Connecting PVC pipe without threads is a common practice in plumbing and construction, ensuring a strong and reliable bond between fittings. Unlike threaded connections, which can sometimes weaken over time, solvent welding or using PVC adhesives creates a seamless joint that can withstand pressure and prevent leaks.

This guide will explore how to connect pvc pipe without threads, making it easier for both DIY enthusiasts and seasoned professionals to achieve sturdy installations. Whether you’re working on a home project or a larger construction task, understanding how to connect PVC pipes properly is crucial for long-lasting results.

The Versatility and Common Uses of PVC Pipes

PVC pipes are renowned for their versatility and are widely used across various industries. One of the most common applications is in plumbing systems, catering to both residential and commercial properties. Their resistance to corrosion and chemical damage makes them an ideal choice for transporting water, sewage, and other liquids.

Additionally, PVC pipes are frequently utilised in irrigation systems for agriculture, ensuring efficient water delivery to crops. Beyond plumbing and irrigation, these pipes are also employed in electrical conduits, drainage systems, and even in the construction of furniture and signage. Their lightweight nature, coupled with durability and affordability, has solidified PVC pipes as a preferred option for countless applications.

Types of PVC Pipes

PVC pipes come in various types, each designed for specific applications and environments. The most common types include:

- Schedule 40 PVC Pipe: This type is widely used in residential plumbing and drainage applications. Its moderate thickness provides a good balance between durability and flexibility, making it suitable for typical indoor and outdoor use.

- Schedule 80 PVC Pipe: Thicker and stronger than Schedule 40, Schedule 80 PVC pipe is ideal for more demanding applications where higher pressure resistance is required. It is often used in commercial plumbing and industrial settings.

- PVC Agricultural Pipe: Specifically designed for agricultural use, this type of pipe is tailored to withstand the demands of irrigation systems and water transportation in farming. It typically features a lower pressure rating, as effective flow is more critical than high pressure in these applications.

- PVC DWV Pipe: Drainage, Waste, and Vent (DWV) PVC pipes are designed for drainage systems. They are often used for waste water and sewage systems, featuring larger diameters to accommodate heavy flow.

- PVC Pressure Pipe: This type of pipe is designed to carry pressurized water and other liquids. It is commonly used in residential water supply systems and in municipal water lines.

10 Methods How to Connect Pvc Pipe without Threads

1. Using PVC Cement

PVC cement is the most widely used method for connecting PVC pipes without threads. It creates a permanent bond by chemically softening the plastic surfaces of the pipes and fittings, allowing them to fuse together. This method is quick, easy, and provides a watertight seal.

To use PVC cement, start by cutting the PVC pipes to the desired length using a PVC cutter or hacksaw. Next, clean the ends of the pipe and the inside of the fitting with a PVC cleaner or primer, which helps remove any dirt, grease, or residue that might interfere with the bonding process. Apply the PVC cement evenly to both the outside of the pipe and the inside of the fitting. Immediately push the pipe into the fitting and hold it in place for a few seconds to ensure a secure bond.

2. Using PVC Primer and Cement

For a stronger and more reliable connection, using PVC primer in conjunction with PVC cement is highly recommended. The primer softens the surface of the PVC, allowing the cement to penetrate and create a stronger bond.

First, apply PVC primer to the outside of the pipe and the inside of the fitting. Allow the primer to dry for about 10-15 seconds. Then, apply a generous layer of PVC cement to both the pipe and the fitting. Quickly push the pipe into the fitting, twisting slightly to ensure an even distribution of the cement. Hold the joint in place for about 30 seconds.

3. Using Push-Fit Connectors

Push-fit connectors are a convenient and tool-free method for joining PVC pipes without threads. These connectors use a series of O-rings and teeth to securely hold the pipe in place. They are great for quick installations, repairs, and systems that might need to be modified or expanded later.

To use push-fit connectors, cut the PVC pipe to the required length and deburr the edges to ensure a smooth insertion. Simply push the pipe into the connector until it hits the internal stop. The O-rings inside the connector create a watertight seal, while the internal teeth grip the pipe securely. Push-fit connectors are designed to work without glue, making them ideal for temporary setups or areas where future maintenance is expected.

4. Using Compression Fittings

Compression fittings are another reliable way to connect PVC pipes without threads. These fittings work by compressing a rubber gasket around the pipe as you tighten a nut, creating a secure and watertight seal.

To use a compression fitting, slide the compression nut and gasket onto the end of the PVC pipe. Insert the pipe into the fitting and tighten the compression nut by hand or with a wrench. As you tighten the nut, the gasket compresses around the pipe, sealing it tightly. This method is non-permanent and allows for easy disassembly, making it suitable for systems that may require future adjustments.

