A pipe thawing machine is an essential tool for addressing frozen pipes, especially during harsh winter months. It works by using electrical currents to safely and efficiently melt the ice within the pipes, restoring water flow and preventing potential damage. Proper maintenance and troubleshooting of the machine are crucial to ensure it operates effectively when needed.

This guide on how to fix pipe thawing machine will walk you through the steps to identify common issues and fix your pipe thawing machine.

Why is It Important to Fix Pipe Thawing Machine?

A malfunctioning pipe thawing machine can lead to significant damage to your pipes and water system. If the frozen pipes are not addressed promptly, they may burst, causing flooding and costly repairs.

Additionally, a faulty machine can also pose safety hazards, such as electrical shocks or fires. Therefore, it is crucial to address any issues with your pipe-thawing machine promptly.

Needed Materials

- Insulated Gloves

- Multimeter (to Test Electrical Connections)

- Wrenches or Pliers (for Tightening Loose Connections)

- Replacement Parts, if Necessary

8 Step-by-step Guidelines on How to Fix Pipe Thawing Machine

Step 1: Check the Power Supply

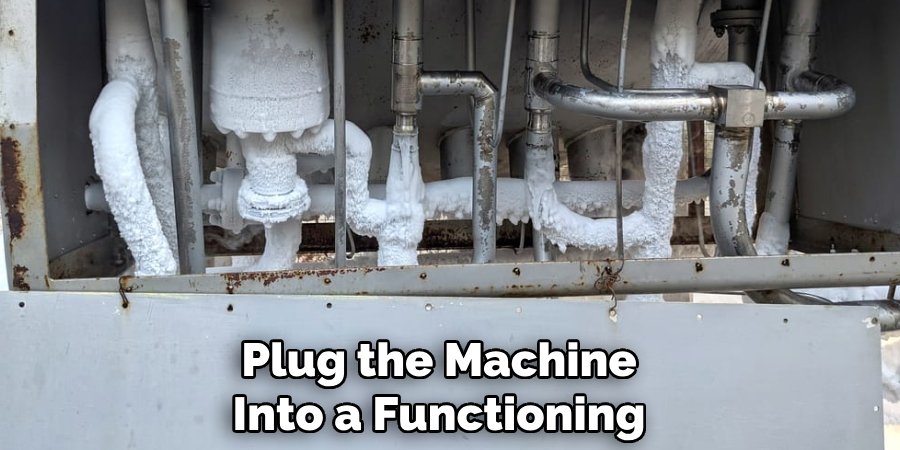

The first step in fixing your pipe thawing machine is to verify that it is receiving the proper power supply. Begin by inspecting the power cord for any visible damage, such as fraying or exposed wires that could interrupt the electrical connection.

Plug the machine into a functioning outlet and make sure the outlet is providing power by testing it with another device, such as a lamp or phone charger. If the outlet is not working, check your circuit breaker to ensure it hasn’t tripped. A stable and uninterrupted power supply is essential for the machine’s operation, so addressing any issues at this stage can often resolve simple power-related problems.

Step 2: Inspect the Thermostat

The thermostat is a critical component in regulating the temperature of the pipe-thawing machine. Begin by turning off the machine and unplugging it to ensure safety. Remove any protective covering to access the thermostat. Check for any visible signs of damage, such as cracks, corrosion, or loose wires. A multimeter is used to test the thermostat’s functionality by measuring continuity.

If the thermostat fails the test or exhibits signs of wear, it may need to be recalibrated or replaced. A properly functioning thermostat ensures the machine operates at the correct temperature, preventing overheating or inefficiency during the thawing process.

Step 3: Check the Heating Element

The heating element is responsible for generating the heat that thaws the frozen pipes. Inspect the element for any visible damage, such as breaks or burn marks. A multimeter is used to test its functionality by measuring continuity.

If there is no continuity, it may indicate a damaged or broken heating element that needs replacement. A faulty heating element will prevent the machine from effectively thawing pipes, so addressing any issues with it is crucial.

Step 4: Clean or Replace the Nozzles

Nozzles play an essential role in directing heat accurately during the thawing process. Over time, they can become clogged with debris or suffer wear and tear, reducing their effectiveness. Start by turning off and unplugging the machine for safety. Remove the nozzles carefully and inspect them for signs of blockage, rust, or damage.

Use a brush or compressed air to clean out any debris and ensure the nozzles are clear. If the nozzles are damaged or overly worn, replace them with compatible parts. Properly functioning nozzles are vital for ensuring efficient heat transfer and avoiding any uneven thawing of the pipes.

Step 5: Check for Loose Connections

Loose connections can also cause issues with the pipe-thawing machine. Inspect all electrical connections, including those to the thermostat and heating element, for any visible signs of looseness or corrosion. Using wrenches or pliers, tighten any loose connections to ensure a secure and safe connection.

You may also want to consider using electrical tape to secure any wires or connections that appear frayed or exposed. Loose connections can lead to inefficient operation and potential safety hazards, so addressing them is crucial.

Step 6: Test the GFCI Outlet

A ground fault circuit interrupter (GFCI) outlet is a safety feature designed to protect against electrical shocks. If your pipe thawing machine is not working correctly, check if it is plugged into a GFCI outlet. Press the “test” button on the outlet, and if it pops out, press the “reset” button to restore power. If this does not resolve the issue, try plugging the machine into a non-GFCI outlet to see if it operates correctly.

