A well-functioning furnace ignition system is essential for maintaining a comfortable and safe environment in your home, particularly during the colder months. The ignition system serves as the heart of your furnace, responsible for initiating the heating cycle that warms your living space. However, furnaces are equipped with a critical safety feature known as an ignition lockout.

This feature automatically shuts down the furnace after several unsuccessful ignition attempts, preventing potential damage or dangerous gas buildup. Understanding the cause of an ignition lockout is crucial before attempting any fix.

An ignition lockout can occur due to various reasons, including issues with the fuel supply, faulty ignition components, or a clogged air filter. Knowing “how to fix ignition lockout on furnace” not only helps in restoring warmth and comfort to your home but also ensures the safety and efficiency of your heating system.

This guide aims to provide homeowners with a comprehensive understanding of the furnace ignition system, the significance of ignition lockout, and the preliminary steps to diagnose and address this issue.

The Furnace Ignition Process

The furnace ignition process is a critical cycle that begins when the home’s thermostat detects a need for increased heat, signaling a heating demand. This demand triggers the furnace to start its ignition sequence, a precise and coordinated series of events designed to safely and efficiently produce heat.

The first major step in this process involves the opening of the gas valve, a mechanism that controls the flow of gas (natural gas or propane) to the furnace’s burners. It’s at this point that the igniter, either a glow bar or a spark igniter, plays its crucial role.

For systems using a glow bar, this component heats up to a specific temperature capable of igniting the gas. In contrast, in systems relying on a spark igniter, an electrical spark is generated to start the combustion process. Following successful ignition, the flame sensor comes into play.

This sensor has the vital job of detecting the presence of the flame, ensuring that combustion has indeed commenced. Once the flame sensor verifies the presence of a flame, it sends a confirmatory signal to the furnace’s control board.

In response to this signal, the control board executes the next critical action—it keeps the gas valve open, allowing gas to continue flowing into the burners to maintain combustion. This ongoing flow sustains the flame, ensuring that the furnace can meet the heating demand signaled by the thermostat.

Thus, through a carefully regulated process involving several key components and precise timing, the furnace ignition cycle efficiently generates and maintains heat, adhering to the demand for warmth dictated by the home’s thermostat. This sequence highlights the intricacies and safety measures inherent in modern furnace operations, underscoring the importance of each component’s functionality in achieving efficient and safe heating.

Causes of Furnace Ignition Lockout

Ignition lockouts in furnaces can stem from an array of issues, predominantly involving the system’s key components, such as the igniter and flame sensor, or operational hindrances, like clogged burners or airflow problems.

A Faulty Igniter is one of the primary culprits behind ignition lockout. The igniter, responsible for initiating the combustion process, can fail due to wear over time, leading to insufficient heating or failure to spark. This inadequacy in reaching the necessary temperature or producing a spark prevents the gas from igniting, prompting the system to enter a lockout mode for safety.

Flame Sensor Issues further contribute to lockouts. The flame sensor’s role in verifying the presence of a flame is critical. If this sensor becomes dirty or is damaged, it may inaccurately fail to detect a flame even when the gas is ignited, leading to an unnecessary lockout. Regular cleaning and maintenance can mitigate this issue, ensuring the sensor accurately performs its safety function.

Clogged Burner Assembly, caused by an accumulation of dust or debris, can also obstruct gas flow, making it difficult to maintain or even initiate a flame. This obstruction not only impedes proper ignition but can also lead to a gas buildup, triggering a lockout to prevent potential hazards.

Airflow Problems play a significant role in furnace ignition issues. A furnace requires a consistent flow of air for combustion and to expel exhaust gases. A dirty air filter or a clogged flue can significantly restrict this airflow, impacting the furnace’s ability to ignite properly. These issues can cause the system to overheat or fail to maintain an adequate combustion process, leading to lockout situations.

Lastly, Safety Controls, such as limit switches, are designed to monitor the furnace’s operation for abnormal conditions, such as overheating components or venting issues. If these controls detect circumstances that could lead to unsafe operating conditions, they may trigger a lockout to prevent further operation until the underlying problem is addressed.

Understanding these common causes of ignition lockout not only aids in diagnosing the issue but also underscores the importance of regular maintenance and professional inspection to ensure the safe and efficient operation of the furnace system.

Signs of Furnace Ignition Lockout

Recognizing the signs of an ignition lockout can help homeowners identify and address furnace issues before they escalate. One of the most apparent symptoms is the Furnace Failing to Ignite Repeatedly After Thermostat Activation.

