Cutting holes in the vanity is an important part of installing floor plumbing. It allows for proper alignment of the pipes and fixtures, ensuring that the plumbing system will function properly and be safe. When done correctly, cutting holes in your vanity can save you time and money by helping avoid costly repairs.

Cutting the holes for plumbing in the vanity can have many advantages. When done correctly, it allows access to all of the plumbing fixtures within a bathroom without needing to move or remove any other furniture or fixtures.

Additionally, having these holes cut ahead of time simplifies and speeds up the installation process and reduces potential mistakes that could be made during the process. In this blog post, You will learn in detail how to cut holes in vanity for floor plumbing.

Tools You Will Need

- Safety glasses

- Measuring tape

- Pencil

- Jigsaw

- Drill with a bit that matches the diameter of the plumbing pipes

- Stud finder

- Level

- Cardboard template of the hole to be cut in the vanity top

- Plunge router

- Screwdriver or screw gun

Step by Step Processes for How to Cut Holes in Vanity for Floor Plumbing

Step 1: Inspect the Vanity

Before you begin to cut holes in the vanity, examine it for any pre-existing damage and make sure that all of the necessary parts are present. This includes a drill bit, saw blade, ruler or measuring tape, level, chisel, and hammer.

Step 2: Measure Out the Hole Size

Using your ruler or measuring tape, measure out the dimensions of the hole size that you wish to cut. Mark these measurements on the vanity using a pencil or marker. Put on safety goggles before beginning to drill. Attach the appropriate drill bit size to the drill and make sure that the bit is secured tightly.

Step 3: Drilling Out the Holed

Carefully start drilling along the marks that you made earlier, making sure not to jerk too quickly or forcefully, as this could damage your vanity. Drill at a steady pace, and stop drilling once the desired hole size has been achieved.

Once you have finished drilling out the hole, take a vacuum cleaner to remove any debris that may be present in the drilled area. Use gentle pressure while vacuuming, as too much pressure could damage the vanity.

Step 4: Measure Again and Cut Out the Hole

Once the area is clean, measure out the hole size again to make sure that nothing has shifted during drilling. Take a saw blade and cut out the remaining area of the vanity that was not drilled away earlier. Ensure your cutting is accurate, as any mistakes could damage the vanity.

Step 5: Sanding Away Any Rough Edges

After you have finished cutting out the hole size, use a sander or sandpaper to smooth away any rough edges. This will give your vanity a professional finish and protect it from further damage. Once you have finished sanding away any rough edges, re-inspect the vanity to ensure that all of the necessary parts are present and undamaged.

Step 6: Installing the Floor Plumbing

Now you can begin installing the floor plumbing into your newly cut holes. Make sure to follow the instructions provided for your particular plumbing setup. Once you have successfully installed the floor plumbing, use a caulking gun to seal any cracks or crevices around the hole.

Be sure to apply an even amount of caulk and smooth it out with a damp cloth. Wait until the caulk has completely dried before using the vanity.

Following these steps will help you successfully cut a hole in your vanity for floor plumbing. Remember to take safety precautions while drilling and cutting, and use caution when handling tools or materials.

Safety Tips for How to Cut Holes in Vanity for Floor Plumbing

- Wear safety glasses to protect your eyes from dust, debris, and flying particles that may enter your eye when cutting the vanity.

- Wearing ear protection such as earmuffs or earplugs can help keep your hearing safe when using power tools.

- When cutting the vanity, wear a respirator mask to ensure that you are not breathing in toxic particles or fumes.

- Wear work gloves to protect your hands from sharp edges and splinters when cutting the vanity.

- Make sure that the vanity is stable before cutting by placing it on a flat, level surface.

- To prevent slippage when cutting, use clamps to secure the vanity in place.

- Make sure that any power cords are out of the way and not in contact with the saw blade or cutting surfaces.

These are just a few safety tips to keep in mind when cutting holes in the vanity for floor plumbing. Always make sure that you follow all safety protocols and that you wear the appropriate protective gear when performing any type of construction or DIY project.

How Much Space Do You Need Around the Pipe for the Best Results?

Cutting a hole in the vanity for floor plumbing requires careful planning, measuring, and precision. It is important to leave enough space around the pipe so that it can be properly connected and sealed. Most professionals recommend leaving an inch or two of space around the circumference of the pipe when cutting a hole in the vanity.

This allows room for the pipe to be connected and any necessary seals or gaskets to be added. This extra space also makes it easier to make sure that the hole is cut accurately and correctly.

