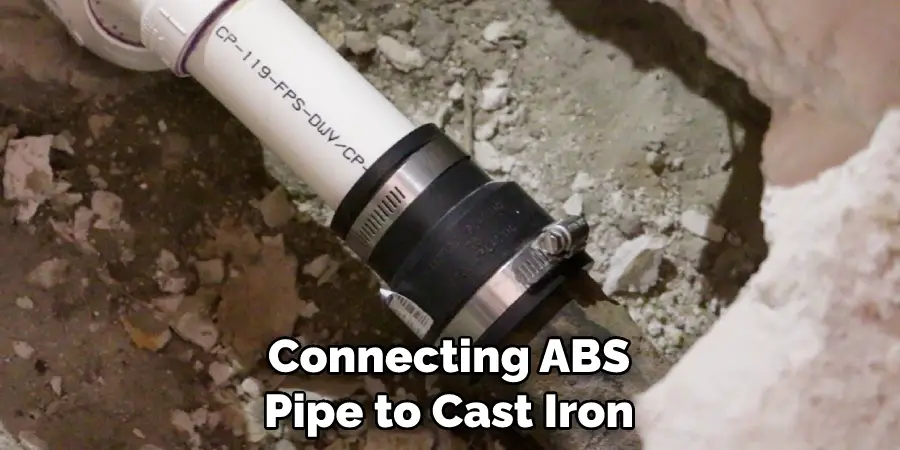

Do you need to connect an ABS pipe to a cast iron drain line? Perhaps you’re replacing one part of an existing drainage system and want to know the correct way to join ABS and cast iron pipes together. If so, this blog post is for you!

We’ll explore how different types of adhesive sealants can be used in the process and talk about the proper technique for getting it done right. Plus, we’ll go over why professional plumbers always take certain precautions when joining these two materials together. Read on for all the details of how to connect ABS pipe to cast iron safely and effectively!

What Type of Connector Is Used to Connect Cast Iron Pipe to Abs Pipe?

The most popular connector used to join ABS, and cast iron pipes is a Fernco fitting. This type of connector is designed to fit both materials and comes in various sizes to meet your needs. It also has an O-ring that helps it form a tight seal when tightened down with anchors or clamps.

While this type of connector is the most popular, it’s important to note that other types of connectors are available and may be more suitable for certain situations. Additionally, some plumbers also use compression couplings to join the two materials. This type of connector is used when the pipes being joined have different outer diameters.

10 Methods How to Connect Abs Pipe to Cast Iron

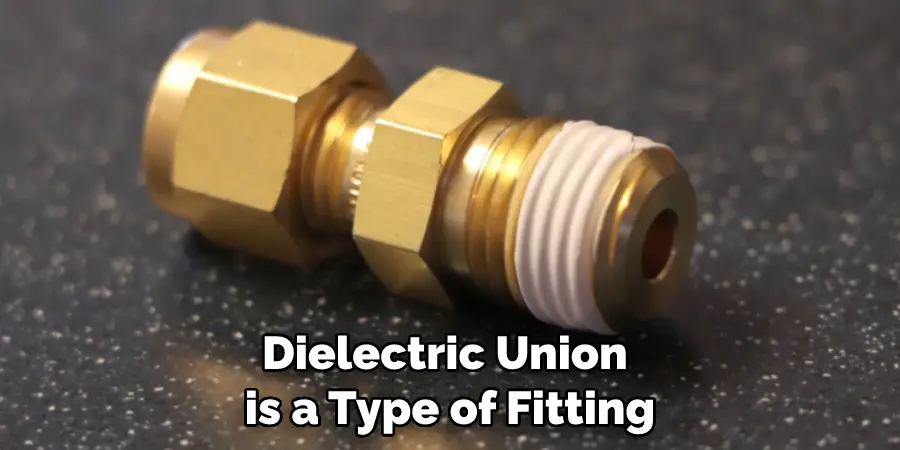

1. Use a Dielectric Union.

A dielectric union is a type of fitting that is used to connect two pieces of metal pipe together. Dielectric unions are available in a variety of sizes to fit different types of pipe. They consist of two halves that are threaded on the inside and screwed together. The two halves are separated by a rubber gasket that prevents corrosion from occurring between the two pieces of pipe.

2. Use a Threaded Adapter.

A threaded adapter is a type of fitting that is used to connect two pieces of pipe together. Threaded adapters are available in a variety of sizes to fit different types of pipe. They consist of a male thread on one end and a female thread on the other. The male thread is screwed into the female thread, which creates a tight seal.

3. Use a Slip Coupling.

A slip coupling is a type of fitting that is used to connect two pieces of pipe together. Slip couplings are available in a variety of sizes to fit different types of pipe. They consist of two halves that are held together by bolts or screws. The two halves are separated by a rubber gasket that prevents corrosion from occurring between the two pieces of pipe.

Slip couplings are an ideal solution for connecting pipes of different materials or sizes, such as copper and PVC. They also can be used to repair a broken pipe without having to replace the entire section. Slip couplings are relatively inexpensive and easy to install, making them a popular choice for many plumbing projects.

