Cutting conduit is a fundamental skill required for electrical installations and projects. It involves precise measurements and proper tools to ensure clean cuts and effective connections.

Whether you’re working with metal or PVC conduit, understanding the correct techniques can save time and improve the quality of your work. This guide will walk you through the essential steps and considerations for how to cut conduit safely and efficiently.

Importance of Properly Cutting Conduit

Properly cutting conduit is essential for ensuring a safe and functional electrical system. Incorrect or imprecise cuts can lead to jagged edges, which may damage wiring insulation or create safety hazards during installation.

Clean, accurate cuts facilitate smooth connections and improve the overall durability and reliability of the conduit system. Furthermore, taking care to cut conduit properly reduces waste by minimizing errors and material loss, ultimately saving time and money on projects. Mastering this skill is a critical step in achieving professional-quality results in electrical work.

Types of Conduit

There are several types of conduit, each designed for specific applications and environments. Understanding the differences between these types ensures you select the right conduit for your project:

1. Rigid Metal Conduit (RMC)

RMC is a heavy-duty metal conduit typically made of galvanized steel. It provides excellent protection against physical damage and is commonly used in outdoor or industrial settings. Due to its strength, RMC is ideal for environments that require robust protection for electrical wiring.

2. Electrical Metallic Tubing (EMT)

EMT, often called “thin-wall” conduit, is a lighter and more flexible option compared to RMC. It is typically made of steel or aluminum and is used for indoor applications where less protection is needed. EMT is easy to bend and install, making it a popular choice for residential and commercial projects.

3. PVC Conduit

Polyvinyl chloride (PVC) conduit is a non-metallic option that is lightweight, durable, and resistant to moisture and corrosion. PVC is ideal for outdoor or underground applications, especially where exposure to chemicals or harsh weather conditions is expected. It is also a cost-effective alternative to metal conduits.

4. Flexible Metal Conduit (FMC)

FMC, also known as “Greenfield,” is a flexible conduit made of spirally wound metal strips. It is commonly used in spaces where rigid conduit is impractical, such as tight corners or areas with frequent vibrations. Flexible metal conduit provides moderate protection but is not suitable for outdoor or wet environments without special fittings.

5. Liquidtight Flexible Nonmetallic Conduit (LFNC)

LFNC is a flexible, non-metallic conduit with a waterproof jacket that protects against moisture and dirt. It is used in applications where wiring needs to remain water-resistant, such as outdoor lighting or pool equipment.

10 Methods How to Cut Conduit

1. Using a Pipe Cutter

A pipe cutter is a reliable tool for making clean and precise cuts on conduit. To use this method, secure the conduit in a vise or hold it steady on a workbench.

Place the pipe cutter around the conduit at the desired cut point and tighten the cutting wheel against the surface. Rotate the cutter around the conduit, gradually tightening it after each turn. This method works exceptionally well for EMT and rigid conduit, providing smooth edges that require minimal deburring.

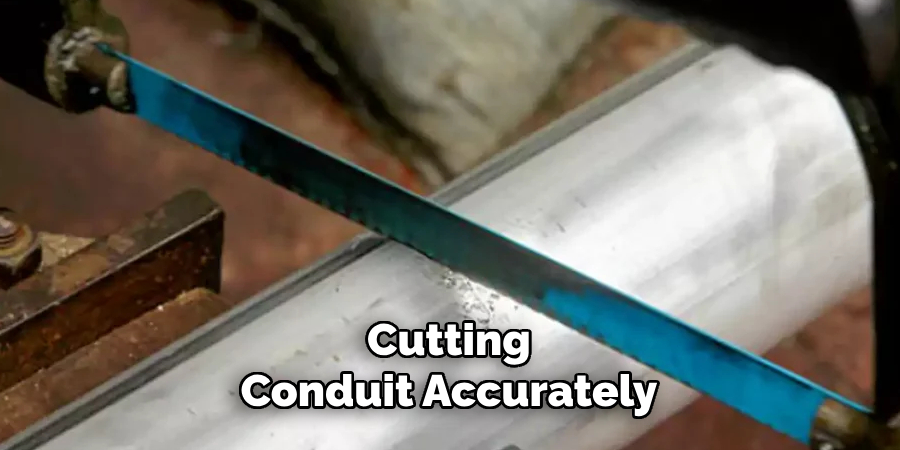

2. Employing a Hacksaw

The hacksaw is a versatile and readily available tool for cutting conduit. Begin by marking the cut line with a permanent marker or pencil. Secure the conduit in a vise to prevent movement, and carefully saw along the marked line using smooth, steady strokes.

A fine-toothed blade is ideal for clean cuts. Afterward, use a deburring tool or file to remove sharp edges. This method is budget-friendly and effective for both EMT and rigid conduit.

3. Using a Reciprocating Saw

A reciprocating saw is a powerful tool for cutting conduit quickly, especially for larger projects. Equip the saw with a metal-cutting blade and secure the conduit firmly before cutting.

Align the blade with your marked line and make the cut, applying consistent pressure. Reciprocating saws are excellent for cutting through thick or multiple conduits simultaneously, but ensure to maintain control for precision and safety.

4. Operating a Chop Saw

A chop saw, or miter saw, with a metal-cutting blade, is ideal for making fast and precise cuts on rigid conduit. Set the conduit on the saw’s cutting base, aligning it with the blade.

