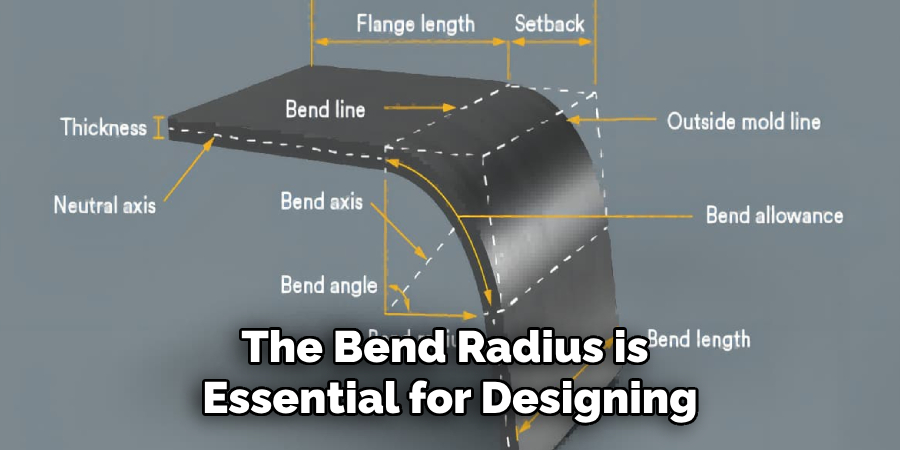

The bend radius is a critical concept in materials engineering, defined as the minimum radius at which a material can be bent without causing damage or deformation. This parameter is particularly significant in fields such as metalworking, piping, and engineering, where precision and material integrity are vital. Understanding the bend radius allows engineers and technicians to design and fabricate components that maintain their strength and functionality under stress.

Knowing how to calculate a bend radius accurately ensures that the material remains within its structural limits, preventing failures or compromising the quality of the finished product. This article aims to provide a comprehensive guide on how to calculate a bend radius, covering the essential formulas and methods needed for precise and reliable results. By mastering this knowledge, professionals can enhance the durability and performance of their designs, ultimately leading to safer and more efficient applications across various industries.

