Copper pipes are a staple in plumbing due to their exceptional durability and resistance to corrosion, ensuring a long-lasting and reliable water supply system. However, when faced with the task of cutting these pipes in tight spaces, several challenges arise. Limited access can make it difficult to maneuver and position tools correctly, often increasing the risk of damaging nearby surfaces or fixtures.

Additionally, using standard-sized tools in such confined areas can prove cumbersome, reducing the efficiency and precision of the cut. This article is designed to provide practical solutions and innovative techniques on how to cut copper pipe in tight space settings. By exploring a range of specialized tools and methods tailored for these tricky situations, we aim to empower DIY enthusiasts and professionals alike with the knowledge to perform clean and accurate cuts, ensuring the seamless installation and maintenance of copper piping systems.

Tools for Cutting Copper Pipe in Tight Spaces

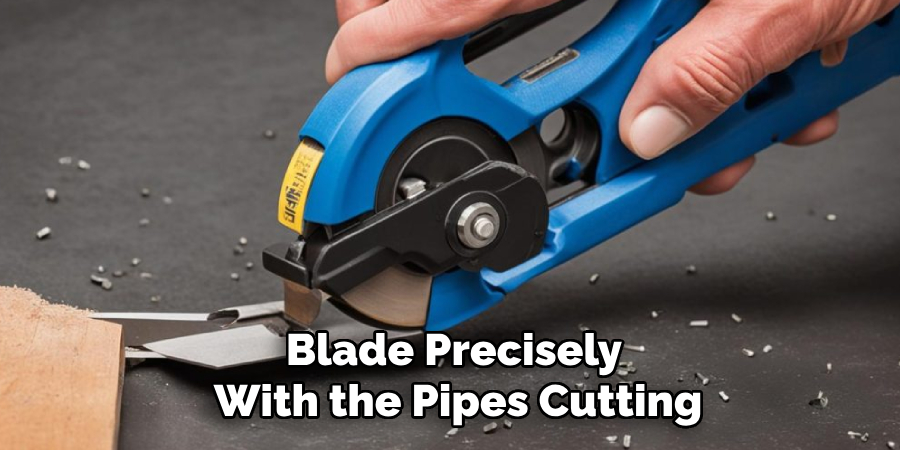

When confronted with the challenge of cutting copper pipes in cramped environments, selecting the right tools can make all the difference. One of the most effective tools for this purpose is the Mini Tubing Cutter. Its compact design allows for easy maneuverability in confined areas, making it ideal for tight spaces. To use it properly, position the cutter around the pipe and tighten the blade using the knob until it grips the pipe securely.

Then, rotate the cutter around the pipe, gradually tightening after every few rotations until the pipe is severed.

For situations where rotating tools are impractical due to minimal space, a Hacksaw with a Fine-tooth Blade is recommended. This tool is particularly beneficial for its ability to make precise cuts without excessive rotational movement. To achieve a clean cut, make steady and controlled strokes, ensuring the blade moves in a straight line to minimize burrs or jagged edges, which could impact the fit of pipe connections.

The Oscillating Multi-Tool is another versatile option, especially in extremely tight or awkward spaces. Equipped with suitable attachments, this tool can effectively slice through copper pipes. It’s crucial to align the blade with the cutting line and employ best practices to maintain accuracy and prioritize safety during use.

Finally, a Pipe Snap Cutter is perfect for making quick and clean cuts on small-diameter pipes in constrained spaces. It functions by gripping the pipe and applying pressure, snapping it cleanly without the need for extensive movement, making it a valuable addition to the toolbox when dealing with space limitations.

Preparing for the Cut

Assessing the Work Area

Before beginning the pipe-cutting process, it’s crucial to thoroughly assess the work area for any potential obstacles. Look for nearby walls, other pipes, fixtures, or any other structural elements that might impede the operation. Identifying these obstacles enables you to strategically plan your cutting approach, ensuring that there is enough room to maneuver your chosen tool efficiently.

This preliminary step helps prevent accidental contact with surrounding structures, which could cause damage or require additional repairs.

Securing the Pipe

Once the work area is evaluated, focus on securing the pipe to prevent movement during the cutting process. Use clamps or supports to hold the pipe firmly in place. This will not only help achieve a straight and even cut but also avoid tool slippage that might create uneven cuts or injury. Ensuring a stable pipe helps maintain the integrity of the cut surface, simplifying subsequent soldering or fitting installations.

Protecting Surrounding Surfaces

Protective measures should be taken to safeguard adjacent surfaces from accidental damage. Applying shields or taping around the cutting area can prevent scratches or dents on walls and floors. These precautions are essential in maintaining the aesthetics and structural integrity of the surrounding environment, contributing to a smooth and clean-cutting project.

