For those of you familiar with HVAC components, dampers are an essential piece to understanding how air flows conditionally throughout a duct. Essentially, dampers are mechanical plates used in ducts as part of airflow control systems – but where do they fit into the overall puzzle?

Understanding what purpose these panels serve is key if you want to know how your ventilation system works and make sure it operates at optimal efficiency. In this blog post on how to find dampers in ductwork, we’ll explore what exactly dampers do, where they fit in relation to the other parts of ductwork, and why it’s important for them to be correctly sized and positioned within your overall HVAC system.

What are Dampers in Ductwork?

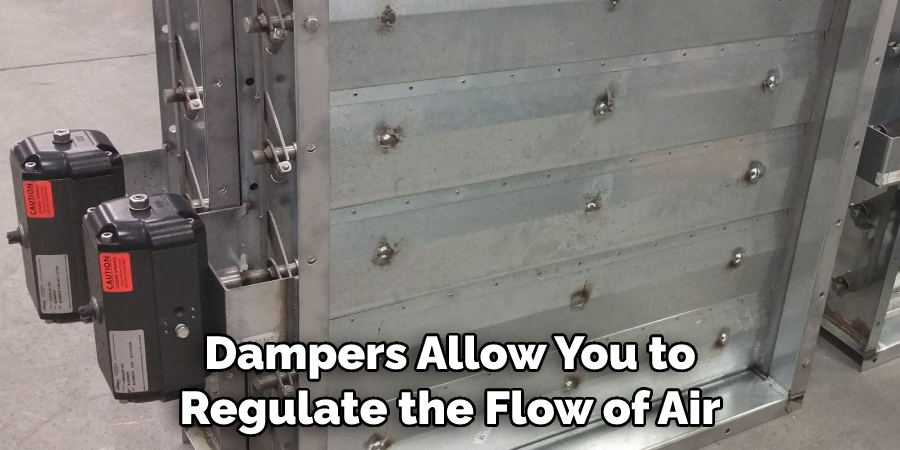

Dampers are panels used to control the flow of air in a duct. They can be used to regulate the amount of air that is passed through a given space, as well as direct it into specific areas. This gives you more precise control over the airflow in your HVAC system and helps maintain optimal temperatures throughout your home or workplace.

In some cases, dampers in ductwork can also be used to prevent the spread of fire or smoke. This is done by closing off certain ducts and preventing air from flowing through them, which will contain the fire and reduce the risk of it spreading throughout your home or workplace.

Where do Dampers Fit into HVAC Systems?

Dampers are placed within the ductwork, usually at the point where air enters or exits the system. They can be manually operated with a lever or wheel, but many have automated controls that allow you to control them remotely or programmatically via an HVAC controller.

The position and size of dampers play an important role in the overall efficiency of your system. A damper that is too small or positioned incorrectly can create turbulence and restrict airflow, which will lead to inefficient operation and higher energy bills.

Why are Dampers Important?

Dampers allow you to regulate the flow of air within a duct, which gives you more precise control over your HVAC system. This enables you to maintain more consistent temperatures throughout your home or workplace, as well as reduce energy costs by eliminating wasted air from the system.

Installing dampers in ductwork is a simple and cost-effective way to improve the efficiency of your HVAC system and make sure it operates at peak performance.

Required Materials

To find dampers in ductwork, you will need the following materials:

- Flashlight

- Tape measure

- Screwdriver or drill

- Ladder (if necessary)

10 Steps on How to Find Dampers in Ductwork

Step 1: Inspect

Inspecting the Ducts for Dampers. Start by inspecting the ducts for dampers. Look closely for any signs of dampers, such as metal plates or discs. Inspecting the ducts with a flashlight can help to find any hidden dampers.

Step 2: Measure

Measure the inside of the ducts to determine their length and width. This will make it easier to locate where the dampers might be located along the walls of the ductwork. The right measurements can also help you determine the size of dampers that will be needed to fit into the ducts.

Step 3: Locate

Locate any potential dampers by looking for metal plates or discs on the walls of the ductwork. If there are none in sight, then look further down in the ducts to see if any dampers have been installed.

Step 4: Remove

If you locate a damper, use a screwdriver or drill to remove it from the ducts. Be careful not to damage the ductwork in the process. Removing is important if you need to replace the damper or make any other repairs.

Step 5: Replace

If the damper is damaged, replace it with a new one. Make sure to purchase the right size and type of damper for your ductwork. This will ensure that the dampers will fit properly and work correctly.

