If you’re the proud homeowner of an older home, chances are you’ve encountered some plumbing problems. One especially pesky issue is finding a hole in your cast iron pipe – an intimidating repair without traditional methods or materials.

Thankfully, there are simpler and more cost-effective ways of repairing broken pipes and preventing future bursting episodes.

In this blog post, we will provide an easy-to-follow guide on how to fix hole in cast iron pipe plus bonus tips for avoiding further damage down the road! Keep reading and you’ll have your plumbing fixed up before you know it!

12 Step-by-step Guidelines on How to Fix Hole in Cast Iron Pipe

Step 1: Understand the Basics

Understand the basics of cast iron pipe repair and familiarize yourself with the tools you’ll need. It’s important to properly analyze the damage and determine the cause of the breakage before beginning any repair. You’ll need a hacksaw, flux paste, sandpaper or steel wool, and a torch. That said, safety first! Put on heat-resistant gloves and safety glasses.

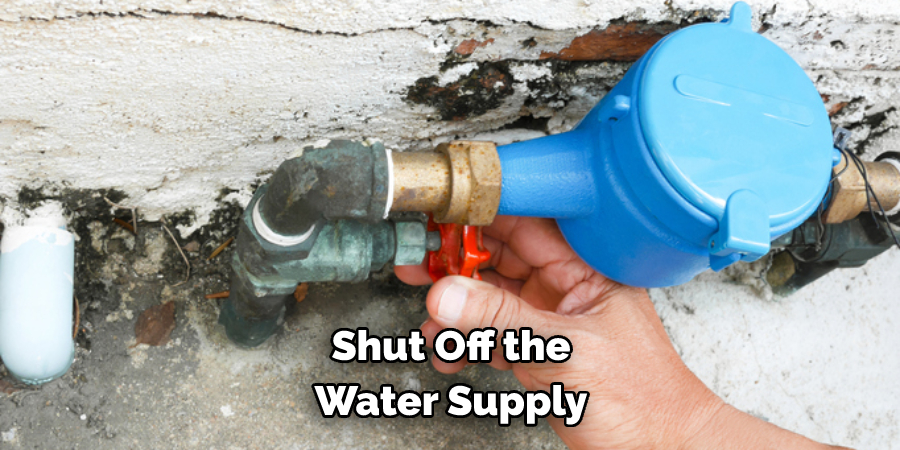

Step 2: Shut Off the Water Supply

Before attempting any repairs, it’s essential that you shut off the water supply to prevent further leakage or flooding. If you’re not sure which valves to shut off, take note of the location of your main water valve and turn it off. This will prevent any water from entering that part of the plumbing system. You should also take the time to turn off any appliances that are connected to this part of the plumbing system.

Step 3: Examine Pipe for Other Issues

Check the entire length of your cast iron pipe for any damages that may have occurred in other areas. It’s important to note this so you can properly address them during the repair process. This is also a good time to look for any corrosion or rust that may have accumulated. You may have to sand off any rust or corrosion residue before repairing the hole. It’s important to make sure that the pipe is clean before beginning any repairs.

Step 4: Remove the Pipe From the Wall or Floor

Carefully remove the affected pipe from where it is attached to the wall or floor, taking precautions not to cause extra damage. It is recommended that you use a hacksaw to cut away the pipe from where it attaches. You may also need to remove any nails or screws that are holding the pipe in place.

Step 5: Clean and Sandpipe Surface

Clean dirt, rust, and debris off of the surface before sanding down any rough edges or defects on your pipe. You can use steel wool or sandpaper to make sure any rough edges are smoothed out. This is an important step so that you can ensure a good seal. It is recommended to use 120-grit sandpaper for this step.

Step 6: Plug the Hole With Epoxy Putty

Apply epoxy putty directly over the hole, ensuring that the entire circumference is evenly covered. You may need to use your fingers or a putty knife to smooth out the epoxy and ensure a good seal. You’ll want to make sure that you don’t use too much, as this could cause the putty to ooze out of the sides and create a mess. That said, it’s important to also make sure that you have enough putty to completely cover the hole.

Step 7: Reinforce the Pipe With Mesh Tape

Apply mesh tape around the circumference of your pipe, making sure to overlap any existing seams or joints. After you’ve wrapped the tape around the circumference of your pipe, you can use a torch to melt and seal it in place. This will ensure a stronger and more reliable seal. It’s important to make sure that you don’t overheat the mesh, as this could cause damage to the pipe.

Step 8: Wrap Pipe with Fiberglass Cloth

Wrap a layer of fiberglass cloth around your pipe and secure it in place with metal banding straps or clamps. You may need to use a torch to melt the banding straps or clamps into place. This will help form an even stronger seal around the circumference of the pipe. You may need to use multiple layers of fiberglass cloth to ensure that the repair is secure.

Step 9: Caulk Perimeter of Hole

Fill any gaps between your epoxy putty and pipe surface with caulking material. This will provide an extra layer of protection against leaks. It’s important to make sure that you don’t overfill the gap, as this could lead to a messy repair. You may also need to use a utility knife or other sharp instrument to scrape away any excess caulking.