How to Cut Copper Pipe in Tight Space: Step-by-Step Guide

Using a Mini Tubing Cutter

- Positioning the Cutter: In cramped conditions, carefully slide the mini tubing cutter around the pipe. Ensure that the cutter’s blade is in contact with the intended cutting line and that the handles have enough room to rotate without obstruction.

- Techniques for Smooth Rotations: Once positioned, gradually tighten the cutting wheel by turning the knob. Rotate the cutter around the pipe, applying a firm yet gentle pressure. Tighten slightly after each complete rotation to ensure a clean cut, and continue rotating until the pipe is severed.

Using a Hacksaw

- Achieving a Straight Cut: To ensure a straight cut, mark the cutting line clearly on the pipe. Holding the hacksaw with a fine-tooth blade, use slow, even strokes to create an initial groove that will guide the blade through the pipe.

- Tips to Minimize Burrs: Maintain a consistent, controlled motion throughout the cutting process. Pay attention to the alignment of the blade, and after cutting, use a deburring tool to remove any jagged edges or burrs, ensuring a smooth finish.

Using an Oscillating Multi-Tool

- Aligning the Blade: Equip the multi-tool with a suitable metal-cutting blade. Align the blade precisely with the pipe’s cutting line, ensuring the tool’s body is stable.

- Best Practices for Accuracy and Safety: Gently guide the tool along the cutting line, using steady hands and applying minimal force. Keep your work area clutter-free to enhance safety, and wear appropriate protective gear, such as goggles and gloves, to prevent accidents.

Post-Cut Finishing

Deburring the Pipe

After cutting the copper pipe, it’s essential to address the edges to ensure smooth connections. Using a deburring tool is the most efficient way to remove burrs and sharp edges left behind from the cutting process. Simply run the tool around the inner and outer edges of the pipe to produce a clean, uniform finish. Alternatively, fine-grit sandpaper can be employed similarly to eliminate imperfections.

This step is crucial; leftover burrs can obstruct the proper seating of fittings, leading to potential leaks or structural issues in the piping system. Ensuring burr-free edges promotes a tighter seal and increases the longevity and reliability of the pipe connections.

Cleaning the Pipe Ends

Once deburring is complete, clean the pipe ends to prepare them for the next phase—whether soldering or fitting installation. Use a damp cloth to remove dust, metal shavings, or debris lingering on the pipe’s surface. This cleaning process ensures optimal adherence of solder or fittings, preventing contaminants from compromising the joint integrity.

Properly cleaned and prepped pipe ends facilitate smoother assembly and ensure a more robust, leak-proof installation, providing peace of mind and efficiency in plumbing projects.

Safety Tips for Cutting Copper Pipes in Tight Spaces

Safety should be prioritized when working in tight spaces to prevent injury and damage to surrounding areas. Begin by equipping proper protective gear; gloves are essential to shield your hands from sharp pipe edges and potential cuts, while goggles protect your eyes from flying metal fragments during cutting. It’s crucial to handle your tools with care to avoid inadvertently hitting or damaging nearby materials such as walls, other pipes, or fixtures.

This requires controlled movements and a steady hand, especially when using power tools, which can easily slip if not properly managed. Ensuring stability is another key aspect of safe pipe cutting. Use adequate supports like clamps to secure the pipe, preventing any unintended movement that could lead to uneven cuts or tool accidents. Adhering to these safety protocols minimizes the risk of personal injury. It maintains the structural integrity of both the workpiece and the immediate surroundings, facilitating a more efficient and worry-free project environment.

Common Mistakes to Avoid

When cutting copper pipes, selecting the right tool that matches the space constraints and the pipe’s diameter is essential. Using an inappropriate tool can lead to inaccurate cuts, causing fitting issues down the line. Additionally, applying too much pressure while cutting is a frequent mistake that can result in uneven cuts, excessive burrs, or even damage to the cutting tool itself.

Such errors compromise the pipe’s structural integrity, leading to potential misalignments and leaks. Another crucial step often neglected is deburring. Skipping this process leaves sharp, uneven edges on the pipe, preventing a snug fit with fittings or causing leaks. Ensuring smooth pipe edges is vital for creating tight, reliable seals. By being aware of these common pitfalls and taking the necessary precautions, one can achieve cleaner cuts, better fits, and more effective plumbing installations.

Conclusion

In conclusion, mastering how to cut copper pipe in tight space requires carefully selecting effective tools combined with applying correct techniques. Clean and precise cuts are achievable by using a mini tubing cutter, hacksaw, or oscillating multi-tool, provided proper preparation is observed. Prioritizing safety by using appropriate protective gear and ensuring stable working conditions is crucial. Don’t overlook the importance of deburring and cleaning to ensure smooth pipe connections. Above all, choosing the right tool for the specific job and showing patience, especially in confined spaces, will lead to successful and enduring plumbing installations.