5. Using Solvent Welding

Solvent welding is a process similar to using PVC cement, but it involves a slightly different chemical reaction. The solvent softens the surface of the PVC pipes, allowing them to fuse together without any glue or mechanical fastening.

To solvent weld PVC pipes, clean the pipe ends and fittings with a solvent cleaner. Apply the solvent welding solution to both the pipe and fitting, then push them together. Hold the joint for a few seconds to ensure a firm bond. Once cured, solvent welding provides a permanent, leak-free connection that can withstand high pressures.

6. Using Heat Fusion

Heat fusion is an advanced technique that involves heating the ends of the PVC pipes and fittings to soften them, then pressing them together to fuse them into a single piece. This method is commonly used for industrial applications but can be applied in residential settings as well.

To use heat fusion, you’ll need a heat fusion machine or a specialized heating tool designed for PVC. Heat the ends of the pipe and fitting until they become soft and pliable. Press the heated ends together and hold them in place until the plastic cools and hardens, creating a solid, seamless bond.

7. Using Rubber Couplings with Hose Clamps

Rubber couplings with hose clamps provide a flexible and secure way to join PVC pipes without using glue or solvent. These couplings are especially useful for connecting pipes of different sizes or materials.

To use this method, place the rubber coupling over the ends of the PVC pipes you wish to connect. Tighten the hose clamps around the coupling using a screwdriver or wrench. The rubber coupling creates a tight seal around the pipe, and the hose clamps hold everything securely in place. This method is excellent for outdoor or underground installations, where the flexibility of the coupling can accommodate ground movement.

8. Using PVC Compression Couplings

PVC compression couplings are similar to compression fittings but designed specifically for joining two lengths of PVC pipe. These couplings feature a rubber gasket inside that compresses around the pipes to form a watertight seal.

To install a PVC compression coupling, simply insert the pipe ends into the coupling and tighten the nuts on either side. The internal gasket compresses around the pipes, forming a strong, watertight connection. PVC compression couplings are ideal for repair work, as they can be installed without disassembling the entire pipe system.

9. Using Slip Couplings

Slip couplings are designed to allow slight movement within the connection, which can be helpful in systems where expansion, contraction, or alignment issues are a concern. These couplings work by sliding over the PVC pipe and creating a tight fit without the need for glue or threads.

To use a slip coupling, cut the PVC pipes to the appropriate length and clean the ends. Insert the pipe ends into the slip coupling and position them as needed. Tighten the coupling, if necessary, depending on the design.

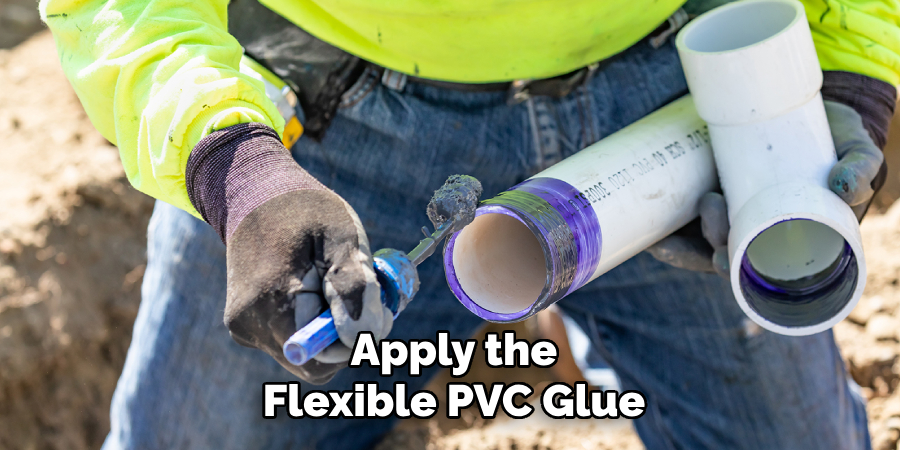

10. Using Flexible PVC Pipe and Glue

Flexible PVC pipe, also known as “flex pipe,” can be connected to rigid PVC using special flexible PVC glue. This type of connection is beneficial in situations where slight movements or bends in the pipe are necessary.

To connect flexible PVC pipe to rigid PVC, clean both pipe ends with a primer or cleaner. Apply the flexible PVC glue to both the rigid and flexible pipe ends. Insert the flexible pipe into the rigid PVC fitting or coupling and hold it in place for a few seconds.

Conclusion

Connecting PVC pipes without threads is a straightforward process once you understand the variety of methods available. Whether you’re using PVC cement, push-fit connectors, or heat fusion, there’s a solution to fit every application. Thanks for reading, and we hope this has given you some inspiration on how to connect pvc pipe without threads!