Properly crimping downspouts is an essential step in ensuring that your gutter system works efficiently and effectively. Crimping helps to securely join sections of downspouts together, preventing leaks and ensuring a smooth flow of water away from your home.

This guide explores the key aspects of how to crimp downspouts. Whether you are installing a new gutter system or repairing an existing one, understanding the basics of crimping can save time and effort while providing long-lasting results.

Why Crimping is Necessary for Proper Downspouts

Crimping plays a vital role in the functionality and durability of a downspout system. By securely connecting sections of the downspout, crimping ensures that water flows seamlessly from the gutters to the designated drainage area.

Without proper crimping, gaps or loose connections can form, leading to leaks that may damage your home’s foundation, siding, or landscaping. Additionally, crimping helps to prevent sections of the downspout from disconnecting during heavy rainfall or high winds, maintaining the integrity of the system.

Overall, crimping is an essential step for a reliable and effective gutter system that protects your home against water damage.

What Crimping Achieves

Crimping achieves a secure and watertight connection between sections of downspouts, which is crucial for the overall efficiency of the gutter system. By compressing the edges of one section into a compatible shape that fits snugly into the next, crimping creates a firm seal that prevents water from seeping through.

This process not only reduces the risk of leaks but also allows for a smooth and uninterrupted flow of rainwater toward the designated drainage area. Beyond functional benefits, crimping also enhances the structural stability of the system, ensuring that downspouts remain firmly connected and are less likely to separate under the strain of heavy rainfall or strong winds.

Types of Crimping Tools and Their Uses

Using the right crimping tools can make the process more efficient and ensure a professional, durable finish. Here are some of the most common types of crimping tools and their specific uses:

Hand Crimpers

Hand crimpers are the most widely used tool for small-scale gutter projects or minor repairs. These manual tools feature a set of sharp jaws designed to create precise crimps in the edges of downspouts. They are lightweight, easy to handle, and offer excellent control, making them a great option for DIY enthusiasts.

Snap Lock Punch Tools

These specialized tools are ideal for creating dimples or indentations that allow one section of the downspout to lock securely into another. Snap lock punch tools are particularly useful in ensuring tight, leak-free connections and are commonly used in professional gutter installations.

Powered Crimping Tools

Powered crimping tools are favored for larger or more complex projects where efficiency is crucial. These tools use electric or pneumatic power to create quick and consistent crimps with minimal effort. While they are more expensive than manual options, they are an excellent investment for contractors or anyone handling frequent installations.

Combination Tools

Combination crimping tools offer versatility by integrating crimping and cutting capabilities into a single device. These tools are perfect for projects requiring multiple tasks, helping to reduce the number of tools needed and streamline the process.

Selecting the appropriate tool depends on the scale of your project, your level of experience, and how frequently you expect to crimp downspouts. Each tool type has its own unique advantages, so understanding their uses will ensure your gutter system performs at its best.

10 Methods How to Crimp Downspouts

1. Understand the Purpose of Crimping

Before starting, it’s important to understand why crimping is necessary. Crimping creates a smaller, tapered end on the downspout that fits snugly into the next section or an elbow joint. This ensures a secure connection and prevents water from leaking at the joints. Familiarizing yourself with this purpose will help you approach the task with clarity.

2. Gather the Right Tools

To crimp downspouts effectively, you’ll need the proper tools. A pair of downspout crimpers is essential, along with gloves for protection and measuring tape for precision. Having all your tools ready will make the process smoother and more efficient.

3. Measure and Mark the Downspout

Accurate measurements are crucial for a proper fit. Use a measuring tape to determine where the downspout needs to be crimped. Mark the area with a pencil or marker, ensuring consistent alignment. Precise marking ensures that the crimping is done at the right spot for a secure connection.

