterproof and heat-resistant.

Q2: How Often Should I Inspect and Clean My Pipe Inspection Camera?

A: Regular maintenance and cleaning should be done after every use. Inspect the foam and tape for any damage or wear and tear and replace as needed. It is also essential to clean the camera lenses, ports, and connections to ensure optimal functionality.

Q3: Can I Perform Inspections in Extreme Temperatures After Insulating My Camera?

A: While proper insulation can provide some protection against extreme temperatures, it is still recommended to avoid using your pipe inspection camera in extremely hot or cold environments. Exposure to these conditions can affect both the performance of the device and its insulation.

Q4: How Do I Know if My Camera Needs Reinsulation?

A: If you notice any damage or wear on the foam or tape, it is best to replace it immediately. Inspect and clean your camera regularly to ensure the integrity of its insulation. If you encounter any issues during inspections, such as reduced functionality or exposure to extreme temperatures, it may be time for reinsulation. Always inspect and maintain your camera to ensure peak performance.

Conclusion

Insulating your pipe inspection camera is essential for protecting its functionality, especially in extreme temperatures or wet environments. With the right materials and proper steps on how to insulate a pipe inspection camera, you can effectively insulate your camera and extend its lifespan. Remember to always prioritize safety by turning off and disconnecting your camera before insulating it.

Regular maintenance is also crucial for ensuring the continued effectiveness of the insulation. Keeping these steps in mind will help you confidently use your pipe inspection camera in various settings without worrying about potential damage. Happy inspecting!