Leaking pipes can be a nuisance and costly issue to repair. Threaded joints are often the culprits of leaks, but they can be tricky to fix due to the difficulty of disassembling them. Fortunately, there is a way to fix leaking threaded joints without disassembly. This method is not only effective but also saves time and money.

There are several advantages when fixing a leaking threaded joint without disassembly. One is that it saves time and labor, as the repair can be done without disassembling the joint completely. Another advantage is that it may cost less than replacing the entire joint altogether since only minimal repairs would need to be made.

It also eliminates the possibility of introducing additional leaks into the system since no new parts need to be added. You can find step-by-step instructions on how to fix leaking threaded joint without disassembly in this blog article.

Tools You Will Need

- Pipe wrench

- Teflon tape

- Pipe sealant

- Brush or rag (to clean the threads)

- Hammer

- Hacksaw or reciprocating saw

- Thread chaser

- Plumber’s putty knife

- Torch or heat gun

- Flashlight for inspecting area closely.

Step by Step Processes for How to Fix Leaking Threaded Joint Without Disassembly

Step 1: Inspect the Leaking Joint

Carefully check the area around the leaking joint to identify any damage that may be causing the leak. Look for corrosion, dirt and debris, or excessive wear of the threads. If you notice any significant damage, disassemble and repair the joint before proceeding with this method.

Step 2: Clean the Threads

Use a small brush and a cleaning solvent to remove any dirt or debris from the threads. Be sure to use only products that are designed for cleaning threaded joints, as some solvents can damage the threads. Apply a small amount of tightening compound to the threads at the leaking joint. This will help to create a seal and reduce the possibility of future leaks.

Step 3: Tighten Joint

Tighten the joint with a wrench or adjustable wrench until it is snug but not overly tight. Over-tightening can damage the threads, resulting in a leaky joint. At least once a year, retighten the joint to ensure that it is still leak-free. This will help keep the seal in place and prevent any future leaks.

Step 4: Check for Leaks

Once you have tightened the joint, turn on the water or other fluid and check for any leaks. If you find any, apply more tightening compound and retighten the joint. If you still have problems with leaks, try applying a pipe dope to the threads at the leaking joint before retightening it. This will help create an even stronger seal and prevent future leaks.

Step 5: Monitor Leaks

Once you have fixed the leak, monitor it for a few months to make sure that it stays sealed. Retighten the joint or replace the pipe if you notice any new leaks. Apply lubricants such as grease or oil to the threads at least once a year to help prevent future leaks.

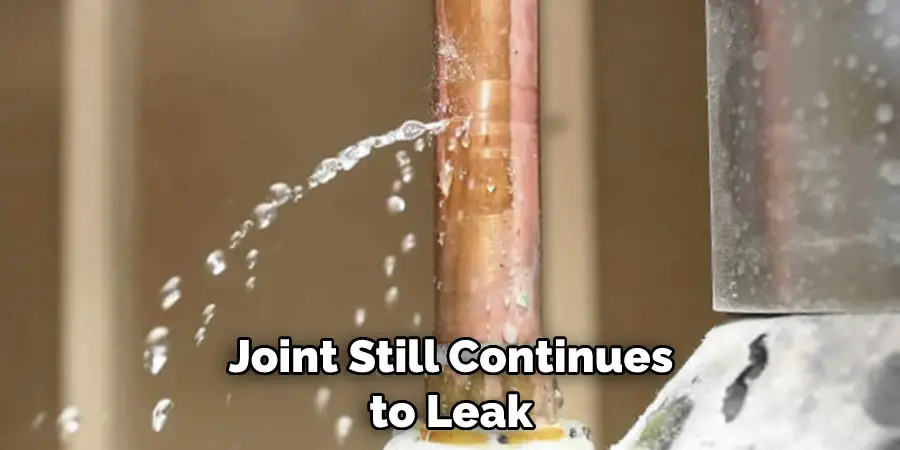

Step 6: Repair or Replace Joint as Needed

If the joint still continues to leak, it may be time to repair or replace it. If you are unable to fix the leak using this method, contact a professional plumber for assistance. This is especially important if the joint is corroded or damaged beyond repair.

By following these simple steps, you can fix a leaking threaded joint without disassembly and maintain a secure seal for years to come. However, if the leak persists after trying this method, it may be time to contact a professional plumber for assistance.

Tips for How to Fix Leaking Threaded Joint Without Disassembly

- Always use personal protective equipment when working with hazardous substances, such as gloves and goggles.

- Check the joint for any loose fittings that may have come undone due to over-tightening or wear and tear.

- Use a cloth or rag to clean off any dirt, debris, and corrosion from the joint.

- Use a thread sealant to ensure that the joint is securely sealed and that no air or water can enter through it.

- Check that there are no open valves in your working area, as this could cause pressure to build up inside your system and create leaks.

- Test the joint before reassembling it by pressurizing it or running a flow test.

- Always tighten the joint in a clockwise direction, as this will prevent further damage to the threads and ensure that the seal is secure.

