Are you tired of listening to those loud, obnoxious foghorn pipes? Do you want to fix them once and for all? Follow these steps to rid yourself of this annoying problem.

Foghorn pipes play a crucial role in maritime navigation, serving as a reliable means for vessels to detect hazards in foggy conditions. Over time, however, these pipes can become clogged or damaged, reducing their effectiveness in producing sound. Understanding how to fix foghorn pipes is essential for maintaining safety at sea.

In this guide, we will explore common issues that affect foghorn pipes, provide step-by-step instructions for repairs, and offer maintenance tips to ensure optimal functionality. Whether you’re a seasoned sailor or new to maritime operations, this information will help you keep your foghorn system in shape.

What Will You Need?

Before you begin the repair process, gather all the necessary tools and materials. Here’s a list of items that you may need:

- Safety gear, such as gloves and eye protection

- Screwdrivers (flathead and Phillips)

- Wrenches or pliers

- Replacement parts (if required)

- Cleaning supplies (e.g., brushes, rags)

Make sure to have these items on hand before proceeding with the repairs.

10 Easy Steps on How to Fix Foghorn Pipes

Step 1. Safety First:

Before diving into the repair process, it’s imperative to prioritize safety. Always ensure that you wear appropriate safety gear, including gloves and eye protection, to shield yourself from hazards like sharp edges or chemical cleaners that could cause irritation or injury.

If you’re working on a foghorn system mounted on a vessel, make sure the ship is stable and securely anchored to prevent any accidental movement. Additionally, inform others onboard about your repair work to avoid distractions or unexpected situations. By taking these precautions, you protect yourself and create a safe work environment that enhances your focus on the task at hand.

Step 2. Inspect the Foghorn System

Begin your repair process by inspecting the foghorn system thoroughly. Check for any visible signs of damage, such as cracks, dents, or corrosion on the foghorn casing and pipes. Pay close attention to the connections, ensuring they are secure and free of leaks.

If you detect any loose parts, tighten them carefully using the appropriate tools. Additionally, examine the internal components of the foghorn, as foreign objects or debris can impede its function. If the foghorn is not accessible, make sure to consult any schematic diagrams or manuals specific to your model to understand the layout and critical areas that require inspection.

Step 3. Clear Any Obstructions

Once you’ve inspected the system, it’s time to clear any obstructions. Use cleaning supplies such as brushes and rags to remove dirt, dust, or salt buildup from the foghorn.

Pay special attention to the sound emitters and pipes since blockages here can significantly reduce sound output. In some cases, you may need to disassemble certain parts of the foghorn to access hard-to-reach areas. Be sure to note how components are arranged to facilitate easy reassembly later.

Step 4. Replace Damaged Parts

If you identified any damaged or worn-out parts during your inspection, it’s crucial to replace them to ensure the foghorn operates efficiently. Refer to your foghorn’s manual to find the correct replacement parts, and make sure they are designed specifically for your foghorn model.

Carefully remove any broken components using the necessary tools and install the new parts precisely, following the manufacturer’s instructions for a secure fit.

Step 5. Test the Air Supply

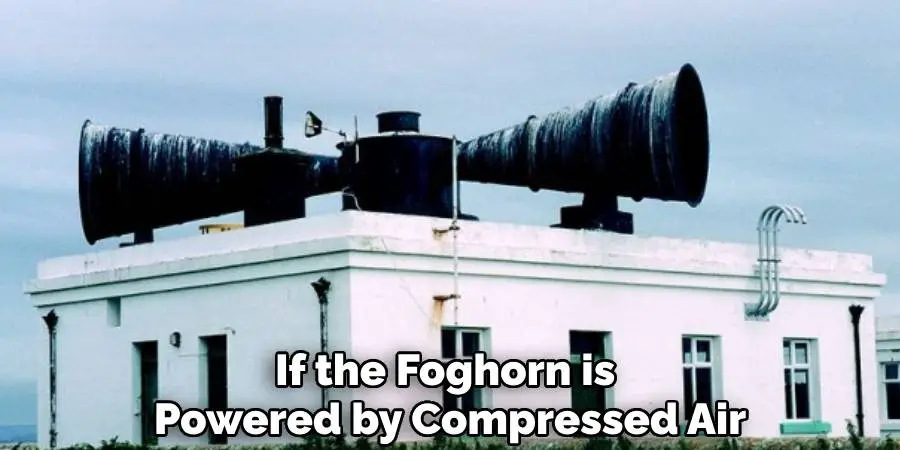

After addressing any necessary repairs, check the air supply to the foghorn. A consistent and sufficient air pressure is vital for proper operation. If the foghorn is powered by compressed air, ensure that the air compressor is functioning properly and that hoses are free from leaks.

If issues are detected, rectify them before proceeding. Testing the air pressure can usually be done by releasing a small amount of air while the system is activated, listening for any irregular sounds.