Understanding Key Concepts Related to Bend Radius

Bend Radius vs. Bend Diameter

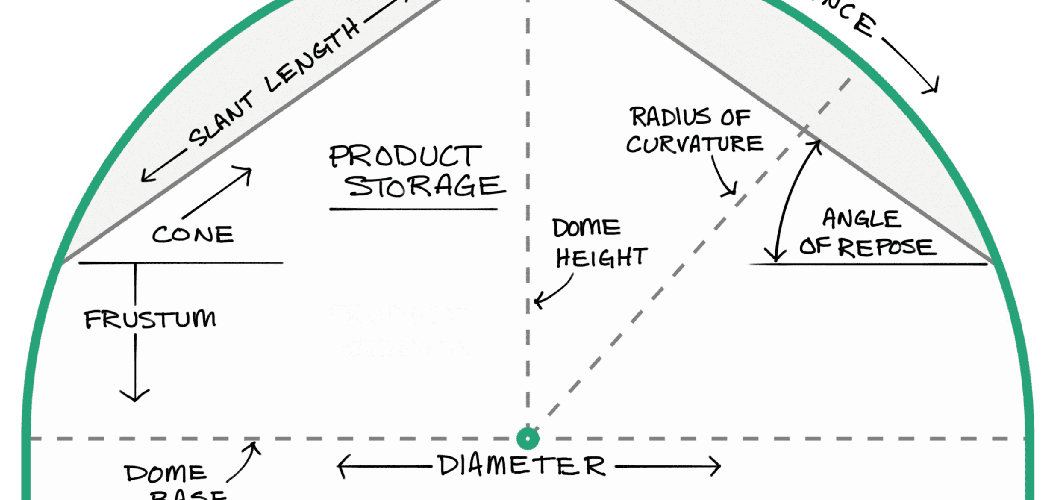

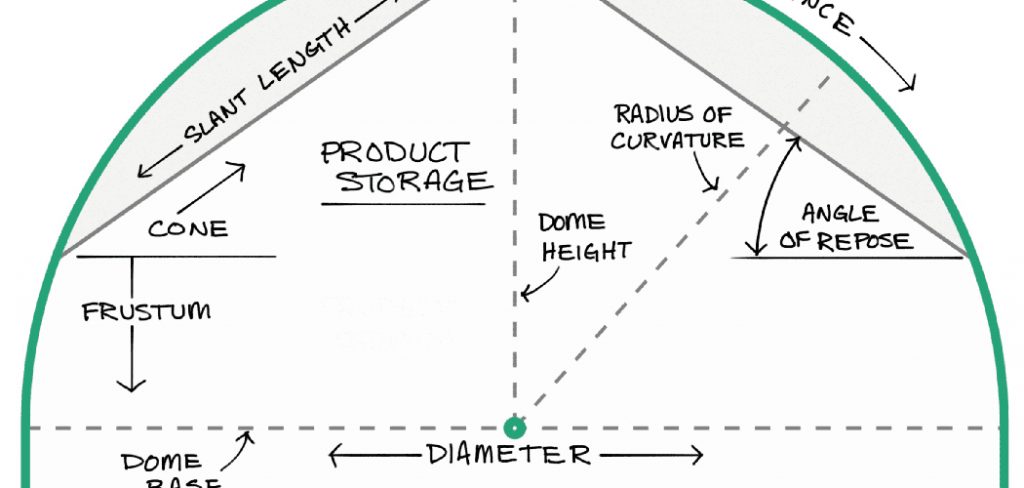

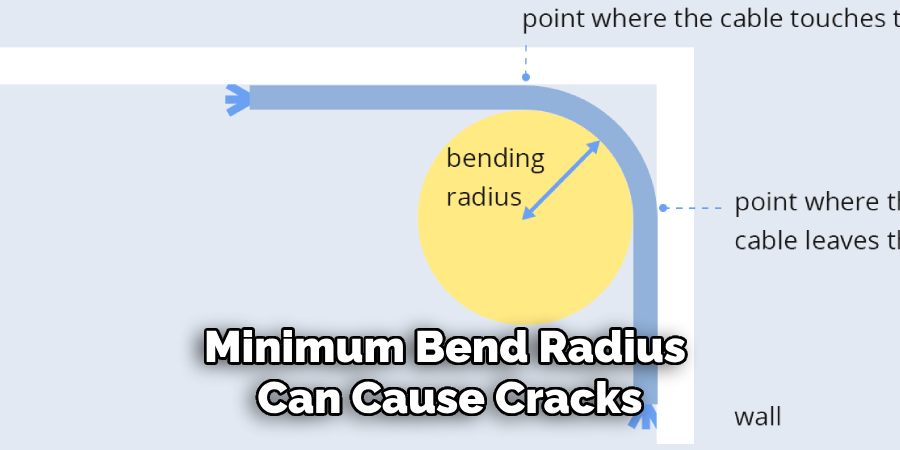

Understanding the distinction between bend radius and bend diameter is fundamental when working with materials needing bending. The bend radius refers to the distance from the centerline of the bend to the center of the curve, effectively indicating how tight or open a curve is. Conversely, the bend diameter is twice the bend radius, providing a guideline for the full width of the curve.

These measurements ensure that the material can be bent without compromising its integrity.

Material Factors

The type and thickness of the material significantly influence its ability to be bent without damage. Different materials, such as metals, plastics, and composites, each have unique properties that affect their bendability. Factors like ductility, which is the ability of the material to deform under tensile stress and tensile strength, or the resistance to breaking under tension, play a critical role.

Thicker materials or those with lower ductility may require larger bend radii to avoid cracking or breaking during bending.

Applications

Bend radius considerations are vital in various practical applications, notably in piping systems, sheet metal fabrication, and wiring. Proper understanding and calculation help maintain flow efficiency and system integrity in piping systems. Sheet metal work prevents stress concentration and potential failure. Similarly, in wiring, ensuring the appropriate bend radius prevents damaging insulation and ensures durability.

By understanding these concepts, professionals are better equipped to design and implement solutions in a range of industries.

