Are you having issues with your flow meter readings? Do you suspect that your flow meter may be inaccurate or not functioning properly? Don’t worry; in this guide, we will walk you through the process of how to calibrate a flow meter to ensure accurate readings.

Calibrating a flow meter is a crucial process to ensure accurate and reliable measurements in a variety of applications, ranging from industrial processes to scientific research. Flow meter calibration involves comparing the device’s measurements to a known standard, identifying any discrepancies, and making necessary adjustments to maintain precision. Proper calibration is essential for maintaining system efficiency, reducing errors, and ensuring compliance with industry regulations.

This guide outlines the steps and considerations needed to calibrate a practical flow meter.

What Are the Benefits of Flow Meter Calibration?

There are several benefits to regularly calibrating your flow meter, including the following:

- Accurate Measurements: By comparing the readings of your flow meter to a known standard, you can ensure that your device provides accurate measurements. This is crucial in industries where precise measurements are necessary for efficient operations and quality control.

- Optimized System Performance: As mentioned earlier, proper calibration helps maintain system efficiency by identifying any discrepancies or errors in the flow meter. You can optimize your system’s performance and minimize downtime due to faulty readings by making necessary adjustments.

- Compliance with Industry Regulations: Many industries have strict regulations on the accuracy and precision of flow meters. Regular calibration ensures that your system meets these standards and helps you avoid potential penalties or legal issues.

- Longer Lifespan of Equipment: A well-calibrated flow meter can last longer and require less frequent replacements or repairs. This is because calibration ensures that all components function correctly, reducing wear and tear on the equipment.

- Cost Savings: Regular calibration can save you money in the long run by optimizing system performance and prolonging equipment lifespan. It also helps prevent unnecessary maintenance costs and production losses due to inaccurate flow measurements.

What Will You Need?

To calibrate a flow meter, you will need the following equipment:

- Calibrators: These are devices used to generate a known flow rate for comparison with the reading of the flow meter being calibrated.

- Test Measures: These are instruments used to verify and record the flow meter readings during calibration.

- Adapters and Fittings: These are necessary for connecting the calibrator and test measures to the flow meter. Ensuring they are compatible with all components involved in the calibration process is essential.

- Cleaning Supplies: Before performing any calibration, cleaning the flow meter thoroughly is crucial to remove any debris or build-up that could affect its accuracy.

8 Easy Steps on How to Calibrate a Flow Meter

Step 1. Gather All Necessary Equipment:

Before starting the calibration process, ensure you have collected all the required tools and materials to perform the procedure efficiently and accurately. This includes the calibration device, reference flow standard, adapters, fittings, cleaning supplies, and any technical documentation related to the flow meter and calibration tools.

Verify that all equipment is properly working to avoid disruptions during the process. Organizing everything beforehand saves time and reduces the chances of errors, ensuring a smooth calibration.

Step 2: Prepare the Work Area

Ensure the work area is clean, well-lit, and free of any obstructions. A tidy and organized workspace minimizes the risk of contamination or damage to the equipment. Position the calibration device and flow meter on a stable surface and secure all components to prevent any unnecessary movement during the procedure. This step lays the foundation for precise and reliable calibration results.

Step 3: Conduct Preliminary Checks

Before beginning the calibration procedure, thoroughly inspect the flow meter and calibration device. Verify that all connections are secure and check for any visible signs of damage or wear that may affect accuracy.

Ensure that the equipment is compatible with the specific calibration requirements and that all necessary tools and reference materials are readily available. Conducting these preliminary checks helps identify potential issues early, preventing disruptions during the calibration process.

Step 4: Set Up Calibration Equipment

Before beginning the calibration process, it is crucial to set up and prepare the calibration equipment properly. This ensures accurate measurements and reduces the risk of errors during calibration.

First, ensure the flow meter is clean and free of debris or buildup. Use a soft cloth or brush to gently remove dirt or residue from the meter’s exterior and internal components. Additionally, ensure that the flow meter is in good working condition before calibrating.

Next, assemble all necessary equipment according to the manufacturer’s instructions. This may include specific adapters, hoses, and reference materials for your particular type of flow meter. Double-check that all connections are secure and that there are no leaks or obstructions that could affect the accuracy of your calibration.

Step 5: Begin the Calibration Process

Start the calibration by setting the flow meter to the specified flow rate according to the manufacturer’s guidelines. Use the reference standard to measure and compare the flow rates, ensuring that the output from the flow meter matches the expected values. Record any discrepancies and adjust the flow meter settings to align the readings accurately. Repeat this process at multiple flow rate points to verify consistency and precision across the meter’s range.

