Cutting brass pipe is a fundamental skill for plumbers, metalworkers, and DIY enthusiasts, essential for various plumbing, construction, and crafting projects. Brass, valued for its corrosion resistance and durability, requires careful and precise cutting to ensure clean edges and proper fitment. Whether you’re installing new plumbing fixtures, creating custom fittings, or crafting decorative elements, understanding how to cut brass pipe effectively is crucial.

The process involves selecting the appropriate cutting tool, such as a hacksaw, pipe cutter, or rotary tool, and employing the correct technique to achieve straight, smooth cuts without damaging the pipe’s integrity. Additionally, taking safety precautions, such as wearing protective gear and securing the pipe properly, is essential to prevent accidents and injuries.

This guide will provide comprehensive instructions to cut brass pipe using various tools and techniques, empowering you to tackle your plumbing and crafting projects with confidence and precision.

Understanding Brass Pipe

Brass pipes are a popular choice in various applications due to their unique combination of properties. Composed primarily of copper and zinc, brass offers excellent corrosion resistance, which makes it ideal for plumbing systems where moisture and chemicals are a concern. The material’s durability ensures a long lifespan, even in demanding environments. Brass is also known for its workability, allowing it to be easily shaped and cut, making it suitable for intricate and custom fittings. Additionally, brass’s aesthetic appeal, with its warm, golden hue, makes it a favored material for decorative elements and fixtures. Understanding the characteristics and benefits of brass pipe can help you make informed decisions in your plumbing, construction, or crafting projects, ensuring optimal performance and longevity.

Common Brass Pipe Sizes and Dimensions

Brass pipes come in a variety of sizes and dimensions, catering to different needs and applications. The size of a brass pipe is typically described by its nominal diameter, which indicates the internal diameter of the pipe, and its wall thickness, which affects its overall strength and durability. Here are some of the common brass pipe sizes:

- 1/8 inch (3.2 mm) Nominal Diameter: Often used for small-scale plumbing and crafting projects, such as refrigerant lines and instrumentation.

- 1/4 inch (6.35 mm) Nominal Diameter: Commonly found in small water supply lines and air brake systems.

- 3/8 inch (9.5 mm) Nominal Diameter: Suitable for larger water distribution systems and gas lines.

- 1/2 inch (12.7 mm) Nominal Diameter: A standard size for many household plumbing systems, providing a balance of strength and flow capacity.

- 3/4 inch (19.05 mm) Nominal Diameter: Frequently used in both residential and commercial plumbing for larger water mains.

- 1 inch (25.4 mm) Nominal Diameter and above: Utilized in industrial applications and large plumbing systems where high flow rates are necessary.

10 Methods How to Cut Brass Pipe

1. Selecting the Right Tools

Before cutting brass pipe, it’s essential to gather the right tools for the job. The most common tools used for cutting brass pipe include hacksaws, tube cutters, pipe cutters, and reciprocating saws with metal-cutting blades. Each tool has its advantages and limitations, so choose the one that best suits your needs and preferences. Ensure that the blade or cutter is sharp and in good condition to achieve clean and precise cuts.

2. Measuring and Marking the Cut

Accurate measurements and markings are crucial for achieving the desired length of brass pipe. Use a tape measure or ruler to measure the length you need to cut and mark the pipe accordingly with a pencil or marker. Double-check your measurements to avoid mistakes and ensure the cut is made at the correct location. Consider using a pipe cutting guide or square to ensure straight and perpendicular cuts.

3. Using a Hacksaw

A hacksaw is a versatile tool commonly used for cutting metal, including brass pipe. To use a hacksaw, place the pipe securely in a vise or clamp to prevent it from moving during cutting. Position the hacksaw blade perpendicular to the pipe and align it with the marked cut line. Apply steady pressure and use long, smooth strokes to saw through the pipe. Take care to keep the saw blade straight to achieve a clean and accurate cut. Hacksaws are suitable for cutting brass pipes of various sizes and thicknesses.

4. Using a Tube Cutter

A tube cutter is a specialized tool designed specifically for cutting copper, brass, and other types of tubing. To use a tube cutter, place the pipe in the cutter’s jaws and tighten the cutter’s knob to secure it in place. Rotate the cutter around the pipe, gradually tightening the knob after each rotation until the pipe is cut through. Tube cutters provide clean and precise cuts without producing metal shavings or burrs, making them ideal for cutting brass pipe in tight spaces or confined areas.

5. Using a Pipe Cutter

A pipe cutter, similar to a tube cutter, is designed for cutting metal pipes, including brass pipe. To use a pipe cutter, position the cutter’s wheels on the marked cut line and tighten the cutter’s knob to secure it in place. Rotate the cutter around the pipe, applying even pressure until the pipe is cut through. Pipe cutters produce clean and square cuts without deforming the pipe or causing distortion, making them suitable for cutting brass pipe in plumbing and HVAC applications.

