Welcome, fellow homeowners and do-it-yourselfers! Are you tired of worrying about your boiler’s performance? Are you constantly wondering if it’s working as efficiently as it should be? Well, fear not because, in this blog post, we will dive into the world of boilers and teach you how to check pressure on boiler like a pro. With winter upon us, having a properly functioning boiler is crucial to keep your home warm and cozy.

However, many people are intimidated by the thought of checking their boiler’s pressure, often leaving it up to professionals. But with our step-by-step guide and easy-to-follow instructions, you’ll feel confident in maintaining your boiler.

So grab a cup of hot cocoa and become a pro at checking your boiler’s pressure!

What Will You Need?

Before we get into the nitty-gritty of checking your boiler’s pressure, let’s first go over what you’ll need for this task:

- A pressure gauge (either digital or analog)

- A towel or cloth

- Safety goggles (optional but recommended)

Now that you have all the necessary tools, let’s move on to checking your boiler’s pressure.

What are the Benefits of Checking Your Boiler’s Pressure?

You may be wondering why it’s essential to check your boiler’s pressure in the first place. Well, here are a few reasons:

- Ensures Maximum Efficiency: If your boiler is not functioning at the correct pressure, it can lead to wasted energy and increased utility bills.

- Identifies Potential Issues: By regularly checking your boiler’s pressure, you can catch any issues before they become significant problems. This can save you time and money in the long run.

- Maintains Safety: High or low boiler pressure can be dangerous and lead to accidents if not addressed promptly. Regular checks help keep your boiler running safely.

Now that we understand the importance of checking your boiler’s pressure, let’s move on to the steps involved.

10 Easy Steps on How to Check Pressure on Boiler

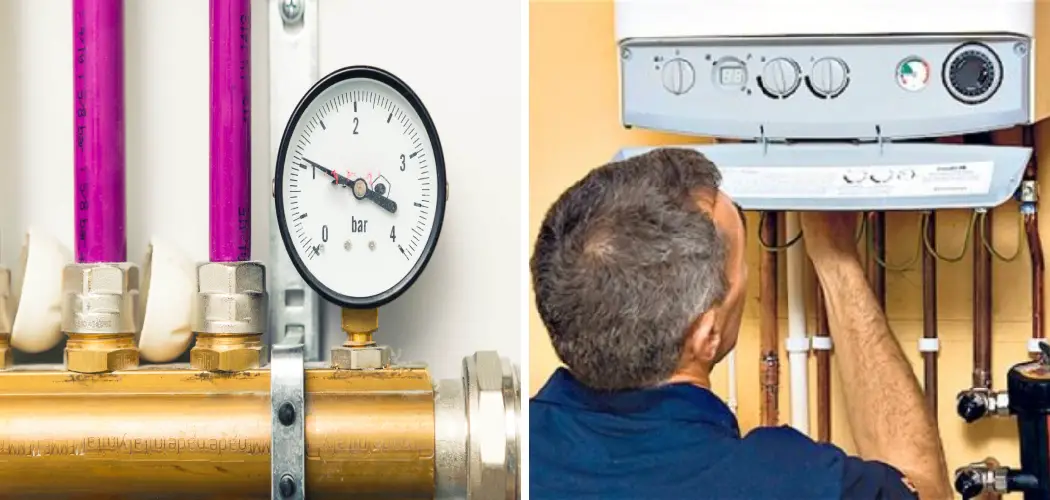

Step 1. Locate the Pressure Gauge

The pressure gauge is typically located on the front of the boiler, near the bottom. It may also be located on a separate control panel next to the boiler. The gauge will have numbers ranging from 0 to 30 or higher, indicating the pressure in bars.

Step 2. Check and Adjust the Pressure

To check the pressure on your boiler, simply look at the reading on the pressure gauge. If it is below 1 bar, you will need to add more water to increase the pressure. To do this, use a flathead screwdriver to turn the valve located under or near the boiler until it reaches 1 bar.

If it is above 2 bars, you must release some water by turning this valve counterclockwise until it reaches 1 bar. It’s essential to keep an eye on your boiler’s pressure regularly and adjust as needed to ensure proper functioning.