Step 6: Install

Install the new damper into the ducts. Make sure it is secured tightly and that none of its parts are exposed to allow debris or other objects to enter the ductwork. It is also important to make sure the damper is properly adjusted so that it will function correctly.

Step 7: Test

Once the dampers are installed, test them to make sure they are working properly. Open and close the dampers a few times to see if they move freely without any difficulty. This will help you determine if there is anything wrong with the dampers and if any repairs are needed.

Step 8: Clean

Clean up any debris or dust that was created while installing the dampers. This will help keep your ducts free from dirt and other particles that could cause problems if they accumulate inside the system.

Step 9: Maintain

Maintain the dampers by regularly checking to make sure they are functioning correctly. Also, inspect the dampers for any signs of wear and tear so that you can replace them when necessary.

Step 10: Secure

Finally, secure all dampers with screws or bolts to make sure they stay in place and do not get dislodged during operation. This will help ensure that the dampers are able to do their job efficiently and will last for a longer time.

Following these steps on how to find dampers in ductwork can help you identify and install them properly, allowing your system to operate at its best. Additionally, regular maintenance of the dampers can prevent any problems from arising in the future. With the right tools and knowledge, you can easily find and install dampers in your ductwork.

8 Safety Precautions to Take

1. Wear proper safety equipment, such as protective eyewear and gloves to protect yourself from any potential hazards. Don’t forget to also wear a face mask and ear protection.

2. Make sure you are aware of your surroundings when locating dampers in ductwork. Look for signs of dust, debris, or other hazards that may be present. Dirt always accumulates in hard-to-reach places, so make sure you’re careful when maneuvering around.

3. Consider hiring a professional if the dampers are difficult to access or if they are located in an area that’s potentially hazardous. Hiring a professional will help ensure the job is done safely and properly.

4. Make sure all circuit breakers are turned off before, during, and after working on the dampers. This will prevent any electrical shock or injury from occurring.

5. Check for loose wires or connections that could cause a short circuit when attempting to locate dampers in ductwork. If you do find any loose wires, make sure you disconnect them and reconnect them properly.

6. Use a flashlight or a headlamp to illuminate dark areas of the ductwork when searching for dampers. This will make it easier for you to see where the dampers are located. Flashlight batteries should also be checked to ensure they are in good working condition.

7. When disconnecting wires, make sure you label them clearly so you know where each one is meant to go when reconnecting. This will help prevent any confusion or mistakes when replacing the dampers.

8. Make sure all necessary tools and equipment are available before beginning the job. This includes screwdrivers, wrenches, pliers, and any other items that may be needed to work on the dampers in ductwork.

Follow these 8 safety precautions when attempting to find dampers in ductwork. Taking the necessary precautions will ensure a safe and successful job. If you have any questions or concerns, it is best to consult a professional contractor or HVAC technician. That way, you can be sure that the job is done properly and safely.

Frequently Asked Questions

How Long Will It Take to Finish the Project?

The amount of time it takes to find dampers in the ductwork will depend on the size and complexity of the system. Generally, a small system can take two or three hours.

Larger systems could take significantly longer since every component must be inspected to locate the damper. It is important to have an experienced technician who knows what to look for to ensure the project is completed efficiently and accurately.

How Often Should You Repair the Dampers in Ductwork?

Dampers should be inspected regularly to determine if there are any signs of damage or wear. They should also be repaired or replaced immediately upon discovery of a problem. Regular maintenance is important to ensure that the damper is functioning properly and efficiently, as well as keeping your HVAC system running safely and smoothly.

Can You Install Dampers in Ductwork Yourself?

Yes, you can install dampers in ductwork yourself. However, it is important to remember that this is a job that requires skill and knowledge. If you are not comfortable or familiar with the process, it’s best to call in a professional contractor or HVAC technician to help ensure the safety of your system.

Conclusion

To sum up, identifying dampers in ductwork doesn’t have to be a tall order. Using sight, sound, and smell as clues can help you get a better idea of where these components may be hiding. In addition to this, researching the blueprints is essential; they should show all of the dampers that were originally installed in the design phase.

Afterward, specific testing tools such as manometers or thermometers can be utilized, letting you confirm that each damper is indeed in its proper place. Utilizing these steps on how to find dampers in ductwork methodically should let you pinpoint any hidden dampers with relative ease!

Remember: it’s important to perform routine tests and inspections on your dampers to ensure they are operating correctly; This will save energy and increase efficiency while keeping everything running optimally. With all of this information at our disposal, we can now work towards successfully finding dampers in our ductwork!

You Can Also Check This Out to Measure Undermount Sink Size