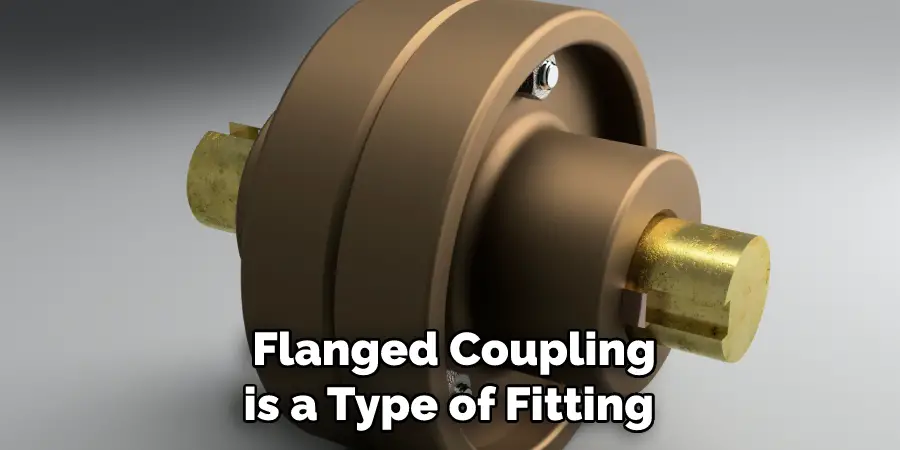

4. Use a Flanged Coupling.

A flanged coupling is a type of fitting that is used to connect two pieces of pipe together. Flanged couplings are available in a variety of sizes to fit different types of pipe. They consist of two halves that are held together by bolts or screws, and they have a raised lip or flange on one side that helps to prevent leaks.

Flanged couplings are usually made of metal, but they can also be made of plastic or other materials. They provide a strong connection between two pieces of pipe, but can be difficult to install in tight spaces. Additionally, they require specialized tools for installation. If correctly installed, flanged couplings provide a secure and reliable connection between pipes.

5. Use an Expansion Joint.

An expansion joint is a type of fitting that is used to connect two pieces of pipe together while allowing for expansion and contraction due to temperature changes. Expansion joints are available in a variety of sizes to fit different types of pipe.

They consist of two halves that are held together by bolts or screws, and they have accordion-like bellows in the middle that allows for expansion and contraction. Installing an expansion joint is a relatively easy job, but it should be done by a professional if you are unsure of how to install one properly. Doing so will help prevent any damage or leaks that could occur as a result of improper installation.

6. Check the Pipe Connections Regularly.

It’s important to regularly check the connections of your pipes to make sure that they are secure and tight. This will help prevent any leaks from occurring due to loose fittings or worn-out seals. If you notice any problems with the pipe connections, it’s important to get them repaired as soon as possible before they cause a more serious problem. Regular maintenance will also help extend the life of your pipes and keep them working properly for longer.

7. Insulate Your Pipes.

If you live in an area with cold winters, it’s important to insulate your pipes to help prevent them from freezing and bursting due to the low temperatures. You can purchase insulated pipe wraps or foam insulation sleeves that can be easily wrapped around the pipes for added protection against freezing. It’s also a good idea to install insulation in any unheated areas of your home, such as crawl spaces and attics, as these are prime places for frozen pipes during cold weather seasons.

8. Use Pipe Straps When Necessary.

Pipe straps are small metal straps that are used to secure two pieces of pipe together at points where they cross or intersect. They provide extra support and help to keep the pipes in place and prevent them from coming loose due to vibrations or other external forces. It’s important to use pipe straps whenever necessary since not doing so could lead to leaks or a broken pipe.

9. Repair Any Leaks Immediately.

Leaking pipes can cause a lot of damage if they are not fixed quickly, so it’s important to repair any leaks as soon as you notice them. Depending on the severity of the leak, you may need to call a professional plumber for assistance.

If the leak is minor, however, you may be able to fix it yourself using some basic tools and supplies found at your local hardware store. It’s important to address any problems with your pipes quickly in order to avoid further damage and costly repairs.

10. Be Careful When Working with Pipes.

Whenever you are working with pipes, it’s important to be extremely cautious in order to avoid any accidents or injuries. Wear protective clothing and eye protection when handling sharp tools, wear gloves when touching hot pipes, and always make sure that your work area is well-lit so that you can clearly see what you are doing. Following these safety precautions will help ensure that you stay safe while working on your plumbing system.

This concludes our list of 10 tips for maintaining your plumbing system. By following these guidelines, you can keep your pipes in good condition and help prevent any costly repairs or water damage due to faulty piping. Always remember to call a professional plumber if you come across any problems that are too big for you to handle on your own.

Things to Consider When Connecting ABS Pipe to Cast Iron

1. Use a Rubber Compression Gasket:

When connecting ABS pipe to cast iron, use a rubber compression gasket in between the two pipes to create a watertight seal. This type of gasket is made of rubber and helps to absorb vibration and energy from the pipe. The gasket should be sized correctly for your project, so make sure you measure carefully before purchasing one.

2. Connect With an Approved Mechanical Joint:

To ensure a secure connection between ABS pipe and cast iron, use an approved mechanical joint. A mechanical joint is designed to hold pipes together without relying on a sealant or glue; instead, it uses threads to create a strong bond between the two pipes.

Make sure that the mechanical joint you are using has been approved by your local building codes or other regulations in order to ensure that it will provide a safe connection that meets all safety standards.

3. Use High-Grade Plumbing Supplies:

When connecting ABS pipe to cast iron, it is important that you use high-grade plumbing supplies. Low-quality materials can lead to leaks and other problems down the line. Make sure to buy supplies from a reputable dealer that specializes in plumbing products.

Conclusion

Cast iron and ABS pipe are two of the most common piping materials used in residential applications. While they both have their advantages, they require different methods to connect them properly. With the right tools, connecting the abs pipe to cast iron is a relatively simple process.

Make sure you have the proper adapters and clean both surfaces before beginning. Once you’ve connected the pieces, test for leaks and make any necessary adjustments. With a little time and effort, you’ll be able to complete this project successfully. Thanks for reading our blog post on how to connect abs pipe to cast iron! We hope you found it helpful and informative.