If you’re looking for a simple and effective solution to those pesky misaligned PVC pipes, look no further! In this blog post, we’ll be exploring the various methods for aligning and connecting two pieces of PVC pipe in order to create a robust sealed connection.

Whether you’re looking for a reliable method to tackle those important home renovations or just trying to understand how the pros connect their piping projects together – this article is guaranteed to provide valuable insights and tips on how to connect misaligned PVC pipe. So don’t waste any more time, grab some tools, and let’s get started on fixing those misaligned pipes!

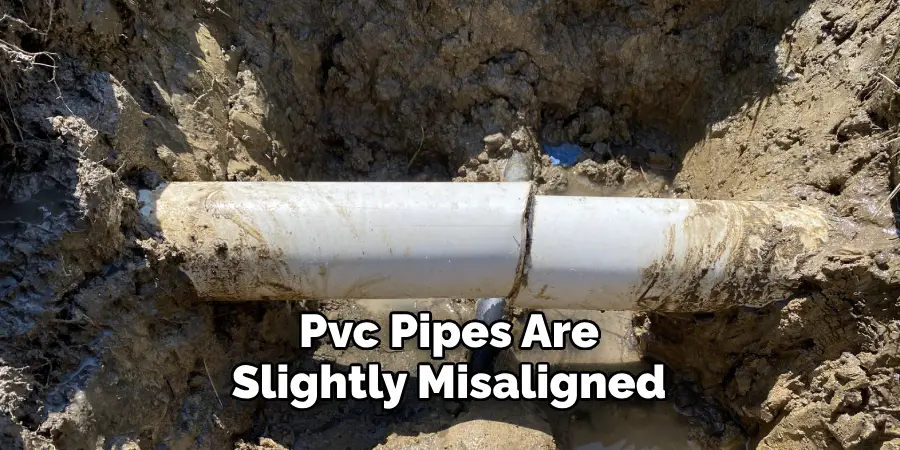

What Causes Misaligned PVC Pipes?

Before we dive into the solutions, it’s important to understand what causes PVC pipes to become misaligned in the first place. There are a few factors that can contribute to this issue such as poor installation, ground shifting, or even extreme weather conditions.

It’s also possible for pipes to become misaligned over time due to wear and tear. Whatever the reason may be, fortunately, there are simple solutions for fixing misaligned PVC pipes.

10 Best Methods on How to Connect Misaligned PVC Pipe

1. Using a Flexible Connector:

A flexible connector is a great option when dealing with misaligned pipes. These connectors are made from durable rubber and can easily bend and flex to fit any angle. Simply slip the connector onto each pipe end and tighten the clamps for a secure connection. This method is perfect for tight spaces or when the pipes are at odd angles.

2. Heat and Bend Method:

If your PVC pipes are slightly misaligned, you can use heat to bend them into place. Use a heat gun or even a hairdryer to warm up the area where the pipe needs to be bent. Once it’s pliable, carefully bend it into position and hold it until it cools and sets in its new shape. This may take some practice but can be an effective solution for minor misalignments.

3. Cutting and Rejoining:

For more severe misalignments, it may be necessary to cut the pipes and rejoin them with a coupling or repair sleeve. Use a hacksaw or PVC pipe cutter to make clean cuts on either side of the misaligned area. Then, use PVC primer and cement to secure the new joint in place. This method is more time-consuming but will provide a strong and stable connection.

4. Using a PVC Union:

A PVC union is a handy fitting that allows you to disconnect and reconnect pipes easily. This is a great option for future maintenance or repairs, as it eliminates the need to cut and rejoin pipes each time. Simply use PVC cement to attach the union to one end of the misaligned pipe, then connect the other end as normal.

5. Slip Joint Coupling:

Similar to a PVC union, a slip joint coupling can also be used for easy disconnection and reconnection of pipes. This fitting has two ends that slide together and are secured with clamps or screws. It’s important to note that the inner diameter of the coupling must match the outer diameter of the pipe for a proper fit.

6. Using a Rubber Coupling:

A rubber coupling is another option for connecting misaligned PVC pipes. It has two ends that fit onto the pipes, and the middle section is made from flexible rubber to accommodate any angles or offsets. These couplings are easy to install and provide a strong connection that can withstand pressure and movement.

7. Adding Extra Support with Brackets:

Sometimes pipes become misaligned due to a lack of support, especially in longer runs. In these cases, it may be necessary to add additional support with brackets or hangers. These can help hold the pipes in place and prevent them from shifting or sagging over time. Just be sure to use brackets specifically designed for PVC pipes.

8. Using a Pipe Bender:

If you have a pipe bender or access to one, this can also be an effective method for fixing misaligned pipes. Simply follow the instructions on the bender and carefully shape the pipe into the desired angle. This may take some practice but is a great solution for larger projects that require multiple bent pipes.

9. Create a Custom Fitting:

For unique angles or offsets, you can create a custom fitting using a PVC pipe and a heat gun. Cut the desired length of the pipe and heat it until it’s pliable enough to bend to the desired angle. Once cooled, use PVC cement to secure the joint in place. This is a great option for tight spaces or when other fittings won’t work.

10. Seek Professional Help:

If all else fails and the misalignment is severe or complex, it’s always best to seek professional help. Plumbers or contractors have the knowledge, tools, and experience to properly fix misaligned PVC pipes and ensure a long-lasting connection. Don’t hesitate to call in the experts if you’re unsure about tackling the project yourself.

Following these methods should help you successfully connect misaligned PVC pipes and achieve a strong and sealed connection. Remember to always take necessary safety precautions, such as wearing gloves and eye protection, when working with PVC pipes and tools. Good luck with your piping project! Happy connecting!

