Are you planning to cut stainless steel tubing for a DIY project or professional work? Cutting stainless steel can be daunting, but with the right tools and techniques, it can be done easily and efficiently.

How to cut stainless steel tubing requires precision, the right tools, and an understanding of the material to achieve a clean and accurate result. Stainless steel is a durable and corrosion-resistant alloy, making it a popular choice for a range of applications, from construction to automotive projects. However, its strength also poses challenges when cutting through it without damaging the tubing or compromising its integrity.

This guide will walk you through the essential steps and tools needed to cut stainless steel tubing while ensuring safety and efficiency.

What Are the Benefits of Stainless Steel Tubing?

Before we delve into the cutting process, it’s essential to understand why stainless steel tubing is a popular choice for various applications.

- Durability: Stainless steel tubing is known for its strength and resistance to corrosion, making it an ideal material for outdoor and industrial use.

- Cleanliness: Due to its non-porous surface, stainless steel is easy to clean and maintain, making it suitable for food processing and medical applications.

- Aesthetics: With its shiny appearance and modern look, stainless steel tubing adds a sleek touch to any project or structure.

These benefits make stainless steel tubing a top choice for many industries, but it also requires specialized tools and techniques for cutting.

What Will You Need?

To cut stainless steel tubing, you will need the following tools:

- Safety Equipment: Stainless steel is a rigid material that can produce sharp edges when cut. It’s crucial to wear safety goggles, gloves, and protective clothing to prevent injuries.

- Hacksaw or Tube Cutter: These tools are suitable for cutting small diameters of stainless steel tubing up to 1 inch in diameter.

- Angle Grinder or Circular Saw: An angle grinder with a cutting wheel or a circular saw with a metal cutting blade will be more efficient for larger diameters.

- Clamps: Clamping the tubing securely before cutting ensures accuracy and stability.

- Deburring Tool: After cutting, a deburring tool will smooth any rough edges and remove sharp burrs for a clean finish.

Once you have gathered all the necessary tools, it’s time to start cutting.

10 Easy Steps on How to Cut Stainless Steel Tubing

Step 1. Measure and Mark the Tubing:

Use a measuring tape or ruler to determine the desired length of the cut. Ensure that your measurements are precise, as minor errors can impact the final result. Once you’ve measured, use a permanent marker or grease pencil to draw a clear line around the tubing at the point where it needs to be cut. For accuracy, you can use a tube marking tool or a straight-edged object to help guide the marker. This step is crucial as it is the guideline for your cut, ensuring that the finished product is straight and even. Double-check your measurements and markings before proceeding to avoid mistakes.

Step 2. Secure the Tubing:

Place the stainless steel tubing in a vise or a tube holder to hold it firmly. Ensure the tubing is tightly clamped, but avoid over-tightening, which may damage or distort its shape. A stable and fixed position is essential to prevent movement

during cutting, which could result in uneven or inaccurate cuts. A stable workspace is equally critical if you’re using a handheld tool. Always ensure the tubing is aligned with the cutting tool to achieve a clean, precise cut.

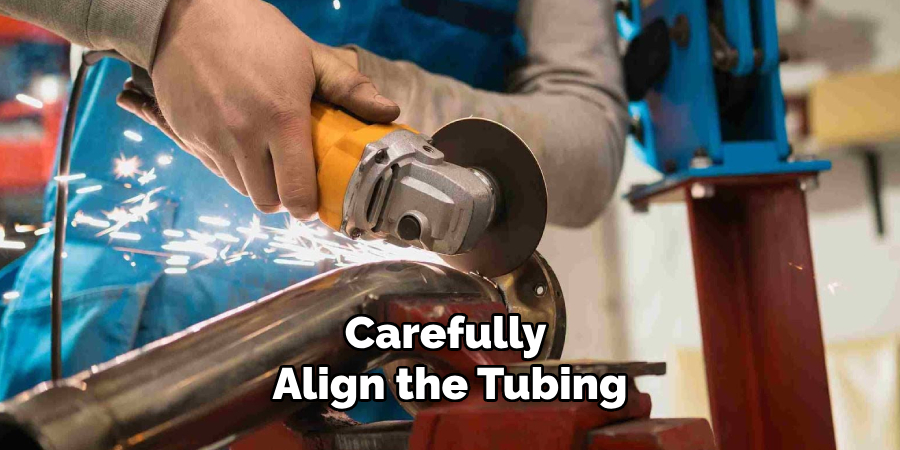

Step 3. Cut the Tubing:

Using the appropriate cutting tool for stainless steel tubing, such as a tubing cutter, hacksaw, or powered cutting tool, carefully make your cut along the marked guidelines. Apply steady, even pressure as you cut, ensuring the tool meets the guidelines. If using a powered tool, follow the manufacturer’s safety instructions and maintain a controlled speed to avoid overheating or uneven cuts. Take your time to prevent jagged edges or burrs. Once the cut is complete, inspect the tubing to ensure the cut is clean and straight, and make any necessary adjustments if imperfections are present.