When the thermostat signals for heat, but the furnace does not respond with the expected ignition sequence, it often indicates a lockout condition. Homeowners may also notice Short Bursts of Ignition Attempts Followed by a Shutdown. This scenario happens when the furnace attempts to ignite but quickly shuts off due to failing one of the initial steps in the ignition process.

Another clear sign of trouble is an Error Code Displayed on the Furnace Control Panel. Modern furnaces are equipped with diagnostic systems that display specific error codes to signal various issues, including ignition lockout. Referencing the furnace manual can help decipher these codes and pinpoint the problem.

Lastly, for furnaces that still use a pilot light, if the Pilot Light Won’t Stay Lit, it can signify an ignition lockout issue, especially if repeated attempts to relight it fail. Monitoring these signs closely can lead to quicker diagnoses and solutions, ensuring that your home remains warm and safe during colder months.

Safety Precautions Before Troubleshooting

Before attempting to troubleshoot or repair any issues with the furnace, particularly in cases of an ignition lockout, it is crucial to adhere to stringent safety precautions to avoid personal harm or further damage to the system. The primary step involves Turning Off the Furnace at both the thermostat and the breaker.

This procedure ensures that the system is completely powered down, eliminating the risk of electrical shock or accidental ignition during the troubleshooting process. It is advisable to Wait at Least 5 Minutes after shutting off the power to allow any residual heat within the furnace components to dissipate, reducing the risk of burns upon contact.

Equally important is the need to Work in a Well-Ventilated Area. Furnaces, by their nature, involve combustion processes that can release harmful gases. Ensuring proper ventilation is essential to avoid the accumulation of gas fumes, which can be hazardous to health. This is particularly critical when inspecting or cleaning the burner assembly, where gas residue may still be present even after the system is shut off.

Personal protective equipment (PPE) plays a substantial role in ensuring safety during furnace maintenance. Wearing Gloves and Safety Glasses is recommended to protect against sharp edges within the furnace’s interior and any dust or debris that might be dislodged during troubleshooting. Protective eyewear is especially vital to prevent injury from flying particles or accidental splashes from cleaning agents used on the components.

While these precautions provide a basis for safer troubleshooting, the complexity of furnace systems should not be underestimated. Therefore, it is Strongly Recommended to Consult a Qualified HVAC Professional if you are uncomfortable or inexperienced with furnace troubleshooting and repairs.

Professional technicians possess the knowledge, tools, and experience to diagnose and resolve issues safely and efficiently. They are also familiar with the latest safety standards and procedures, ensuring that any repairs or maintenance work carried out adheres to these guidelines.

In summary, it cannot be overemphasized that you should prioritize safety before initiating any troubleshooting steps on your furnace. Critical measures include turning off the furnace, waiting for residual heat to dissipate, ensuring proper ventilation, and using personal protective equipment. However, when in doubt, seeking assistance from a professional not only ensures your safety but also the operational integrity of your heating system.

How to Fix Ignition Lockout on Furnace: Basic Troubleshooting Steps

A. Resetting the Furnace

Resetting your furnace can often address temporary glitches or errors in its operation. To reset, locate the reset button on your furnace—this may vary by model, so refer to your owner’s manual if necessary. Press the reset button once; pressing it multiple times can further confuse the system.

A successful reset clears existing faults and can restore normal functioning. If the furnace does not resume operation or re-enters lockout mode, this indicates a more profound issue necessitating professional inspection.

B. Checking the Thermostat

The thermostat is the command center for your furnace, so it’s crucial to ensure it’s properly set. First, ensure the thermostat is switched to “heat” mode. Then, set the temperature a few degrees higher than the current room temperature to initiate a heating cycle.

Also, check for any low battery warnings, as a weak battery can impair thermostat performance. If your thermostat is programmable, verify it’s not set to a schedule that prevents heating during desired times.

C. Inspecting the Air Filter

A clogged or dirty air filter is a common culprit behind furnace operation issues, including ignition lockout. Inspect the filter for excessive dirt buildup. If the filter appears dirty, replace it with a new one to ensure unobstructed airflow. A clean air filter not only facilitates efficient combustion and system operation but also improves indoor air quality.

To prevent future furnace problems and maintain optimal efficiency, establish a regular schedule for changing the air filter, typically every three months or as recommended by the manufacturer.

How to Fix Ignition Lockout on Furnace: Advanced Troubleshooting

Advanced troubleshooting steps can help identify and potentially resolve more intricate issues causing a furnace ignition lockout. However, these steps require careful handling to avoid damaging the furnace components or compromising safety.