6. Using a Reciprocating Saw

A reciprocating saw equipped with a metal-cutting blade is an efficient tool for cutting brass pipe, especially for larger diameter pipes or thicker walls. To use a reciprocating saw, secure the pipe in a vise or clamp to prevent it from moving during cutting. Position the saw blade perpendicular to the pipe and align it with the marked cut line. Apply steady pressure and use a slow, controlled motion to cut through the pipe. Reciprocating saws are versatile and can cut through brass pipe quickly and effectively.

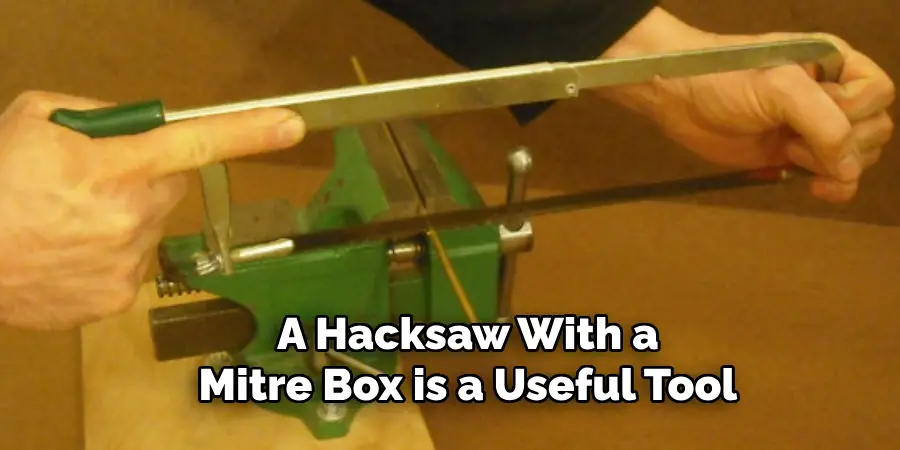

7. Using a Hacksaw with a Mitre Box

A hacksaw with a mitre box is a useful tool combination for achieving precise and angled cuts on brass pipe. A mitre box provides a guided platform for holding the pipe at the desired angle while cutting with a hacksaw. Place the brass pipe securely in the mitre box at the desired angle and align the hacksaw blade with the marked cut line.

Apply steady pressure and use long, smooth strokes to saw through the pipe. Hacksaws with mitre boxes are ideal for cutting brass pipe at specific angles for custom installations or repairs.

8. Using a Rotary Pipe Cutter

A rotary pipe cutter, also known as a rotary pipe cutter, is a handheld tool that uses rotary motion to cut through metal pipes, including brass pipe. To use a rotary pipe cutter, place the cutter’s wheels on the marked cut line and tighten the cutter’s knob to secure it in place. Rotate the cutter around the pipe, applying even pressure until the pipe is cut through. Rotary pipe cutters produce clean and precise cuts without distorting the pipe or creating burrs, making them suitable for cutting brass pipe in plumbing and HVAC applications.

9. Using a Bench Grinder

A bench grinder equipped with a metal-cutting wheel can be used to cut brass pipe, especially for thicker walls or larger diameter pipes. Secure the pipe in a vise or clamp to prevent it from moving during cutting. Position the bench grinder perpendicular to the pipe and align it with the marked cut line. Turn on the grinder and slowly feed the pipe into the rotating wheel, applying steady pressure until the pipe is cut through.

Bench grinders produce clean and accurate cuts with minimal effort, making them suitable for cutting brass pipe in fabrication or manufacturing settings.

10. Using a Portable Bandsaw

A portable bandsaw equipped with a metal-cutting blade is a versatile tool for cutting brass pipe, especially for on-site or remote cutting applications. Secure the pipe in a vise or clamp to prevent it from moving during cutting. Position the bandsaw blade perpendicular to the pipe and align it with the marked cut line. Turn on the bandsaw and slowly feed the pipe into the blade, applying steady pressure until the pipe is cut through. Portable bandsaws are lightweight and easy to maneuver, making them ideal for cutting brass pipe in tight or hard-to-reach spaces.

Conclusion

Cutting brass pipe requires precision, skill, and the right tools to achieve clean and accurate cuts. By following these ten comprehensive methods, you can cut brass pipe effectively for plumbing, HVAC, and various other applications. Whether using a hacksaw, tube cutter, pipe cutter, reciprocating saw, or specialized cutting tool, each method offers unique advantages and applications for cutting brass pipe. With proper techniques and equipment, you can ensure clean, square cuts without deforming the pipe or causing damage. Be sure to follow all instructions on how to cut brass pipe carefully, and always consult an expert when in doubt.