Additional Tips and Tricks to Connect Misaligned Pvc Pipe

1. Before connecting misaligned PVC pipes, it is important to sand down the ends of the pipes. This will help remove any burrs or jagged edges that may prevent a proper connection. Use sandpaper or a file to smooth out the ends.

2. Apply PVC primer and cement on both ends of the pipes before connecting them. This will not only help soften the plastic for better bonding but also clean any dirt or debris from the pipe surface. Allow the primer to dry completely before applying cement.

3. When connecting pipes with a slight misalignment, use flexible couplings or rubber sleeves. These allow for some flexibility and movement, making it easier to connect pipes that are not perfectly aligned. Be sure to use clamps or hose clamps to secure the coupling in place.

4. If you are connecting pipes with a significant misalignment, consider using a PVC pipe union. This fitting has two pieces that can be connected and tightened together, allowing for a larger degree of movement and flexibility. It is important to note that unions may not be suitable for high-pressure applications.

5. In cases where the misalignment is caused by a bend or curve in the pipe, use a heat gun to soften and mold the PVC into the desired shape before connecting it with another pipe. This method requires careful handling as overheating can cause the pipe to melt or deform.

6. If the misalignment is too severe or cannot be corrected with the above methods, you may need to use a PVC pipe bender. This tool can heat and bend the pipe to the desired angle or curve without causing any damage. However, it may not be cost-effective for one-time use.

7. Always check for any leaks after connecting PVC pipes. Use a leak detector or sprinkle some soapy water onto the joints and look for bubbles to ensure a tight and secure connection. If leaks are found, disassemble and repeat the connection process using proper methods.

8. When joining PVC pipes with different diameters, use a reducer or increaser fitting to ensure a proper fit. Make sure to check the compatibility of these fittings with your specific pipe material before purchasing.

9. If you are connecting pipes that will be buried underground or exposed to extreme weather, it is recommended to use PVC glue with a higher bonding strength. This will provide extra durability and prevent any future leaks.

10. It is important to always follow the manufacturer’s instructions when using PVC primer and cement. Improper use can result in weak connections or even cause damage to the pipes over time.

Following these additional tips and tricks can help ensure a strong and sturdy connection for misaligned PVC pipes. Remember to always take safety precautions, wear protective gear, and handle the pipes carefully to avoid any accidents or injuries.

So, it is important to do thorough research and choose the best method before attempting to connect misaligned PVC pipes. With the right tools and techniques, you can easily achieve a secure and long-lasting connection without any hassle. Happy piping!

Things You Should Consider to Connect Misaligned PVC Pipe

1. Type of Pvc Pipe:

Before connecting misaligned PVC pipes, it is essential to determine the type of PVC pipe you are working with. There are different types of PVC pipes available in the market, such as Schedule 40, schedule 80, and CPVC. Each type has its unique features and uses. Hence, make sure that you know the exact type of PVC pipe you need to connect.

2. Proper Measurements:

Proper measurements are crucial when connecting Misaligned PVC pipes. You need to ensure that you measure the exact length of the pipes and the angle at which they are misaligned. This will help you determine the correct fittings and connectors needed to align the pipes correctly.

3. Cleaning the Pipes:

Before connecting the pipes, it is essential to clean them thoroughly. Any dirt, debris, or grease on the surface of the pipes can affect the adhesion of the connectors and fittings. Use a clean cloth and PVC solvent cleaner to remove any residue from the pipes before connecting them. This will help ensure a strong and secure connection.

4. Dry Fitting:

Dry fitting is an essential step in connecting misaligned PVC pipes. It involves connecting the pipes without any adhesive to check if they align perfectly. If the pipes are not aligned correctly, you can make necessary adjustments before permanently securing them with adhesive. This step will save you from having to redo the entire process if there are any issues with alignment.

5. Choosing the Right Adhesive:

Choosing the right adhesive is crucial for a strong and durable connection between misaligned PVC pipes. PVC glue or solvent cement is the most commonly used adhesive for connecting PVC pipes. Make sure to use an appropriate type of adhesive for your specific type of PVC pipe. Read the instructions carefully and apply the adhesive as directed to ensure a proper bond.

6. Applying Adhesive:

Once you have chosen the right adhesive, apply it to both ends of the pipes and fittings that need to be connected. Make sure to evenly coat the surfaces with adhesive to ensure a secure connection. Avoid using too much adhesive as it can drip and create messy joints. While applying the adhesive, make sure to rotate and push the pipes together to ensure a tight fit.

7. Allow Time for Adhesive to Dry:

After connecting misaligned PVC pipes, it is crucial to allow enough time for the adhesive to dry completely. This can take anywhere from 30 minutes to an hour depending on the type of adhesive used. Avoid handling or using any force on the connected pipes until the adhesive has fully cured. This will help ensure that the connection is strong and durable.

Following these considerations will help you successfully connect misaligned PVC pipes and ensure a strong and durable connection. Remember to always take the necessary safety precautions when working with any type of adhesive, and consult a professional if needed. With the right tools and techniques, connecting misaligned PVC pipes can be done easily and efficiently. So go ahead and fix those uneven pipes without any worries! Happy connecting!

Conclusion

Connecting misaligned PVC pipes is simpler than you think. With the right materials, tools, and courage to attempt the job, anyone can learn how to do it properly. Be sure to measure correctly before cutting and use a miter saw for an accurate angle cut. Assemble everything together with glue and primer on the pipes prior to connecting them at both ends.

If any of these steps seem too intimidating for you, call a family member or friend who has experience working with plumbing to help you out. And always use caution when working around electricity! By following these steps and arming yourself with knowledge, you will be on your way to soaking in a warm bath from properly installed pipes connected by your own hands–yes, learning how to connect misaligned PVC pipe isn’t as hard as you may think!