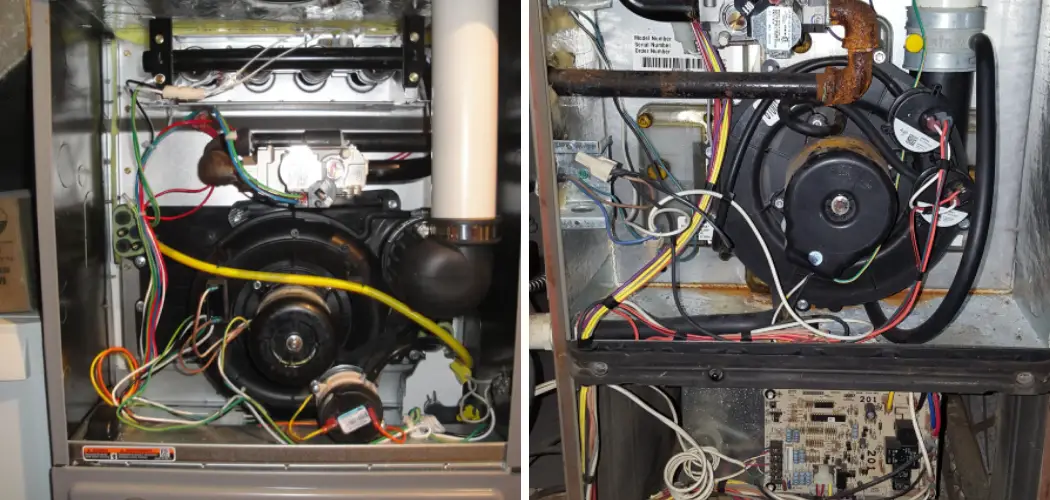

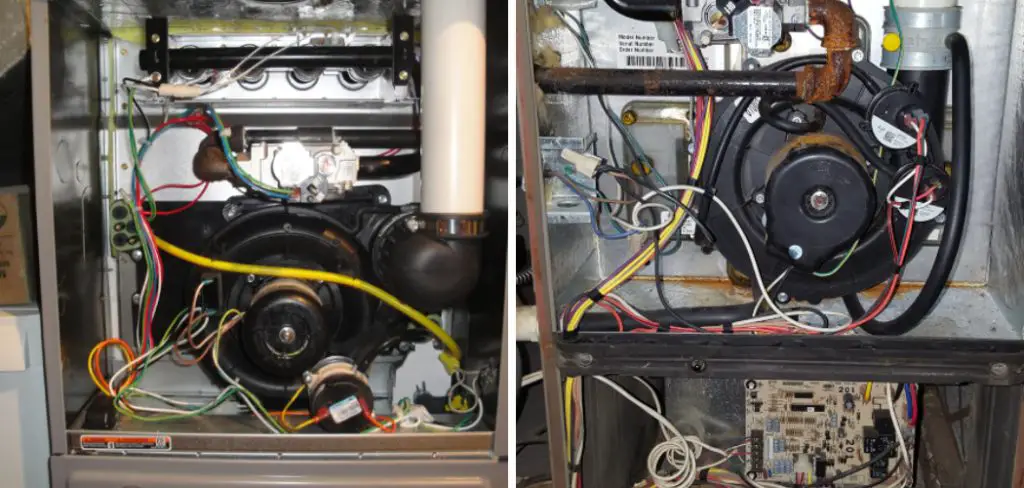

A. Visually Inspecting Components

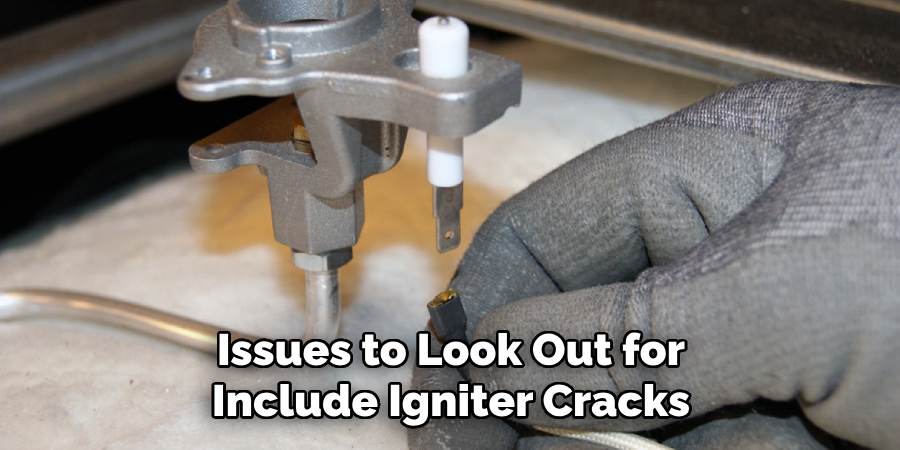

Begin by visually inspecting the igniter, flame sensor, and burner assembly for any obvious signs of wear or damage. Common issues to look out for include igniter cracks, flame sensor corrosion, and excessive debris or dust buildup around the burner assembly.

