Flow regulators play a critical role in various systems, including water supply, HVAC, and industrial applications, by ensuring that fluids are delivered consistently and optimally. The primary function of a flow regulator is to control the flow rate of liquids and gases, adapting to changes in pressure and demand.

This is essential for maintaining system efficiency and performance, as fluctuations in flow can lead to inefficiencies, potential damage, and increased operational costs. Understanding how does a flow regulator work is crucial for anyone involved in the management of fluid systems.

Key aspects include the regulator’s components, such as valves and sensors, and their specific applications across different industries. These devices contribute significantly to energy savings, system reliability, and overall operational effectiveness by effectively managing flow rates.

What is a Flow Regulator?

Definition

A flow regulator is a device designed to control the fluid flow rate within a system, ensuring that a consistent flow rate is maintained despite fluctuations in pressure or demand. By automatically adjusting the flow based on varying conditions, flow regulators prevent issues like over-pressurization, system surges, and inefficiencies that can arise in both liquid and gas applications.

Types of Flow Regulators

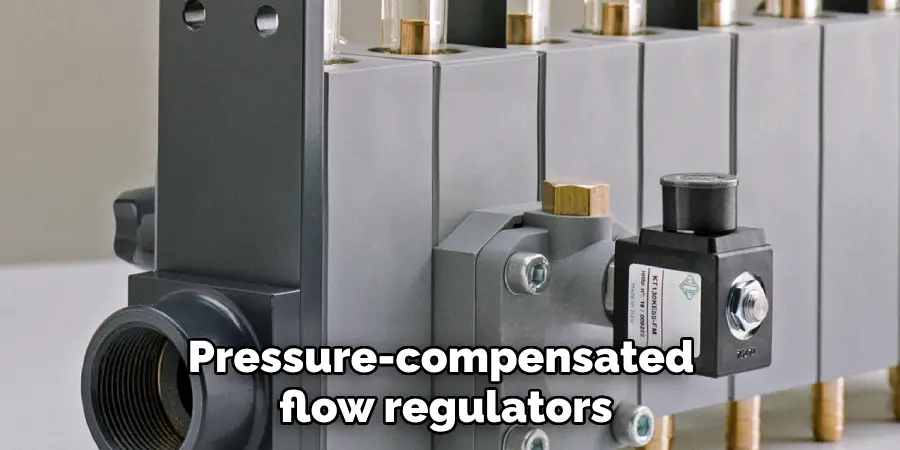

There are several types of flow regulators, each serving specific functions in various applications. Pressure-compensated flow regulators are commonly used when a constant flow must be maintained regardless of changes in inlet pressure. Flow-control valves offer manual or automatic regulation capabilities, making them versatile for various systems.

Electronic flow regulators, equipped with sensors and control systems, provide precise flow management and real-time adjustments, often used in complex industrial applications.

How Does a Flow Regulator Work: Components of a Flow Regulator

Regulating Mechanism

The main components of a flow regulator include the regulating mechanism, which typically consists of valves, diaphragms, or pistons. These components work together to adjust the flow rate in response to changing conditions within the system. For instance, in diaphragm-based regulators, the diaphragm flexes to open or close the valve, thereby modulating fluid flow based on the pressure differential. This mechanical adjustment ensures a consistent flow rate is maintained, regardless of fluctuations in pressure or demand.

Sensors and Controls

Sensors and control systems are critical in monitoring and adjusting the flow rate within a regulator. These sensors detect variations in parameters such as pressure, temperature, and flow, relaying this information to the control system.

The system can make real-time adjustments to the regulating mechanism through advanced electronic controls, ensuring that the desired flow settings are achieved. Integrating sensors and controls enhances operational efficiency and accuracy in maintaining optimal flow rates.

How Flow Regulators Work

Basic Operation

Flow regulators operate on a straightforward principle: they adjust the flow of fluid based on changes in pressure or a system’s specific flow rate requirements. As pressure fluctuates or as demand for fluid changes, the regulator responds by modifying the flow area to either increase or decrease the fluid flow, ensuring that a consistent rate is maintained. This is crucial in applications where precise fluid control is vital for optimal operation.

Pressure-Compensated Flow Regulators

Pressure-compensated flow regulators are designed to maintain a constant flow rate even when variations in the inlet pressure occur. They achieve this by employing internal mechanisms, such as diaphragm systems or spring-loaded valves, which adjust the flow area in response to the pressure changes. By ensuring that the flow remains steady despite external fluctuations, these regulators protect equipment from damage due to over-pressurization and enhance the system’s overall efficiency.

Flow-Control Valves

Flow-control valves regulate fluid flow by adjusting the valve opening. This can be done manually by an operator or automatically through a control system. By altering the size of the valve opening, flow-control valves effectively maintain the desired flow rate. These valves are particularly valuable in applications that require changes in flow based on operational demands, allowing for flexibility and precision in fluid management.

Electronic Flow Regulators

Electronic flow regulators take flow management a step further by integrating sensors and electronic controls into their design. These systems continuously monitor various parameters, such as pressure and flow rate, allowing for real-time adjustments through feedback loops.