Following these steps can help you successfully fix leaking threaded joints without disassembly. It is important to remember always to wear safety equipment and use only quality materials when working with any type of machinery, as failure to do so can lead to serious injury.

Is There an Easy Way to Identify the Source of the Leak?

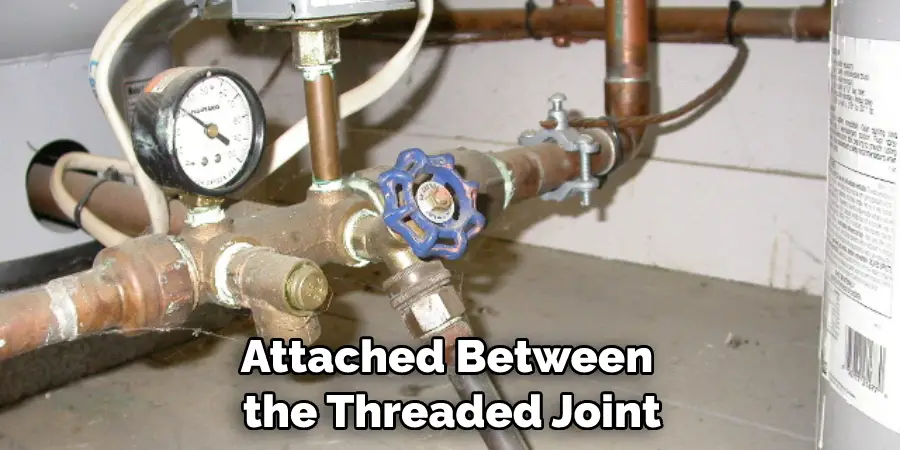

The first step in repairing a leaking threaded joint without disassembly is to identify the source of the leak. This can be done by using an oil pressure gauge and a lighted magnifying glass or flashlight. The pressure gauge should be attached between the threaded joint and its mating surface, while the magnifying glass/flashlight should be used to inspect the area around the joint for any signs of leakage.

If there is no visible sign of leakage, then the source of the leak may be due to a thread sealant that has been applied incorrectly or is inadequate for use in high-pressure applications.

Another way to identify the source of the leak is by using an ultrasonic flow meter to measure the flow rate through the joint. This will allow you to determine if there is a decrease in pressure or flow as a result of the leak. If so, then the source of the leak can be identified and addressed accordingly.

How Can You Prevent Leaks in Threaded Joints Before They Occur in the Future?

The best way to prevent future leaks from threaded joints is to ensure that they are properly assembled. This means creating a tight seal between the two parts and using the correct amount of sealing material (such as Teflon tape or pipe dope). It also means taking extra care when tightening the joint, as over-tightening can cause damage, leading to leaks.

If possible, it is also beneficial to check the joint for any signs of wear or damage before assembly. If any parts appear worn or damaged, they should be replaced with new ones to avoid any potential issues down the line. Additionally, if there are any crevices around the joint, it may be beneficial to apply a sealant to help protect against water ingress.

Finally, it is important to make sure that any connecting parts are from compatible materials. If the materials are incompatible, then they may react with each other and cause leaks.

How Can You Tell if the Repair Was Successful or Not?

Once the repair has been completed, it’s important to monitor the joint and make sure that the leak is stopped. To do this, you can use a pressure gauge or test analyzer to measure the pressure of the liquid inside the threaded joint. You should also inspect the area around the joint for any signs of leakage.

If you find that the repair was unsuccessful, you will need to disassemble the joint and check for any defects or damage that may be preventing a good seal. In some cases, replacing components such as gaskets or O-rings may be necessary to ensure a leak-proof seal.

It’s important to note that the repair may not be a permanent solution, and you may need to check the joint periodically for signs of leakage. Regular maintenance and inspection can help prevent future leaks from occurring in threaded joints.

What Are Some of the Common Causes of Leaking Threaded Joints?

Several factors can lead to leaking threaded joints, such as poor surface preparation, improper thread fit, or inadequate tightening torques. Poorly machined threads, dirt and debris in the threads, corrosion, or chemical attack on the parts are also common causes. Other factors include using inferior sealing materials, over-torquing, or using inadequate thread-locking compounds.

The threads must fit properly and be cleaned before assembly to prevent a leaking threaded joint. The sealing material should also be of good quality and applied correctly. Thread lubricants and thread-locking compounds should also be used as necessary to ensure a tight seal. Proper tightening torque must also be followed when assembling the joint.

Conclusion

In conclusion, fixing a leaking threaded joint without disassembly is possible if you have the right tools and knowledge. It requires careful application of sealant to all areas that could contribute to a leak, ensuring that all are completely sealed. You must also be aware of any potential safety issues, such as sharp edges or questionable materials used in the construction of the joint.

With the proper precautions taken and attention to detail, you can easily fix a leaking threaded joint without disassembly. I hope this article has been beneficial for learning how to fix leaking threaded joint without disassembly. Make Sure the precautionary measures are followed chronologically.