Hold it firmly in place and bring the blade down to make the cut. Chop saws are best suited for projects requiring repeated cuts of the same length, providing consistency and speed. Always wear safety goggles and gloves to protect against sparks and sharp edges.

5. Utilizing an Angle Grinder

An angle grinder equipped with a cutoff wheel is a highly effective tool for cutting conduit, especially for rigid and thick-walled types. Mark the cut line, then clamp the conduit securely.

Turn on the grinder and slowly guide the cutting wheel along the line. Angle grinders provide flexibility in cutting at angles or in tight spaces. However, this method can produce sparks, so ensure the workspace is free from flammable materials.

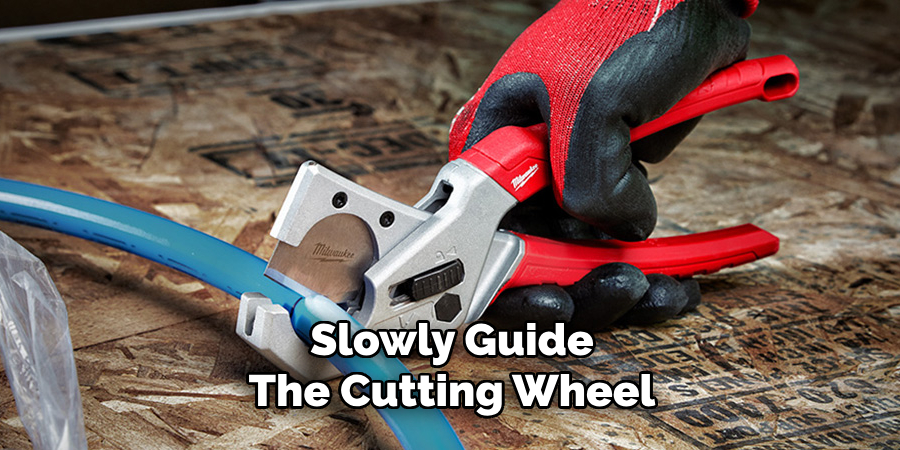

6. Cutting with a Tubing Cutter

Tubing cutters are designed for smaller-diameter conduits, particularly EMT. To use, place the cutter around the conduit, align it with the marked line, and tighten the cutting wheel against the surface.

Rotate the cutter around the conduit, gradually increasing pressure until the cut is complete. This tool ensures a clean, burr-free edge, making it perfect for applications where precision is critical.

7. Using a Circular Saw

A circular saw with a metal-cutting blade can be used for conduit cutting, especially for larger projects. Secure the conduit firmly, mark the cut line, and align it with the saw blade.

Turn on the saw and guide it steadily through the conduit. Circular saws are efficient for cutting through thick or large quantities of conduit. As this method generates heat and sparks, proper safety gear is essential.

8. Applying a Rotary Tool

A rotary tool with a cutting wheel attachment is a versatile option for conduit cutting, particularly in confined spaces. Mark the conduit and secure it in place. Turn on the rotary tool and guide the cutting wheel along the marked line with steady pressure.

This method is excellent for intricate cuts or small-diameter conduit. Although slower than other tools, the rotary tool provides precision and control.

9. Shearing with Conduit Cutters

Conduit cutters are specialized tools designed for EMT and thin-walled conduit. These hand-operated tools use a shearing action to slice through the conduit cleanly.

Position the conduit in the cutter’s jaws, align it with the marked line, and squeeze the handles to make the cut. This method is quick and produces minimal debris, but it is limited to smaller-diameter conduit and requires significant hand strength.

10. Using a Band Saw

A band saw with a metal-cutting blade is an excellent choice for precise and efficient conduit cutting. Clamp the conduit securely and guide it into the blade along the marked line.

Band saws are ideal for straight cuts on rigid and thick-walled conduit, providing clean and accurate results. This method is especially useful in workshops or for larger-scale projects where multiple cuts are required.

Things to Consider When Cutting Conduit

When cutting conduit, there are several factors to keep in mind to ensure safety, accuracy, and efficiency:

Type of Conduit

Different conduits, such as EMT, rigid, or flexible, require specific cutting tools and techniques. Ensure you select a method that suits the material and thickness of the conduit.

Accuracy

Always mark the conduit clearly before cutting to achieve precise measurements. Using measurement tools like a tape measure and a marker can help ensure consistency.

Safety Gear

Always wear safety equipment, including gloves, safety goggles, and ear protection. Many cutting methods produce sparks, sharp edges, or noise, so personal protection is essential.

Tool Selection

Choose a tool appropriate for the project scale and the material being cut. For a single conduit, hand tools like a hacksaw may suffice, while larger projects may require power tools like a reciprocating saw or chop saw.

Workspace Setup

Ensure the workspace is clean, well-lit, and free of flammable materials. Secure the conduit firmly using a vise or clamps to prevent movement during cutting.

Deburring Edges

After cutting, the edges of the conduit may be sharp or rough. Use a deburring tool or file to smooth the edges, preventing injuries and ensuring proper fittings.

Compliance with Codes

Check local electrical codes and standards to ensure the cuts and overall conduit installation meet required regulations. This step is particularly important in professional and commercial projects.

Conclusion

Cutting conduit accurately and safely is an essential skill for both professional electricians and DIY enthusiasts working on electrical projects. By understanding the different tools and techniques available, as well as the specific requirements of each type of conduit, you can achieve clean, precise cuts while prioritizing safety.

Always take the time to prepare your workspace, use the appropriate tools, and follow safety guidelines to ensure a successful and efficient process.