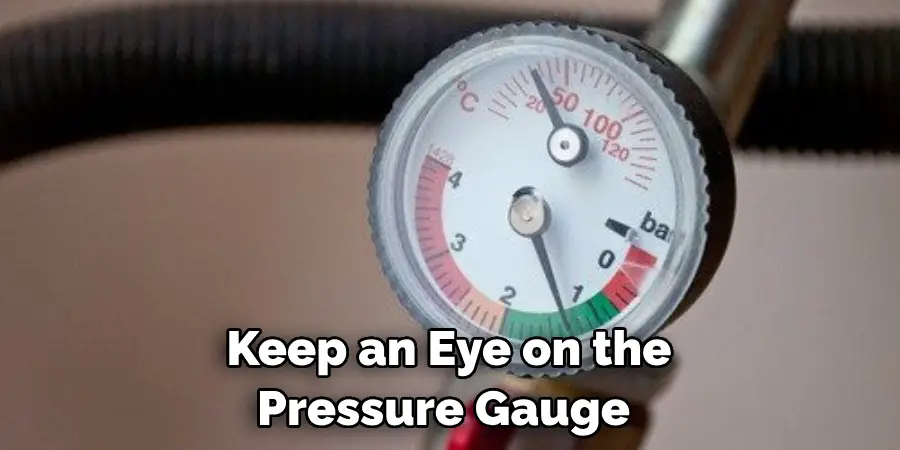

Step 3. Monitor the Gauge

After adjusting the pressure, continue to monitor the gauge for a few minutes to ensure that it remains stable. If the pressure continues to rise or fall drastically after your adjustments, this could indicate a more severe issue with your boiler that may require professional assistance.

Remember, safety should always be your top priority when dealing with boilers. Therefore, if you’re ever unsure or uncomfortable performing these checks yourself, don’t hesitate to hire a professional.

Step 4. Reset the System

Once you have checked and adjusted the pressure, it may be necessary to reset your boiler system. To do this, locate the reset button on your boiler – it’s usually a red or green button labeled “Reset”. Hold this button for a few seconds to reset your boiler system. You should hear a click, and the boiler should restart. Keep an eye on the pressure gauge to ensure it remains stable after the reset.

Step 5. Regular Maintenance

Remember that this is not a one-time job after successfully checking and adjusting your boiler pressure. Regular maintenance is critical to ensuring the longevity and efficiency of your boiler. Make it a habit to check your boiler’s pressure at least once a month.

This routine check-up will keep your boiler running optimally and alert you to potential issues before they escalate into costly repairs or replacements. You can enjoy a warm and cozy home throughout the cold winter months with proper care and regular pressure checks.

Step 6. Document Your Findings

After each pressure check, make a note of the boiler pressure readings and the date of the check. This will help you track any consistent changes in pressure over time and identify any patterns that may signal potential issues. Persistent low or high pressure is not normal and should be addressed by a professional.

By keeping detailed records, you’ll be well-prepared to discuss any concerns with a heating engineer if needed. Remember, proper record-keeping is crucial to maintaining your boiler and ensuring its longevity.

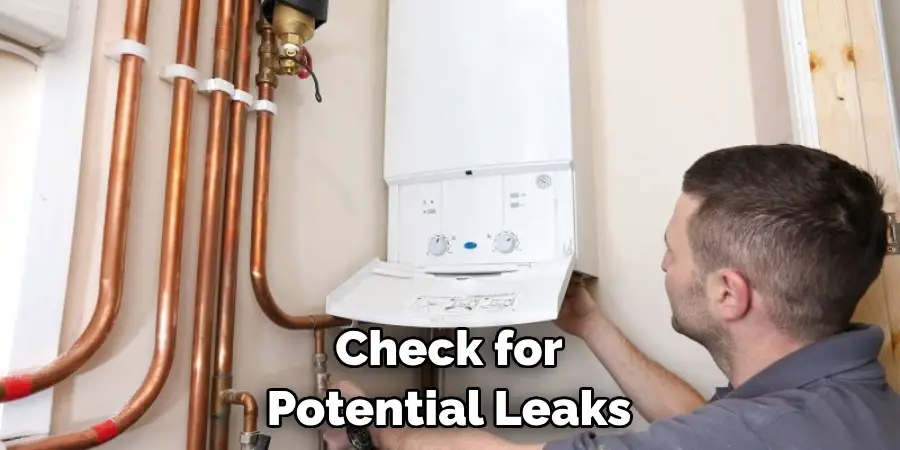

Step 7. Look for Leaks

Even if your boiler pressure seems to be stable, it’s always a good idea to check for potential leaks. Inspect the radiator valves, pipework, and the boiler itself for any signs of escaping water. If you find a leak, it’s essential to have it fixed by a registered engineer as soon as possible, as this could cause your boiler pressure to fluctuate. Remember, safety first – do not attempt to fix leaks on your own unless you’re a qualified professional.

Step 8. Consult the User Manual

If you’re still having trouble understanding how to check the pressure on your boiler or if you encounter an unfamiliar scenario, don’t hesitate to consult the user manual. Every boiler comes with a manual that provides detailed instructions on handling various maintenance tasks, troubleshooting common problems, and checking your boiler’s pressure.

The manual will also contain important safety information, so it’s wise to keep it in a handy place. If you’ve misplaced your manual, many manufacturers offer digital versions online.

Step 9. Seek Professional Assistance

If the pressure continues to fluctuate after going through these steps, it’s time to call in a professional. Engineers are trained to diagnose and repair boiler issues with safety as their top priority. They have the tools and knowledge to fix minor and major problems.