By utilizing electronic controls, these regulators can make precise changes to the flow in response to dynamic system demands, ensuring optimal performance and energy efficiency across complex industrial settings.

Applications of Flow Regulators

Water Supply Systems

Flow regulators are critical in both residential and industrial water supply systems, ensuring a steady and reliable water pressure and flow. By adjusting for fluctuations in demand and pressure, these devices maintain a consistent water supply, preventing issues such as low water pressure during peak usage times and over-pressurization that can lead to pipe damage.

HVAC Systems

In HVAC systems, flow regulators control airflow and maintain balanced temperature distribution throughout a building. By regulating air flow in ducts, these devices help achieve desired temperatures in different areas, enhancing comfort while reducing energy consumption.

Industrial Processes

Flow regulators are widely employed in various industrial processes to manage the flow of chemicals, gases, and other fluids. They ensure accurate and consistent material delivery, which is essential for maintaining process efficiency and safety. By preventing over-flow or under-flow scenarios, these regulators contribute to optimal production conditions in manufacturing environments.

Benefits of Using Flow Regulators

Improved Efficiency

Flow regulators significantly enhance system efficiency by maintaining consistent flow rates regardless of fluctuations in pressure or demand. This stability ensures that systems operate at optimal performance levels, reducing energy consumption. By preventing overflows and drips, flow regulators also minimize waste, allowing for better resource utilization. Consequently, these devices contribute to cost savings, both in terms of energy used and materials consumed, ultimately improving the overall productivity of operations.

Extended Equipment Life

Proper flow regulation plays a crucial role in extending the life of equipment. By controlling and maintaining a stable fluid flow, flow regulators help to reduce wear and tear on critical components, such as pumps and valves. With diminished strain and operational stress, these devices limit the frequency of repairs and maintenance, consequently lowering overall maintenance costs. As a result, businesses can enjoy increased reliability and a longer service life for their equipment, translating to improved operational continuity and reduced downtime.

Common Issues and Troubleshooting

Inconsistent Flow Rates

One of the most common issues with flow regulators is inconsistent flow rates, which may be attributed to blockages, worn components, or incorrect settings. Troubleshooting should begin with a visual inspection of the system, looking for any blockages in pipes or filters that may hinder the flow. Additionally, valves and sensors should be checked for proper functionality to ensure they respond accurately to system demands.

Maintenance Requirements

Regular maintenance is essential for the optimal performance of flow regulators. This includes routine cleaning to remove debris or buildup that can affect the operation and periodic inspections to ensure all components are functioning as intended. By maintaining flow regulators, users can avoid major breakdowns and prolong the system’s lifespan.

When to Seek Professional Help

If troubleshooting does not resolve persistent flow issues, it may be necessary to consult a professional. Expert technicians can accurately diagnose underlying problems and recommend appropriate repairs or replacements, restoring the flow regulation system to optimal working conditions.

Frequently Asked Questions (FAQs)

What Is the Purpose of A Flow Regulator?

Flow regulators are designed to maintain a consistent flow rate of fluids in various systems, protecting equipment from damage and ensuring optimized performance regardless of fluctuations in pressure.

How Do I Know if My Flow Regulator Is Working Correctly?

Signs of an improperly functioning flow regulator may includErratic flow rates, unusual noises, or fluctuations in pressure may be signs of an improperly functioning flow regulator erratic flow rates, unusual noises, or fluctuations in pressure. Regular inspections and monitoring of these parameters can help determine if your flow regulator is operating as intended.

Can Flow Regulators Be Repaired, or Do They Need to Be Replaced?

Depending on the issue, many flow regulators can be repaired. Common repairs include replacing worn components or cleaning blockages. However, if the regulator is significantly damaged or outdated, replacement may be more cost-effective in the long run.

How Often Should Flow Regulators Be Maintained?

Routine maintenance for flow regulators typically includes inspections and cleanings at least once or twice a year, depending on the application and operating conditions. More frequent checks may be necessary in systems with high fluid contamination or heavy usage.

Are Electronic Flow Regulators Better than Traditional Flow Regulators?

Electronic flow regulators offer more advanced control and precision, allowing for real-time adjustments and improved efficiency. However, the choice between electronic and traditional regulators depends on the system’s specific needs, including budget, complexity, and required performance levels.

Conclusion

In summary, flow regulators play a crucial role in maintaining steady fluid flow within various systems, encompassing components such as mechanical flow regulators, flow-control valves, and electronic flow regulators that adaptively respond to changes in pressure and demand.

Their applications span across water supply systems, HVAC systems, and numerous industrial processes, ensuring optimal performance and efficiency. Understanding how does a flow regulator work is vital, as these devices contribute significantly to improved system efficiency, prolonged equipment life, and enhanced operational safety. Proper flow regulation not only minimizes energy consumption and waste but also safeguards investment in infrastructure and machinery.

Therefore, it is essential for readers to recognize the importance of maintaining flow regulators regularly, as doing so ensures their systems operate at peak performance, leading to increased productivity and reduced downtime in various applications.