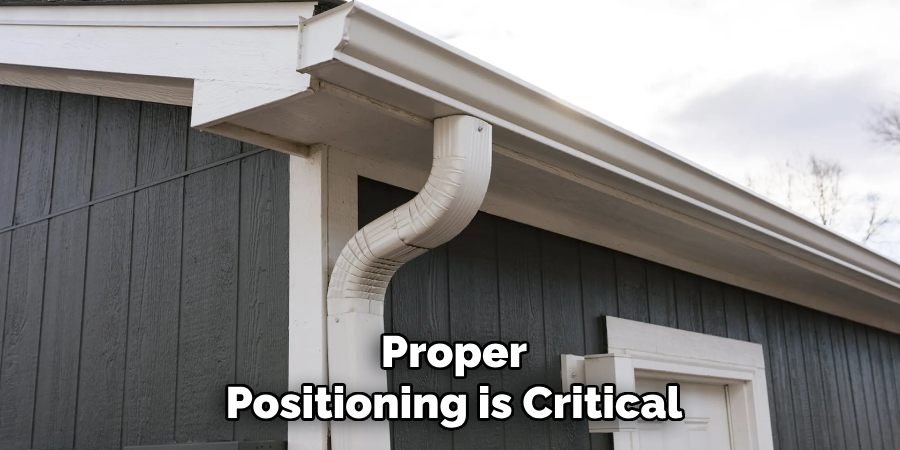

4. Position the Downspout Crimpers

Place the crimping tool at the marked section of the downspout. Ensure that the jaws of the crimpers align with the edges of the downspout. Proper positioning is critical for achieving an even crimp that allows for a tight fit.

5. Apply Even Pressure

Squeeze the handles of the crimpers firmly to create indentations in the downspout. Apply consistent pressure to ensure the crimps are even and uniform. Uneven crimps can result in a poor fit, leading to potential leaks or misalignments.

6. Rotate the Downspout

For a complete crimp, rotate the downspout slightly after each crimping action. This ensures that the entire circumference of the downspout is crimped evenly. Skipping this step can leave gaps, compromising the connection.

7. Test the Fit

After crimping, test the fit by inserting the crimped end of the downspout into the next section or an elbow joint. The connection should be snug but not overly tight. If the fit is too loose, additional crimping may be necessary. Testing ensures that the crimping was successful.

8. Seal the Joint

For added security and to prevent leaks, apply a bead of silicone sealant or gutter adhesive around the joint. This step is particularly important in areas prone to heavy rainfall. Sealing the joint provides extra protection against water seepage.

9. Secure the Connection

Once the downspout is crimped and fitted, secure the connection with screws or rivets. Use a drill or rivet gun to fasten the pieces together, ensuring they stay in place. This step adds durability and prevents the downspout from coming loose over time.

10. Inspect and Adjust

Finally, inspect the crimped section and the overall installation for any gaps or misalignments. Make adjustments as needed to ensure a smooth and secure fit. Regular inspection and adjustment can extend the lifespan of your gutter system and improve its performance.

Troubleshooting Common Issues

Even with proper tools and techniques, issues can occasionally arise during the crimping or installation process. Identifying and addressing these problems promptly can ensure a well-functioning gutter system. Here are some common issues and how to troubleshoot them:

1. Loose Connections

If the downspout sections are not fitting securely, double-check the quality of the crimps. Ensure the crimps are even and deep enough to create a snug fit. If the issue persists, try applying additional crimps or use a silicone sealant to fill any gaps.

2. Leaking Joints

Leaks at the joints may result from insufficient sealing or misaligned parts. Apply a fresh bead of silicone sealant or gutter adhesive around the joint. Make sure the crimped edge is fully inserted into the adjoining section before securing it. Tighten screws or rivets as needed to stabilize the connection.

3. Uneven Crimping

Uneven crimps can lead to gaps or poor alignment. Inspect the crimps for consistency and retrace your steps if necessary. Remove the uneven crimps using a mallet and carefully re-crimp the downspout, ensuring even pressure is applied during the process.

4. Crimping Tool Malfunction

If your crimping tool isn’t performing as expected, check for wear or damage to the jaws. Clean the tool to remove debris that might impact its efficiency. For significant problems, consider replacing the tool or upgrading to a higher-quality option.

5. Misaligned Downspouts

Misalignment can happen if the sections or joints are not properly measured and positioned. Remove the misaligned section, measure carefully again, and re-mark the appropriate spots before crimping. Reattach the downspout, ensuring all parts are in proper alignment.

6. Difficulty Fitting Sections Together

If the sections are too tight to fit, try gently widening the crimped end with pliers. Be cautious not to damage the downspout. If fitting remains challenging, inspect the crimping tool for inconsistencies or look for debris inside the downspout that might be obstructing the fit.

7. Rust or Corrosion Around Joints

Rust and corrosion can occur over time, particularly with older metal gutters. Remove rust with a wire brush and treat the area with a rust inhibitor or primer. To prevent future corrosion, consider applying a weather-resistant sealant or upgrading to rust-proof materials.

By troubleshooting these common issues effectively, you can maintain the integrity and performance of your gutter system for years to come. Regular maintenance and prompt repairs are key to preventing more significant problems in the future.

Conclusion

Properly crimping and installing downspouts is a critical step in maintaining an effective gutter system. Taking the time to measure, mark, and seal the joints correctly ensures that your gutters can efficiently divert water away from your home, protecting it from potential water damage.

following the recommended steps and addressing common issues with care, you can ensure a secure and long-lasting installation. So, there you have it – a quick and easy guide on how to crimp downspouts.