When it comes to plumbing projects, soldering copper pipes has traditionally been the go-to method for creating strong, watertight connections. However, not everyone has the tools, experience, or confidence to work with a torch and solder.

Fortunately, there are alternative methods available that are simpler, safer, and just as effective, allowing anyone to connect copper pipes with ease. This guide will introduce you to solder-free solutions that save time and effort without compromising on quality.

Why Soldering May Not Always Be Practical

Soldering can be a challenging process, particularly for those who do not have prior experience or access to the necessary tools. The process requires a propane torch, solder, flux, and a steady hand to ensure a proper connection. Additionally, working with heat carries inherent risks, especially in tight or confined spaces where flammable materials might be present.

For some, the time required to practice and perfect soldering techniques may not be feasible for a quick repair or a small project. Furthermore, certain environments, such as locations with restricted ventilation, make the use of open flames unsafe or impractical. These limitations often lead homeowners and DIY enthusiasts to seek out alternative, solder-free methods for connecting copper pipes.

Benefits of Connecting Copper Pipes Without Soldering

Opting for solder-free methods to connect copper pipes offers several key advantages. First, these methods are much easier and quicker to execute, making them ideal for DIY enthusiasts or those working on smaller projects. Without the need for specialized tools like a propane torch or extensive preparation, homeowners can tackle repairs or installations with greater confidence.

Additionally, solder-free connections eliminate the risks associated with working with open flames, such as accidental burns or fire hazards, especially in confined or hard-to-reach areas. These methods are also more environmentally friendly, as they avoid the fumes and residues produced by traditional soldering techniques.

Furthermore, modern solder-free solutions provide reliable, durable connections that meet plumbing standards, ensuring long-lasting performance without sacrificing quality.

10 Methods How to Connect Copper Pipe without Soldering

1. Using Push-to-Connect Fittings

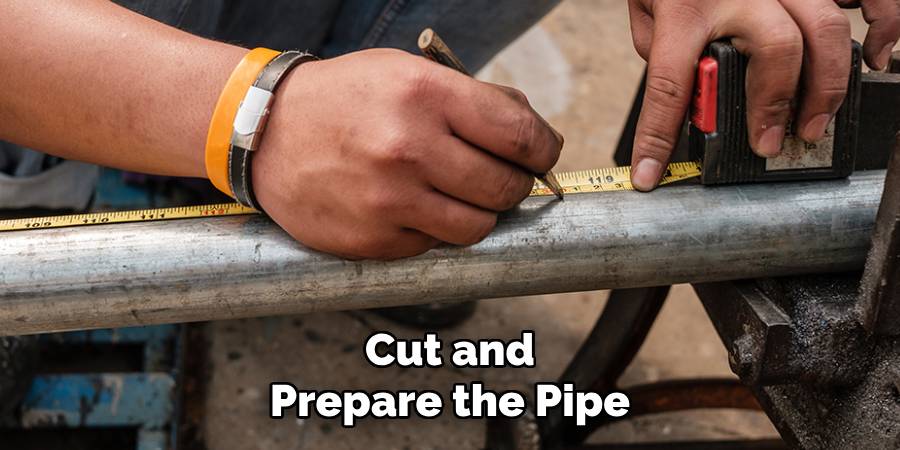

Push-to-connect fittings, also known as push-fit fittings, are among the easiest ways to connect copper pipes without soldering. These fittings have an internal mechanism that grips and seals the pipe securely when inserted. To use, simply cut the pipe cleanly, deburr the edges, and push it into the fitting until it locks in place. Push-to-connect fittings are ideal for quick repairs or when working in tight spaces. They’re available in various sizes and configurations, making them versatile for different plumbing needs.

2. Utilizing Compression Fittings

Compression fittings provide a watertight seal without the need for soldering. They consist of three main components: a compression nut, a compression ring (or ferrule), and the fitting body. To connect copper pipes using this method, slide the nut and ring onto the pipe, insert the pipe into the fitting body, and tighten the nut with a wrench. The compression ring creates a seal by deforming slightly as the nut tightens. This method is widely used for both plumbing and gas line applications.

3. Employing SharkBite Fittings

SharkBite fittings are a specific brand of push-to-connect fittings known for their reliability and ease of use. They feature a stainless steel grip ring and an O-ring seal, ensuring a secure and leak-free connection. These fittings work with copper, PEX, CPVC, and other types of pipes, making them versatile. Simply clean the pipe ends, mark the insertion depth, and push the pipe into the fitting until it reaches the marked depth. SharkBite fittings are particularly popular for their durability and reusability.

4. Using Press Fittings

Press fittings, also known as crimp fittings, use a mechanical tool to create a watertight seal. These fittings have a metal sleeve that compresses onto the pipe when the tool is applied. To use press fittings, cut and prepare the pipe, insert it into the fitting, and use a pressing tool to crimp the connection. Press fittings are often used in professional plumbing jobs due to their reliability and ability to handle high-pressure systems.