Step 4. Deburr and Clean the Tubing:

After cutting, it’s essential to deburr the edges of the tubing to remove any sharp metal fragments or burrs that can affect the fit or safety of the installation. Use a deburring tool or fine metal file to smooth out the edges. Gently run the tool along the inner and outer edges of the cut until they are smooth to the touch. Once deburring is complete, clean the tubing thoroughly with a cloth to remove any metal shavings or debris. This ensures the tubing is safe to handle and ready for the next step in your project.

Step 5. Fit and Secure the Tubing:

With the tubing cleaned and prepared, the next step is to fit it into its designated position. Carefully align the tubing with the connector or fitting, ensuring a snug fit without forcing it, as this could damage the material. If applicable, use a

wrench or appropriate tool to tighten any fittings, but be cautious not to overtighten as this may cause stress on the tubing. Double-check the alignment and ensure all connections are secure to prevent leaks or instability in the installation.

Step 6. Test for Leaks and Finalize Installation:

Once the tubing is securely in place, testing the system for leaks or defects is essential. Slowly introduce pressure or fluid into the system while carefully inspecting all connections for any signs of leakage. If a leak is detected, stop the flow, re-tighten fittings as necessary, or reseal connections. After confirming the system is leak-free, double-check the entire installation for proper alignment and stability. This final step ensures the system operates safely and efficiently, completing the installation process.

Step 7. Maintenance and Regular Inspections:

To ensure the longevity and efficiency of the system, establish a routine for maintenance and inspections. Periodically check all fittings, connections, and tubing for wear, leaks, or damage. Replace any compromised components promptly to prevent system failures. Keep the system clean by removing debris or buildup that may hinder performance. Regular maintenance enhances the system’s reliability and helps identify potential issues before they escalate into significant problems.

Step 8. Troubleshooting Common Issues:

Even with proper installation and maintenance, issues may occasionally arise in the system. Check for leaks or loose connections if the system is not operating as expected. Inspect the tubing and fittings for cracks or blockages that may impede functionality. Verify that the system’s pressure and flow rate align with the manufacturer’s specifications for performance issues. If problems persist, consult the user manual or seek professional assistance. Addressing these common issues promptly ensures the system continues to function optimally.

Step 9. Upgrading the System for Enhanced Performance:

Consider upgrading the system with modern components or features to maximize efficiency and adapt to evolving needs. Start by evaluating the current system’s performance and identifying any limitations. Technology advancements, such as improved filtration systems, automated controls, or energy-efficient components, can significantly enhance functionality. Before making any upgrades, ensure compatibility with existing parts and verify that the new components meet the system’s requirements. Proper planning and installation of upgrades can extend the system’s lifespan and optimize its overall performance.

Step 10. Keep Learning and Exploring:

Cutting and installing stainless steel tubing is a valuable skill that can be applied to various projects. As you gain experience, continuously explore new techniques and tools to improve your proficiency. Expand your knowledge by learning about different types of stainless steel tubing, their applications, and best practices for handling and installation. With dedication and practice, you can become proficient in working with stainless steel tubing, opening up a world of possibilities for your future projects.

By following these steps and continuously learning, you can confidently tackle any project that requires cutting and installing stainless steel tubing.

5 Things You Should Avoid

- Using the Wrong Tools: Avoid improper tools like wood saws or dull blades, as they can damage the tubing and produce uneven cuts. Always choose tools specifically designed for cutting stainless steel, such as tube cutters or angle grinders with appropriate blades.

- Skipping Safety Precautions: Never overlook safety measures. Cutting stainless steel tubing can produce sharp edges and flying debris, so wearing protective gloves, goggles, and other safety equipment is essential to prevent injuries.

- Applying Excessive Force: Forcing the cutting tool through stainless steel can lead to jagged edges and damage your equipment. Use steady and consistent pressure to achieve clean, precise cuts while preserving the lifespan of your tools.

- Ignoring Proper Measurement: Failing to measure accurately before cutting can lead to wasted material and incorrect lengths. Always double-check your measurements and mark the tubing properly to ensure precision.

- Overheating the Tubing: Cutting too quickly or without cooling methods can cause the tubing to overheat, leading to discoloration or warping. Utilize cutting fluids or take breaks to allow the material to cool and maintain its integrity.

Conclusion

How to cut stainless steel tubing requires careful attention to detail and adherence to proper techniques to ensure optimal results.

By avoiding common mistakes such as neglecting safety precautions, applying excessive force, ignoring accurate measurements, and overheating the tubing, you can achieve clean and precise cuts while preserving the quality of your tools and materials. Always prepare adequately, use the right tools, and take a methodical approach.

With these steps in mind, you can handle stainless steel tubing cutting projects efficiently and safely.