Loose connections or wiring can also contribute to ignition problems. While a visual inspection might not catch all issues, identifying and correcting obvious physical damage is a crucial step in troubleshooting. Always ensure the furnace is powered off and has cooled down before performing any inspections.

B. Cleaning the Flame Sensor

A dirty flame sensor can prevent the furnace from igniting by failing to detect the flame properly, which leads to a safety shutdown. The flame sensor is usually located near the burner assembly, but its exact position varies by furnace model—consult your manual for specifics.

To clean the flame sensor, first, ensure the furnace is powered off and has cooled completely. Gently clean the sensor with a soft, dry cloth or use compressed air to remove dust and debris. Avoid using water, household cleaners, or abrasive materials, as these can damage the sensor.

C. Resetting High Limit Switch (if accessible)

Some furnaces are equipped with a high-limit switch, which triggers a lockout to prevent overheating. If your furnace has a high-limit switch with a manual reset button (check your manual for details), and you feel comfortable doing so, you can try to reset it. However, be cautious—repeated activations of the high-limit switch indicate a more severe issue, such as restricted airflow or a malfunctioning blower motor, that requires professional evaluation.

D. Importance of Consulting a Professional

While these advanced troubleshooting steps can address specific furnace lockout issues, they are not comprehensive solutions for all problems. Persistent furnace lockouts after attempting these measures indicate a deeper, potentially complex issue that merits professional diagnosis and repair.

A qualified HVAC professional has the tools, skills, and experience necessary to safely and effectively restore your furnace to optimal working conditions, ensuring both efficiency and safety.

Preventing Future Ignition Lockouts

To mitigate the risk of further ignition lockouts and to maintain the furnace in optimal condition, the importance of regular maintenance by a qualified professional cannot be overstressed. Such preventative care serves not only to identify and rectify potential issues before they escalate into more significant problems but also to ensure the furnace operates at peak efficiency.

It is recommended that homeowners schedule annual maintenance checks, preferably before the onset of the heating season. During these checks, professionals will conduct thorough cleaning, inspect various components for wear or damage, and make necessary system adjustments.

Regular filter changes, conducted every 1 to 3 months, depending on usage and the environment, are a simple yet effective way to maintain optimal airflow and prevent dust buildup. A clean air filter supports efficient furnace operation and contributes to healthier indoor air quality.

In addition to changing the air filter, attention should be paid to any signs of limited airflow, such as clogged flues or dirty vents. Restricted airflow can significantly affect furnace performance, increasing the likelihood of ignition lockouts. Addressing these elements not only prevents potential future ignition issues but also extends the life of the furnace, enhancing home comfort and safety.

By committing to regular furnace maintenance and addressing aspects like air filter changes and airflow restrictions, homeowners can significantly reduce the incidence of furnace ignition lockouts. More importantly, these preventative measures contribute to a safer, more energy-efficient home heating system.

Conclusion

In conclusion, understanding how to fix ignition lockout on furnace involves recognizing the potential causes—ranging from simple issues like a tripped circuit breaker or dead thermostat battery to more complex problems such as a dirty air filter or a malfunctioning flame sensor.

Through systematic troubleshooting steps, homeowners can address some of these issues independently, such as checking power sources, inspecting and replacing the air filter, and cleaning the flame sensor. However, safety should always be the paramount concern. Powering off the furnace and ensuring it has cooled before attempting any inspection or maintenance is crucial.

Consulting a professional is imperative for issues that surpass basic troubleshooting or when in doubt. Not only does this safeguard against incorrect handling that could exacerbate the problem, but it also ensures that repairs are conducted safely and effectively.

Furthermore, the benefits of preventative maintenance, including regular filter changes, cannot be overstated. Such proactive steps significantly reduce the risk of furnace ignition lockouts by maintaining optimal airflow and preventing dust buildup, ensuring the furnace operates reliably and efficiently.

Ultimately, a commitment to regular maintenance and a cautious approach to troubleshooting can enhance furnace longevity, performance, and safety, offering peace of mind to homeowners throughout the heating season.