When measuring, you should take into consideration where the pipes will sit within the vanity’s drawer or cabinet, as well as any other accessories, such as handles, knobs, or drawers, that will be installed. By measuring the area carefully and leaving enough space around the pipe, you can ensure that your project is a success.

It is also important to remember that the level of accuracy needed when cutting holes in vanities varies depending on the type of vanity being used. While some vanities require only a basic level of accuracy, others must be cut with exact precision to ensure that everything fits correctly and securely.

What Kind of Sealant Should You Use to Prevent Leaks Around the Edges of the Holes in Your Vanity for Floor Plumbing?

When you’re cutting holes in your vanity for floor plumbing, it’s important to use the right kind of sealant to prevent leaks around the edges. The most important factors to consider are durability and flexibility; you want a sealant that will last and won’t crack or break when exposed to water.

Silicone caulk is a popular choice for this job because it can withstand moisture, heat, and pressure. It’s also flexible enough to move with the vanity as it expands and contracts over time, which helps keep the sealant from cracking or breaking. Silicone caulk is easy to apply, too; just make sure you smooth it out before it dries to ensure a tight seal.

Another option is polyurethane caulk, which is also durable and flexible. This type of caulk is slightly more difficult to apply than silicone, as it takes more time and effort to smooth out the surface before it dries. However, it’s still an effective sealant for protecting against leaking around the edges of your vanity for floor plumbing.

Finally, specialized sealants are specifically designed for use in bathrooms and other moist environments. These sealants provide excellent protection against moisture and mold, allowing you to enjoy a longer-lasting solution for keeping water out of your vanity area.

Are There Any Common Mistakes to Avoid When Cutting Holes in Your Vanity for Floor Plumbing?

When cutting holes in your vanity for floor plumbing, there are some common mistakes to avoid. For instance, it is important to make sure that you measure twice and cut once. If you do not take proper measurements, the hole may end up being too large or too small for the pipes to fit through.

Additionally, it is also important that you make sure the hole is centered so it will fit correctly. If your hole is off-center, then the plumbing may not line up with the pipes on the floor.

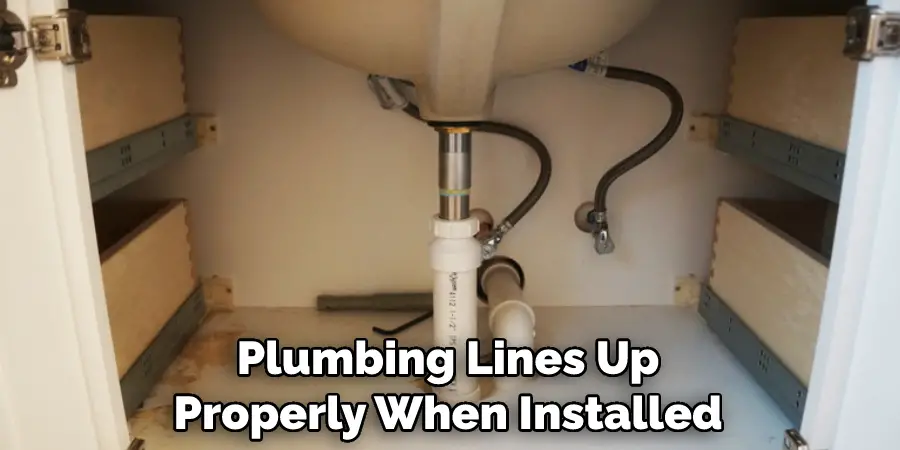

Another mistake to avoid when cutting holes in your vanity for floor plumbing is using too much force. It is important to take care when cutting and use a jigsaw rather than a power saw or other tools. This will help prevent damaging the vanity and ensure that the hole is cut accurately. Finally, be sure to use a template for your holes.

This can allow you to ensure that both holes are even so the plumbing lines up properly when installed. Ensuring everything is even will help prevent future problems with the plumbing. By following these simple tips, you can avoid common mistakes when cutting holes in your vanity for floor plumbing and ensure that everything is done correctly.

Conclusion

In conclusion, cutting holes in vanity for floor plumbing can be daunting for the novice DIYer. However, it can be accomplished successfully with the right tools and careful planning. The key is to measure accurately, use the correct saw blade, ensure that your cuts are straight, and even ensure a good fit.

Taking your time will help you achieve great results. With a bit of patience and practice, you’ll be able to cut holes in your vanity for floor plumbing confidently. I hope this article has been beneficial for learning how to cut holes in vanity for floor plumbing. Make Sure the precautionary measures are followed chronologically.