Step 6. Reassemble the Foghorn

Once you’ve cleared obstructions, replaced any damaged parts, and confirmed that the air supply is functioning correctly, it’s time to reassemble the foghorn. Carefully reconnect all components in the reverse order of disassembly. Ensure that all screws, bolts, and fittings are tightened securely to prevent any parts from loosening during operation.

Take special care to line up the parts accurately, as misalignment can lead to operational issues. As you reassemble, double-check that seals or gaskets are correctly positioned to prevent air leaks. After everything is in place, gently shake the foghorn to ensure nothing rattles or feels loose. Taking the time to reassemble correctly can save you future headaches and ensure the longevity of your foghorn system.

Step 7. Conduct a Functional Test

Once the foghorn is reassembled, conducting a functional test is crucial to verify that everything is operating correctly. Power up the foghorn and check the sound output by activating it briefly. Listen for a clear, robust sound that indicates proper functionality.

Observe for any abnormalities, such as sputtering or diminished volume, as these could signal underlying issues that still need addressing. If the foghorn does not perform as expected, take the time to reevaluate each step completed earlier, investigating potential sources of airflow blockages or electrical faults.

Step 8. Perform Regular Maintenance

To ensure your foghorn remains in good working order, establish a regular maintenance schedule. This can include monthly visual inspections, cleaning out debris, and checking connections for rust or corrosion.

It’s also wise to test the sound output periodically to catch any problems early on. Keeping a maintenance log can help track your efforts and schedule any potential replacements or significant repairs ahead.

Step 9. Familiarise Others with the System

If you’re working on a vessel with other crew members, it’s essential to inform them about the foghorn system and any repairs made. Ensure everyone knows how to operate the foghorn effectively in case of emergencies and discuss emergency protocols related to sound signals.

This will foster a better understanding of the system and enhance overall safety at sea, as communication is critical in foggy conditions.

Step 10. Document the Process

Finally, document the entire repair process for future reference. Detailed notes regarding the specific issues encountered, the steps taken, and any parts replaced can be invaluable when troubleshooting similar problems in the future.

Include pictures, as these can help illustrate complex assembly or disassembly steps. Keeping this information on hand can not only aid in resolving future problems but can also provide valuable insights for others who may face similar foghorn challenges.

By following these steps, you can effectively maintain and repair your foghorn system and ensure its reliable operation when needed most.

What are the Causes of a Malfunctioning Foghorn?

There are several potential reasons why a foghorn may malfunction, including:

- Dirt, Dust, or Debris Buildup: As mentioned earlier, obstructions in the system can significantly reduce sound output.

- Damaged or Worn-Out Parts: Over time, components of the foghorn may become damaged or wear out due to exposure to harsh marine environments.

- Air Supply Issues: Consistent and sufficient air pressure is crucial for proper operation. Any problems with the air supply, such as leaks or issues with the compressor, can affect the sound output.

- Electrical Faults: If your foghorn has electrical components, malfunctions can occur due to wiring issues or faulty connections.

- Misalignment during Reassembly: Improperly aligned parts during reassembly can result in operational issues.

Considering these potential causes is essential when troubleshooting any problems with your foghorn system.

5 Things You Should Avoid on how to fix foghorn pipes

- Using Incompatible Parts: Ensure any replacement parts are specifically designed for your foghorn model. Using incompatible components can result in further malfunctions and may void any warranties.

- Ignoring Manufacturer Instructions: Always refer to the manufacturer’s guidelines when repairing or maintaining your foghorn pipes. Disregarding these instructions can lead to improper assembly and potential damage to the system.

- Rushing the Process: Take your time to inspect and repair the pipes carefully. Rushing can lead to overlooked issues or improper installations, increasing the risk of future problems.

- Don’t Use Excessive Force: Avoid using excessive force when disassembling or reassembling the foghorn. This can damage delicate components further and require additional repairs.

- Use Any Tools Not Designed for Marine Environments: When working on a foghorn system, use high-quality tools specifically designed for marine environments. Using regular tools can result in rust or corrosion, affecting the longevity of your foghorn pipes.

By avoiding these mistakes, you can ensure a successful repair and maintain the integrity of your foghorn system for years to come.

Conclusion

In conclusion, how to fix foghorn pipes entails a combination of careful inspection, proper techniques, and ongoing maintenance practices.

By following the outlined steps—from disassembly and inspection to conducting functional tests and documenting your process—you can address common issues and ensure the reliable operation of your foghorn system.

Being mindful of potential causes of malfunction and avoiding common pitfalls during repairs will further contribute to the longevity of your equipment. Regular maintenance and a clear understanding among crew members about the foghorn system are vital for safety and efficiency.

These guidelines will better equip you to manage and maintain your foghorn pipes, ensuring they perform optimally when needed.