5. Applying Threaded Adapters

Threaded adapters are another effective method for connecting copper pipes without soldering. This approach involves using threaded fittings in combination with Teflon tape or pipe thread sealant. Simply wrap the threads of the fitting with Teflon tape, screw it into place, and tighten with a wrench. Threaded adapters are commonly used in situations where pipes need to be connected to appliances or other threaded fixtures.

6. Using Epoxy Adhesives

Epoxy adhesives can be used to bond copper pipes securely. These adhesives are specially formulated to withstand pressure and temperature variations in plumbing systems. To use, clean the pipe ends thoroughly, apply the epoxy adhesive to both surfaces, and press them together. Allow the adhesive to cure for the recommended time before turning on the water supply. This method is suitable for small repairs or when other fittings are unavailable.

7. Clamping with Rubber Couplings

Rubber couplings, often reinforced with metal clamps, are a flexible option for connecting copper pipes. These couplings are particularly useful for temporary fixes or connections in tight spaces. To install, slide the coupling over the pipe ends and secure it with the built-in clamps. Tighten the clamps using a screwdriver or wrench to create a watertight seal. Rubber couplings can accommodate slight misalignments and are often used in drainage systems.

8. Using Slip Couplings

Slip couplings are designed for quick and efficient pipe repairs. These fittings slide over the pipe ends and feature O-rings or gaskets that create a watertight seal. To use a slip coupling, cut out the damaged section of the pipe, deburr the edges, and slide the coupling into place. Some slip couplings also have an adjustable design, allowing for a perfect fit even in awkward locations.

9. Installing Flare Fittings

Flare fittings are commonly used in gas lines but can also be applied to copper water pipes. This method involves using a flaring tool to expand the pipe’s end into a cone shape. The flared end fits snugly into a corresponding fitting, and a nut is tightened to secure the connection. Flare fittings create a strong seal without the need for heat, making them ideal for high-pressure systems.

10. Employing Mechanical Grip Fittings

Mechanical grip fittings use a combination of rubber seals and metal grips to create a secure connection. These fittings are tightened using bolts or screws, compressing the rubber seal against the pipe for a watertight joint. Mechanical grip fittings are versatile and can be used in both permanent and temporary installations. They’re especially useful in industrial settings where quick assembly is required.

Maintenance and Upkeep

Proper maintenance of copper pipe connections is essential to ensure their longevity and functionality. Regardless of the method used to connect the pipes, regular inspections should be conducted to check for signs of wear, corrosion, or leaks. Clean the pipe surfaces periodically to prevent the buildup of debris or mineral deposits, which could compromise the integrity of the connections. If push-to-connect or SharkBite fittings are used, ensure they remain secure and free from any damage or loosening over time.

For threaded adapters, it’s important to periodically check the fittings for tightness and reapply Teflon tape or pipe thread sealant if necessary. When using rubber couplings or mechanical grip fittings, inspect the clamps and bolts to ensure they remain properly tightened and the seals are intact. Additionally, epoxy-based connections should be reviewed for cracks or deterioration, especially under extreme temperature or pressure conditions.

Common Mistakes to Avoid

When working with copper pipes and their connections, certain common mistakes can compromise the integrity of your plumbing system. Here are some pitfalls to watch out for and how to avoid them:

Improper Pipe Preparation

Failing to properly clean and deburr pipe ends before making a connection can lead to leaks or weakened seals. Always ensure that the ends of the pipes are clean, smooth, and free of debris or oxidation.

Using the Wrong Fittings

Selecting the incorrect fitting type for your specific application can result in poor performance or even system failure. Be sure to match the fitting material and design to the type of pipe and intended use.

Overtightening Connections

Over-tightening threaded adapters, clamps, or mechanical grip fittings can damage the pipes or crush seals, leading to leaks. Tighten connections securely but avoid applying excessive force that could compromise the integrity of the components.

Neglecting to Measure Correctly

Incorrect measurements can lead to gaps, misalignments, or the need for unnecessary adjustments. Always measure and mark pipe lengths accurately before cutting or connecting.

Skipping Leak Tests

After completing a connection, failing to conduct a leak test is a critical oversight. Always test for leaks by applying pressure or turning on the water supply gradually, ensuring the connections hold properly before full usage.

Conclusion

Working with copper pipes requires careful preparation, the right tools, and a clear understanding of the various connection methods available. Whether using traditional techniques like soldering or modern solutions such as push-to-connect fittings, each method has its own advantages and best-use scenarios.

By avoiding common mistakes, performing regular maintenance, and selecting the appropriate connection methods, you can ensure a durable, efficient plumbing system. Thanks for reading, and we hope this has given you some inspiration on how to connect copper pipe without soldering!