If the machine works when plugged into a non-GFCI outlet, there may be an issue with the GFCI outlet that needs to be addressed. Working with electricity can be dangerous, so if you are unsure or uncomfortable with this step, consider seeking professional help.

Step 7: Look for Signs of Damage on the Machine

Inspect the overall condition of your pipe thawing machine for any visible signs of damage or wear and tear. This could include cracks, rust, or loose parts. If you notice any issues, address them promptly by cleaning, repairing, or replacing damaged parts as needed. Proper maintenance can extend the lifespan of your machine and ensure its safe operation.

It is also essential to regularly clean your pipe thawing machine, especially after use, to remove any debris or build-up that could affect its functionality. Refer to the manufacturer’s instructions for specific cleaning recommendations.

Step 8: Seek Professional Help if Needed

If you have followed all the previous steps and are still unable to fix your pipe thawing machine, it may be time to seek professional help. A qualified technician can diagnose and address more complex issues with your machine that may require specialized knowledge and tools.

Make sure to provide the technician with information about any steps you have already taken, including any tests or inspections you have performed. This can help them narrow down potential problems and find a solution more quickly.

By following these step-by-step guidelines on how to fix pipe thawing machine, you can troubleshoot and address common issues that may arise with your machine, saving time and potentially costly repairs in the future. Regular maintenance and proper care can also ensure your pipe thawing machine operates efficiently and effectively whenever needed.

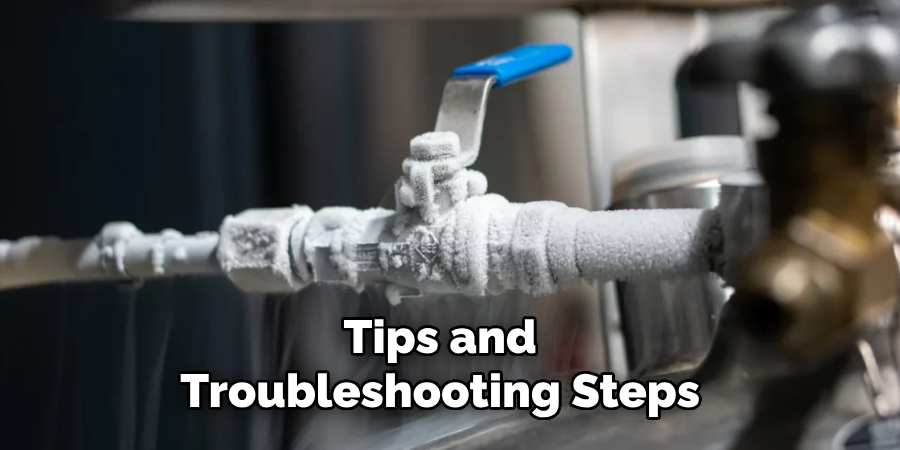

Troubleshooting Common Issues

Here are some of the most common issues you may encounter with your pipe thawing machine and how to fix them:

No Power:

The first step in troubleshooting any electrical appliance is checking if it has power. Ensure that the power cord is plugged in and the outlet is functioning correctly. If the machine still does not turn on, refer to Step 6 for troubleshooting a GFCI outlet or check the fuse box for any tripped circuits.

Machine Not Thawing Pipes:

If your pipe thawing machine appears to be running but is not thawing pipes effectively, there may be an issue with the thermostat or heating element. Refer to Steps 2 and 3 for inspecting and testing these components. Additionally, make sure that you are using the correct settings and allowing enough time for the machine to heat up.

Uneven Thawing:

Uneven thawing can occur if there are clogs in the nozzles, damaged nozzles, or if the machine is not positioned correctly. Refer to Step 4 for cleaning or replacing nozzles and ensure that they are properly aligned with the frozen pipes.

Machine Overheating:

An overheated pipe thawing machine can be a safety hazard and may indicate an issue with the heating element or thermostat. Refer to Steps 2 and 3 to check these components. Make sure to also follow the manufacturer’s instructions regarding operating temperatures and duration of use.

Strange Noises or Smells:

If your machine is making unusual noises or emitting strange smells, turn it off immediately and unplug it for safety reasons. Inspect the machine for any signs of damage or overheating, and refer to Step 8 for seeking professional help if needed.

Additional Tips for Maintaining Your Pipe Thawing Machine

- Store your machine in a dry and clean location when not in use.

- Regularly inspect the power cord for any visible damage and replace it if necessary.

- Keep the nozzles clean and free of debris to ensure efficient heat transfer.

- If using extension cords, make sure they are rated for the machine’s power requirements.

- Follow the manufacturer’s instructions for proper operation and maintenance to avoid potential issues.

By following these tips and troubleshooting steps, you can ensure your pipe thawing machine is always ready for use when needed. Remember to prioritize safety and seek professional help if any concerns arise that you are not comfortable addressing yourself. Regular maintenance and care can prevent unexpected breakdowns and keep your machine in top working condition for years to come.

Conclusion

Proper maintenance and timely troubleshooting are essential to keep your pipe thawing machine functioning safely and effectively. By following the step-by-step guidelines on how to fix pipe thawing machine provided in this document, along with the additional tips for care and upkeep, you can address common issues and prevent potential problems before they arise. Remember that safety should always be your top priority.

If you encounter any complex or unfamiliar issues, do not hesitate to seek professional assistance. With regular maintenance and attention to detail, your pipe thawing machine will remain a reliable tool for managing frozen pipes and ensuring smooth operation during cold weather.