Step 10: Reattach Pipe to Wall or Floor

Carefully reattach your pipe to the wall or floor in its original position. Make sure all connections are securely fastened before turning the water back on. This is an important step that should not be skipped. You may need to use a wrench or screwdriver to tighten any connections. So make sure that you’ve got all the necessary tools on hand before beginning your repair.

Step 11: Check for Leaks

Turn the water supply back on and check for any leaks that may have occurred during the repair process. You can use a flashlight to check for any signs of dripping or wet spots. If you do find any leaks, then go back and make sure that all the connections are properly tightened and that all materials were securely applied. If everything looks good, you can move on to step 12!

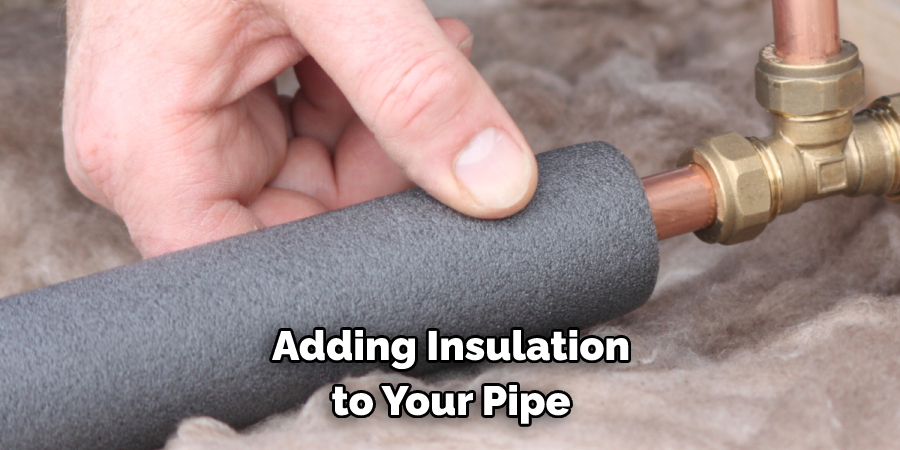

Step 12: Add Pipe Insulation

Adding insulation to your pipe will help keep it from freezing in cold temperatures and reduce noise levels. This is an optional step but highly recommended for homeowners with older pipes who live in a region with frequent temperature fluctuations.

After adding the insulation, be sure to inspect it periodically for any signs of wear and tear. So that’s it! You’ve successfully repaired your cast iron pipe and are ready to enjoy the benefits of a sturdy and reliable pipe system.

Following these steps should give you a better understanding on how to fix hole in cast iron pipe. And by following these instructions, you can avoid costly repairs in the future and maintain a durable plumbing system for years to come. With this guide and some determination, your cast iron pipe repair will be successful in no time!

Do You Need to Get Professional Assistance?

It can be difficult to repair cast iron pipes if you don’t have the right tools and knowledge. If you find yourself in such a situation, then it may be best to call a professional plumber. They will be able to assess the problem and provide an expert solution that should last for years to come.

It’s important to remember that cast iron pipes are extremely durable and can last for decades with proper upkeep. But if you find yourself in a situation where you need help, don’t hesitate to call in the professionals! They will be able to provide you with the best possible solution and ensure that your plumbing system stays healthy.

Frequently Asked Questions

Q: How Do I Know if My Pipe is Cast Iron?

A: You can easily identify a cast iron pipe by its weight, durability, and corrosion-resistant qualities. Cast iron pipes are also typically painted black and may have a sheen to them. If you’re still not sure, you can always consult a plumbing professional to double-check.

Q: What Tools Will I Need for the Repair?

A: You’ll need a few items to successfully repair your cast iron pipe, including epoxy putty and fiberglass cloth, a torch, caulking material, metal banding straps or clamps and pipe insulation (optional). You may also need some basic tools such as a wrench or screwdriver depending on the complexity of the repair.

Q: Are There Any Other Tips or Tricks to Keep in Mind?

A: Yes. It’s always a good idea to wear protective gloves and safety glasses while performing any kind of plumbing work, and it’s equally important to make sure that all the materials you use are rated for use with cast iron pipes. Finally, be sure to check for any signs of leaks after the repair is complete to ensure that your work was successful.

Q: Is it Necessary to Repair or Replace Cast Iron Pipes?

A: Yes, it’s important to repair or replace any damaged cast iron pipes in your home. If left untreated, these types of leaks can lead to costly water damage and other serious problems. So if you think you may have a hole in your cast iron pipe, it’s best to take action right away.

Conclusion

In conclusion, you now know how to fix hole in cast iron pipe. This task requires specific tools, adequate preparation, and close attention to detail. By following the steps outlined in this post we can guarantee that your repair job will last and your home will remain safe from water damage.

Never attempt this kind of work without doing thorough research or consulting with an expert in plumbing services. It is up to each homeowner to take responsibility for their own safety and success when attempting a job like this.

Cast iron pipes are notoriously difficult to repair but with the right preparation, the proper materials, and some focus it can be done successfully. We hope you have gained enough knowledge from reading this post so you feel confident in tackling this project on your own!