Step 6: Record and Evaluate Results

Once the flow meter has been calibrated at various flow rates, record all the results in a calibration certificate. This document should include the date of calibration, the reference standard used, the measured values at different flow rates, and any adjustments made during the calibration process.

To evaluate the results, compare them to previous calibration records and industry standards. Look for any significant deviations or inconsistencies that may indicate potential issues with the flow meter’s accuracy or performance. If necessary, repeat the calibration process to ensure accurate readings.

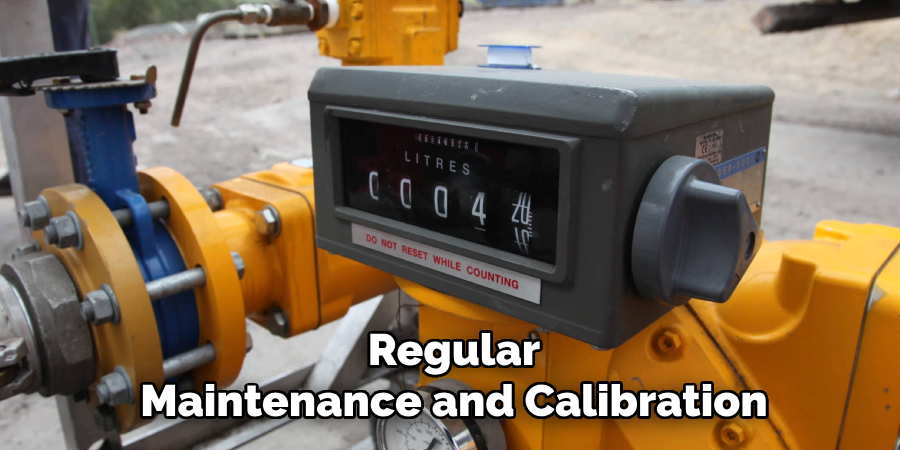

Step 7: Maintenance and Re-calibration

Proper maintenance and periodic recalibration are essential to ensure the flow meter delivers accurate and reliable measurements over time.

Maintenance activities should include regular inspection of the flow meter for wear and tear, cleaning any components prone to buildup or blockages, and verifying connections to ensure they remain secure and functional. It is also crucial to monitor the operating conditions, such as temperature and pressure, to ensure they stay within the manufacturer’s specifications.

Re-calibration intervals should be determined based on factors such as the flow meter’s application, usage frequency, and environmental conditions. High-demand environments or those with harsh conditions may require more frequent recalibration to maintain accuracy.

During re-calibration, validate the flow meter’s performance against updated reference standards and document the results thoroughly. Maintaining detailed calibration and maintenance records will facilitate future evaluations, help identify trends, and support compliance with industry regulations.

Step 8: Keep Track of Flow Meter Performance

In addition to regular maintenance and calibration, it is essential to keep track of the performance of your flow meter over time. This can help identify any potential issues or changes in accuracy that may require further attention.

One way to monitor the performance of your flow meter is by conducting periodic audits. These audits involve comparing the results from your flow meter with those from a secondary measurement device, such as a master meter or standard reference equipment. If there are significant discrepancies between the two measurements, it may indicate that your flow meter needs to be recalibrated or serviced.

By following these best practices and regularly monitoring the performance of your flow meter, you can ensure accurate and reliable measurement results.

5 Things You Should Avoid

- Skipping Regular Calibration Intervals

Avoid neglecting the routine calibration schedule recommended by the manufacturer. Missing these intervals can lead to inaccurate readings, reduced efficiency, and potential system failures.

- Using Improper Calibration Tools

Ensure that the equipment used for calibration is precise and complies with industry standards. Using incorrect or poorly maintained tools can result in inaccurate calibration and unreliable measurements.

- Ignoring Environmental Factors

Calibration performed under unsuitable conditions, such as extreme temperatures or high humidity, can affect the flow meter’s accuracy. Always ensure the environment is within the recommended operational parameters during calibration.

- Rushing the Calibration Process

Avoid rushing through the calibration procedure, as skipping steps or not following the proper sequence can compromise the accuracy of the results. Take the necessary time to perform each step thoroughly and correctly.

- Failing to Document Calibration Results

Always record the calibration details, including the date, tools, and results. Failing to document these can make tracking performance trends or verifying compliance with standards during audits is impossible.

Conclusion

How to calibrate a flow meter is a precise process that requires attention to detail, adherence to proper procedures, and thorough documentation.

By carefully following the outlined steps, from preparing the equipment to performing the calibration and recording the results, you can ensure the accuracy and reliability of the flow meter. Regular calibration not only supports compliance with industry standards but also helps maintain the efficiency and effectiveness of the systems relying on the flow meter’s performance.

Hopefully, this guide has provided you with a better understanding of the importance of flow meter calibration and how to carry it out effectively.