How to Calculate a Bend Radius: Measuring Bend Radius for a Completed Bend

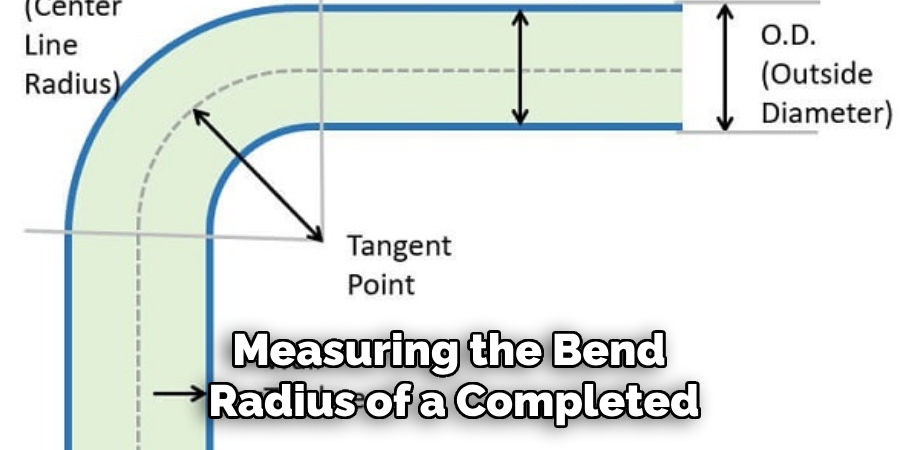

Accurately measuring the bend radius of a completed bend is crucial for ensuring that design specifications are met and the integrity of the material is maintained. The tools required for this task include a ruler, protractor, or a specialized radius gauge, each of which can help provide precise measurements.

Tools Required:

- Ruler: Essential for measuring straight distances.

- Protractor: Useful for accurately measuring bend angles.

- Specialized Radius Gauge: Designed specifically to measure arcs and curves with precision.

Steps to Measure:

- Identify the Center of the Bend and the Centerline of the Material:

- Carefully determine the curve’s mid-point, considering the bend’s symmetry.

- Locate the centerline, which runs along the length of the material.

- Measure the Distance from the Centerline to the Inner Edge of the Bend:

- Using a ruler or radius gauge, measure the shortest distance from the centerline to the innermost edge of the curve.

- Ensure Accurate Measurements for Precise Calculations:

- Double-check measurements to prevent errors that could lead to miscalculations.

- Utilize a protractor to verify any angles associated with the bend radius.

- When applicable, adjust the use of tools based on the curvature of the material to maintain accuracy.

By following these steps meticulously, technicians and engineers can confirm that the bend radius complies with design intentions and safeguards the material’s structural integrity.

How to Calculate a Bend Radius: Calculating Bend Radius Using the Bend Formula

Understanding how to calculate the bend radius is essential for designing materials that need bending without compromising their integrity. The fundamental formula used for this calculation is:

Bend Radius Formula:

\[ R = \frac{T}{\theta} \]

Where:

- \( R \) is the bend radius.

- \( T \) is the arc length, defined as the distance along the curved section.

- \( \theta \) is the angle of the bend in radians.

Converting Degrees to Radians

Since many bend angles are provided in degrees, it is crucial to convert these measurements into radians before using them in the formula. The conversion is done using the following equation:

\[ \text{Radians} = \frac{\text{Degrees} \times \pi}{180} \]

This conversion ensures the angle is aptly synchronized with the requirements of the bend formula for precise calculations.

Example Calculation

To illustrate the calculation of a bend radius, consider a hypothetical scenario where a material has an arc length (\( T \)) of 50 cm and a bend angle (\( \theta \)) of 60 degrees. Begin by converting the degrees into radians:

\[ \text{Radians} = \frac{60 \times \pi}{180} = \frac{\pi}{3} \approx 1.047 \text{ radians} \]

Once the angle is converted, apply the bend formula:

\[ R = \frac{50}{1.047} \approx 47.75 \text{ cm} \]

Thus, with a bend angle of 60 degrees and an arc length of 50 cm, the calculated bend radius is approximately 47.75 cm. This step-by-step calculation emphasizes the importance of accurate conversion and precise formula application to maintain material integrity and ensure functionality in any practical application.

Bend Radius Guidelines for Different Materials

Understanding the minimum bend radius for various materials is crucial when designing and fabricating components. Each material has its own characteristics influenced by factors such as strength, ductility, and thickness. Industry-standard bend radius charts provide valuable insights, offering recommended minimums for common materials like steel, aluminum, and PVC to avoid material failure during bending.

