Connecting PVC (Polyvinyl Chloride) to a copper drain pipe may seem like a challenging task, but with the right techniques and materials, it can be done effectively. Whether you’re replacing a section of a drain pipe or completing a plumbing project, understanding how to connect PVC to a copper drain pipe is essential for a leak-free and secure joint.

The transition between these two different materials requires specific fittings and proper installation methods to ensure a reliable connection. In this article, we will explore the step-by-step process of how to connect pvc to copper drain pipe, providing you with valuable tips and instructions to help you successfully complete your plumbing project.

Importance of Proper Pipe Connections for Effective Drainage Systems

When creating a drainage system, proper pipe connections are essential for effective operation and to avoid costly repairs down the line. Connecting PVC pipes to copper drain pipes presents a unique set of challenges due to the different properties of each material.

To ensure that your drainage system will function smoothly, it’s important that you take the time to properly connect PVC pipes to copper drain pipes.

One key factor in making an optimal connection is ensuring that both the PVC and copper pipe ends are cut cleanly and squarely with no jagged edges or burrs. This helps provide a snug fit when connecting them together, which reduces chances of leakage. It’s also critical that you use high-quality sealants that can withstand any fluctuations in temperature or pressure.

Additionally, it’s essential that you invest in quality materials to ensure a secure connection between the two different types of pipe. Failing to do so could result in leakage and other costly repairs further down the line.

When connecting PVC pipes to copper drain pipes, it’s important to take your time and follow proper procedures. Doing so will help you create an effective drainage system that will provide years of reliable service with minimal maintenance costs.

If done improperly, however, you could be faced with major repair bills due to leaking and other issues caused by improper connections. So make sure that you take time when making these connections and use high-quality materials for best results!

Understanding the Characteristics and Differences between Pvc and Copper Pipes

PVC and copper pipes are two of the most popular types of piping used in plumbing today. PVC (polyvinyl chloride) is a thermoplastic polymer that is widely used for making rigid pipe, tubing, and fittings due to its durability, low cost, and resistance to corrosion.

Copper on the other hand has been around since ancient times and is still highly valued for its malleability, ductility and excellent resistance to corrosion. As such it’s an ideal choice for hot water lines that require long runs through various building materials.

The main differences between the two types of pipes lie in their physical characteristics. PVC is lighter than copper, making it easier to install with less labor demands. It’s also more flexible, so it’s easier to maneuver around tight spaces and corners. Copper is more durable than PVC, meaning that it won’t crack or break easily as temperatures vary.

Additionally, copper has a much lower coefficient of thermal expansion (CTE) which means that the pipe will expand slower when heated and return to its original size quicker upon cooling. Finally, copper offers greater resistance to fire compared to PVC so should provide better protection in the event of a localized fire outbreak.

Ultimately, both types of piping have their own unique advantages and disadvantages that you should consider when deciding which type to use for your plumbing project. By understanding these characteristics you can ensure that you are making an informed decision about what type of pipe best suits your needs.

Checking for Compatibility in Terms of Size, Fittings, and Application

The compatibility of PVC pipe and copper drain pipe based on size, fittings, and application should always be checked before attempting to connect them. When it comes to size, the diameter of the PVC and copper pipes should match as closely as possible. Fittings must also be taken into consideration; for example, a copper fitting cannot be used with a PVC pipe or vice versa.

Additionally, one must make sure that the type of application they are trying to undertake is suitable for both types of pipe; some applications may require specific materials that could limit your options in terms of what you can use.

Ultimately, when connecting PVC pipe to copper drain pipe, you want to make sure that all aspects from size to fittings and application are compatible. Taking the time to do the necessary research will help ensure that you are able to successfully connect these two materials.

To summarize, verifying compatibility between PVC pipe and copper drain pipe requires consideration of size, fittings, and application. It is important to take the time to do the research in order to make sure all of your materials are compatible and suitable for connecting these two materials. Taking the extra time to make sure everything is compatible will help you achieve a successful connection.

10 Methods How to Connect PVC to Copper Drain Pipe

1. Transition Fittings:

One of the most common methods to connect PVC to a copper drain pipe is by using transition fittings. These fittings are specifically designed to bridge the gap between the different materials. Transition fittings can be found in various shapes, such as couplings, adapters, and reducers.

Follow the manufacturer’s instructions for proper installation, ensuring a tight and secure connection between the PVC and copper pipes.