Remember, it’s always better to have your boiler inspected by a professional if you’re unsure about its condition. Regular servicing can also prevent issues from occurring in the first place and ensure your boiler is running at its most efficient level.

Step 10. Regular Servicing

The last but certainly not least step in maintaining your boiler’s pressure is to have it regularly serviced by a professional. Engineers check and adjust the pressure and inspect other parts of the boiler for potential issues.

Regular servicing ensures that your boiler performs optimally and efficiently, leading to energy savings in the long run. It also extends the life of your boiler, preventing premature breakdowns and costly replacements. Remember, the well-being of your boiler is ultimately linked to the comfort and safety of your home.

By following these steps and staying proactive in maintaining your boiler, you can ensure that it operates smoothly and efficiently, providing you with heat and hot water when needed most.

5 Additional Tips and Tricks

- Frequent Check-ups: Regularly checking your boiler pressure is essential. Inspecting it at least once a month is recommended to avoid any sudden boiler breakdowns.

- Refer to the Manual: Always refer to the boiler’s manual if unsure about any procedures. It contains specific instructions for your boiler model.

- Safety First: Never attempt to fix any severe issues on your own. If the pressure is too high or too low, call a professional.

- Pressure Release: If the pressure is too high, release tension by bleeding your radiators. However, ensure you know how to do this correctly to avoid causing damage.

- Preventative Measures: Regular servicing by a qualified engineer can prevent pressure issues. This will ensure that your boiler is safe, efficient, and reliable.

With these additional tips and tricks, you can avoid significant issues with your boiler’s pressure. Remember always to prioritize safety and consult a professional if needed.

6 Things You Should Avoid

- Ignoring Pressure Drops: A significant drop in boiler pressure could be a sign of a leak or malfunction. Ignoring this could lead to severe issues, including the complete failure of your boiler.

- Over Pressurizing: Avoid over-pressurizing your boiler as a quick fix for low-pressure issues. This could cause system overheating and other potential damages.

- Neglecting Annual Servicing: Skipping regular maintenance check-ups can lead to unnoticed pressure issues, resulting in sudden boiler breakdowns.

- DIY Fixes: Avoid trying to fix significant boiler issues independently unless you are a qualified engineer. Incorrect adjustments could lead to dangerous situations or costly repairs.

- Using Incompatible Parts: If parts need to be replaced, always use ones compatible with your boiler model. Using incompatible elements may create pressure problems and even void your warranty.

- Not Seeking Professional Help: If you are still trying to figure out what to do or have any concerns about your boiler’s pressure, always seek professional help. It’s better to be safe than sorry about your home heating system.

By avoiding these common mistakes, you can ensure the longevity and efficiency of your boiler. Remember always to prioritize safety and consult a professional if needed.

Which Pressure Sensor Used in Boiler?

Different boilers may use different pressure sensors, but the pressure relief valve is the most commonly used one. This safety device helps to regulate and release excess pressure in the boiler system.

Other types of sensors that may be used include gauge or differential pressure sensors, which measure and monitor the pressure levels within the boiler. It is essential to consult your boiler manual or a professional to determine the specific pressure sensor used in your boiler. This knowledge can help you understand the different readings and troubleshoot potential issues.

So, it is crucial to know how these sensors work and how to interpret their readings to maintain your boiler properly.

Why is the Boiler Losing Pressure?

There are many reasons why a boiler may be losing pressure, including:

- Leaking Pipes: A common cause of pressure loss is leaking pipes, which can lead to a drop in water pressure within the system.

- Faulty Pressure Relief Valve: If the pressure relief valve is defective, it may not function correctly and release too much or too little pressure.

- Air in the System: Air pockets within the system can cause a pressure drop, as they take up valuable space that should be filled with water.

- Expansion Tank Issues: The expansion tank helps to regulate the boiler pressure and prevent it from reaching dangerous levels. If there is an issue with this tank, it could lead to pressure problems.

- Incorrect Pressure Settings: If the boiler’s pressure settings are incorrect, it can cause pressure fluctuations, resulting in pressure loss.

If you notice your boiler is losing pressure, it is essential to promptly identify and address the underlying issue to prevent further damage. It is recommended to contact a professional for assistance if you need help with how to fix the problem.

Conclusion

In conclusion, by following these simple steps, you can quickly check the pressure on your boiler and ensure its optimal functioning. Remember to regularly monitor and adjust the pressure as needed to avoid any potential issues or malfunctions in the future. Additionally, keep in mind that maintaining a proper pressure level is crucial not only for your boiler’s performance but also for your safety. Neglecting this task could result in costly repairs or, even worse, accidents.

So take the time to check your boiler’s pressure regularly and thank yourself later for avoiding any avoidable complications. As we’ve seen, how to check pressure on boiler is a simple task and can easily be incorporated into your regular home maintenance routine. Don’t underestimate the importance of this small yet vital aspect of boiler care.

Now, it’s up to you to put these tips into practice and keep your boiler running smoothly for years to come.