Minimum Bend Radius Charts

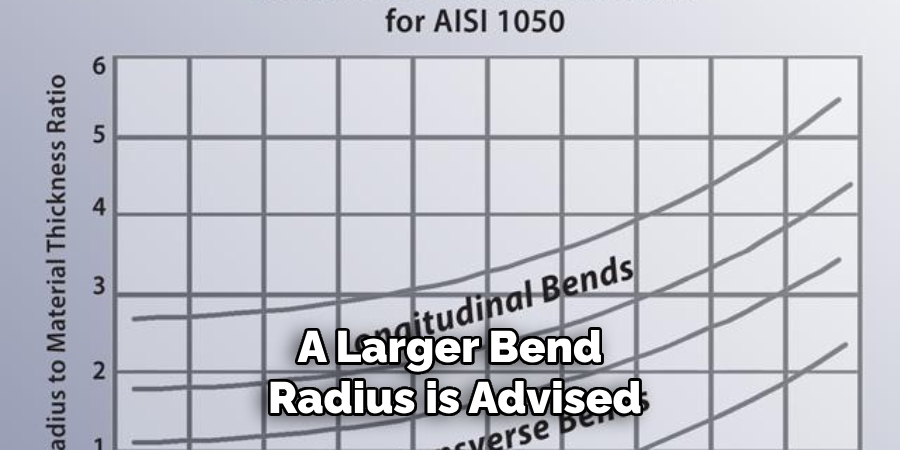

The minimum bend radius charts serve as critical references for engineers and designers. These charts outline the smallest radius to which a material can be bent without risking fractures, deformation, or compromising integrity. For example, steel, a popular material in construction and manufacturing, has a higher bend radius requirement compared to more pliable materials like PVC.

Steel’s rigidity necessitates consideration of thickness and grain direction, as bending against the grain can lead to cracks. Due to its malleability, aluminum presents more flexibility but, like all metals, requires careful handling to prevent stress fractures.

Material-Specific Considerations

Metals

The grain direction and thickness of metals play pivotal roles. Bending with the grain is generally recommended to enhance flexibility and prevent cracking. A larger bend radius is advised to distribute stress evenly across the material for thicker metals.

Plastics

Plastics are sensitive to heat and can become brittle, increasing the risk of cracking during bending. Adequate heating can reduce the bend radius, enhancing flexibility. However, care must be taken to avoid overheating, which could degrade the material.

Wires and Cables

The flexibility of wires and cables is determined by their core material and insulation thickness. Thinner insulation supports a smaller bend radius, facilitating tighter bends without damaging the internal conducting wires. For these materials, careful assessment of flexibility and resilience is essential to maintain functionality and reliability.

By adhering to these guidelines and understanding the properties of each material, professionals can design and fabricate components that meet performance standards while minimizing the risk of failure during bending operations.

Adjusting Bend Radius for Practical Applications

In practical applications, achieving the desired bend radius with precision is crucial, and using the right bending tools and jigs can make a significant difference. Tools such as pipe benders or press brakes are essential for setting specific bend radii. Pipe benders, for instance, allow for manual adjustments and use leverage to form precise curves, while press brakes use a die and punch system to exert uniform pressure across the material, allowing for more controlled bends.

Techniques like pre-heating or annealing metals are often employed to avoid material deformation during bending. Pre-heating reduces internal stress and makes metals more pliable, while annealing involves heating and then slowly cooling the metal to alter its microstructure, enhancing ductility and reducing hardness.

In custom applications, iterative adjustments may be necessary to achieve the perfect bend. This trial-and-error process involves making gradual changes, measuring, and testing the results to refine the bend and meet specific requirements. By employing these strategies and tools, professionals can ensure that the desired bend radius is achieved efficiently, maintaining the material’s integrity and functionality.

Such meticulous control is vital for applications where precise bends determine fabricated components’ overall performance and reliability.

Common Mistakes and How to Avoid Them

One common error when working with bend radii is misinterpreting the difference between bend radius and bend diameter. The bend radius refers to the curvature from the inside of the bend, whereas the diameter encompasses the total distance across the bend. This confusion can lead to incorrect calculations and flawed designs. Always double-check specifications and use clear terminology when documenting designs to avoid this.

Another frequent mistake is the use of incorrect tools for the material type or thickness. Each material requires specific tools to achieve a precise bend without damage. Selecting the right bending equipment, such as a pipe bender for metals or a heat bender for plastics, ensures accurate results.

Exceeding a material’s minimum bend radius can cause cracks or deformation, compromising structural integrity. To prevent this, adhere strictly to industry-standard charts and guidelines, considering material properties and thickness to ensure safe and effective bending operations.

Conclusion

Understanding how to calculate a bend radius is essential for ensuring the durability and functionality of fabricated components. Accurate calculations prevent material damage and structural failure, allowing for precise and reliable bends. Utilizing proper tools and techniques tailored to each material’s specific characteristics is crucial in achieving desired outcomes.

Always consult material-specific guidelines to ensure compliance with industry standards. For critical applications, seeking professional guidance can provide additional assurance of success. By prioritizing accuracy, using the right equipment, and applying comprehensive material knowledge, professionals can enhance the reliability and performance of their projects.