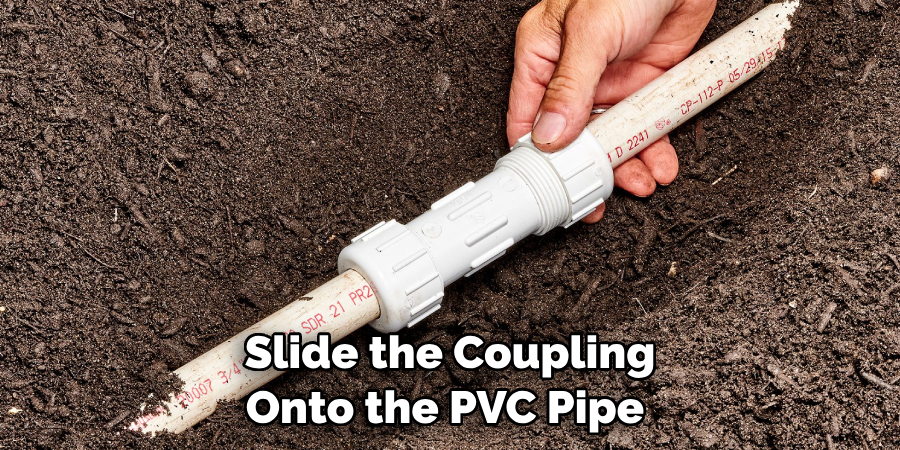

2. Compression Couplings:

Compression couplings are another reliable option for connecting PVC to a copper drain pipe. These couplings feature a compression nut and a rubber gasket that create a watertight seal when tightened.

To use a compression coupling, slide the nut onto the PVC pipe, insert the PVC pipe into the copper pipe, and slide the nut over the joint. Tighten the nut using an adjustable wrench until the coupling is securely in place.

3. Solvent Welding:

Solvent welding, also known as solvent cementing, is a popular method for joining PVC pipes. Although it is not a direct connection to copper, it can be used to connect PVC pipes to create a smooth transition from the copper drain pipe.

To solvent weld PVC to copper, use a transition fitting to connect the PVC pipe to the fitting, and then use a solvent cement designed for PVC to create a secure bond between the fitting and the PVC pipe. Follow the manufacturer’s instructions for proper application and curing time.

4. Push-Fit Connections:

Push-fit connections offer a convenient and efficient method to connect PVC to a copper drain pipe. These fittings feature a rubber O-ring that provides a tight seal when the pipe is inserted into the fitting. To connect PVC to copper using push-fit connections, simply slide the fitting onto the PVC pipe, insert the pipe into the copper pipe, and ensure that the fitting is fully inserted and seated securely.

5. PVC Adhesive:

Another option for connecting PVC to a copper drain pipe is by using PVC adhesive. This method involves applying a PVC adhesive or cement to the end of the PVC pipe and inserting it into a copper fitting or transition fitting.

The adhesive creates a strong bond between the PVC and the fitting, ensuring a secure connection. Follow the manufacturer’s instructions for the proper application and curing time of the PVC adhesive.

6. Rubber Couplings:

Rubber couplings, also known as fernco couplings, can be used to connect PVC to a copper drain pipe. These flexible couplings feature stainless steel clamps and a rubber sleeve that creates a watertight seal. To connect PVC to copper using a rubber coupling, slide the coupling onto the PVC pipe, insert the pipe into the copper pipe, and tighten the clamps using a screwdriver or socket wrench.

7. Compression Adapters:

Compression adapters provide a versatile solution for connecting PVC to a copper drain pipe. These adapters have a compression nut on one end and a female threaded connection on the other.

To use a compression adapter, slide the nut onto the PVC pipe, insert the pipe into the copper pipe, and tighten the nut onto the female threaded connection using an adjustable wrench. This creates a secure and leak-free connection.

8. SharkBite Fittings:

SharkBite fittings are a popular choice for connecting various types of pipes, including PVC and copper. These push-to-connect fittings feature a unique design that allows for quick and easy installation without the need for soldering or adhesive. To connect PVC to copper using SharkBite fittings, simply push the fitting onto the PVC and copper pipes until they are fully inserted and seated securely.

9. Expansion Couplings:

Expansion couplings are designed to accommodate the different expansion and contraction rates of PVC and copper pipes. These couplings consist of two halves connected by a rubber gasket that expands and contracts with temperature changes.

To connect PVC to a copper drain pipe using an expansion coupling, slide the halves onto the respective pipes and tighten the screws to create a secure and flexible connection.

10. Threaded Connections:

In some cases, you may have a threaded copper drain pipe that requires a connection to a PVC pipe. To make this connection, use a threaded PVC adapter or nipple with male threads on one end and female threads on the other.

Apply plumber’s tape or pipe thread compound to the male threads, and then screw the adapter or nipple onto the copper drain pipe. Insert the PVC pipe into the female end of the adapter or nipple and tighten it securely.

Conclusion

After discussing the various methods of connecting a PVC and copper drainpipe, we can conclude that there are many safe and affordable ways to complete this project. Additionally, certain steps need to be taken in order to ensure the stability and durability of the connection, no matter which method is chosen.

Ultimately, each project will require its own set of materials, tools and instructions; following all proper guidelines is key to achieving success when connecting PVC and copper drainpipes. It may appear daunting at first glance but with a little guidance anyone can confidently tackle this task like a pro.

So if you find yourself with a leaking pipe or an upcoming home improvement project – don’t forget about the different strategies involved in how to connect PVC to copper drain pipes! Remember proper safety measures should always be practiced when working around plumbing as not to create health risks or further damage. With accuracy and attention-to-detail one can easily do-it-yourself!