When troubleshooting heating systems, one common issue that homeowners and technicians may encounter is a pressure switch that remains open while the inducer motor is running. This problem can prevent the heating system from igniting, leading to discomfort in the home and potential damage to the system.

Understanding the role of the pressure switch and the inducer motor is crucial for effectively diagnosing and resolving this issue. In this guide, we will explore how to fix pressure switch open with inducer on, as well as actionable steps to fix the problem and restore proper functionality to your heating system.

Understanding Pressure Switch Open with Inducer On

The pressure switch is a vital component in a heating system, designed to monitor the airflow created by the inducer motor. When the inducer is operational, it generates negative pressure within the vent system, allowing the pressure switch to close and enable fuel to flow to the burner. However, if the pressure switch remains open despite the inducer running, it indicates that the system isn’t detecting adequate airflow.

This can occur due to various reasons, including blockages in the venting system, a malfunctioning inducer motor, or faulty wiring. Identifying the root cause of this issue is essential, as it can lead to system inefficiency, safety concerns, and expensive repairs if not addressed promptly. Understanding the interaction between these two components lays the groundwork for effective troubleshooting and repair.

10 Methods How to Fix Pressure Switch Open with Inducer on

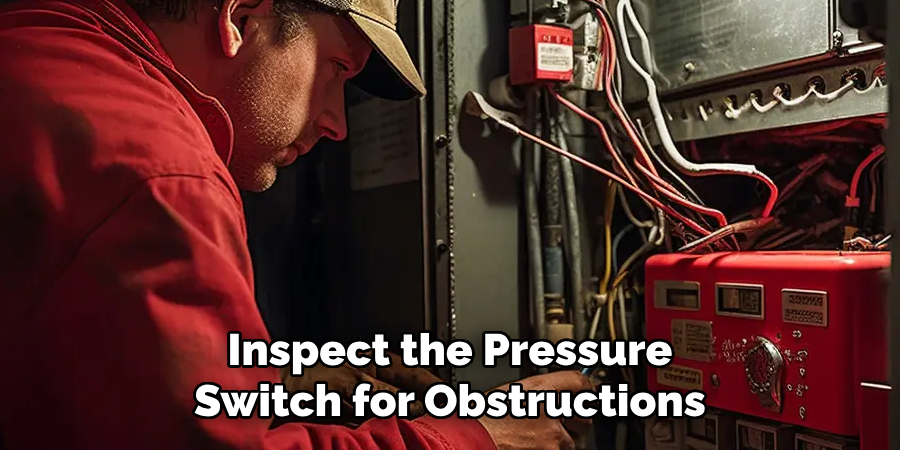

1. Inspect the Pressure Switch for Obstructions

The first step in addressing a pressure switch open condition is to inspect the pressure switch itself for any obstructions or debris. The pressure switch is designed to detect changes in pressure and should be free of any physical blockages.

Turn off the power to the furnace to ensure safety, then locate the pressure switch, which is usually mounted near the inducer fan. Check for any dirt, dust, or obstructions around the switch and clean it gently with a soft brush or compressed air. Removing any debris ensures that the pressure switch can operate correctly and accurately.

2. Verify the Pressure Switch Tubing

The pressure switch is connected to the furnace through a small rubber or plastic tubing that transmits pressure readings. If this tubing becomes clogged, damaged, or disconnected, it can lead to an open pressure switch condition. Inspect the tubing for any signs of wear, cracks, or blockages. Ensure that the tubing is securely connected to both the pressure switch and the inducer fan. If you find any issues, replace the tubing or make the necessary repairs to restore proper pressure sensing and eliminate the open switch condition.

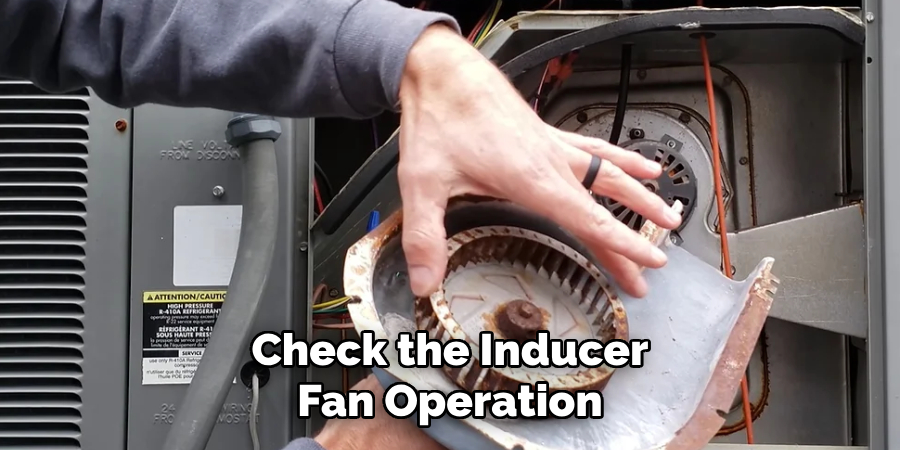

3. Check the Inducer Fan Operation

The inducer fan plays a crucial role in creating the proper airflow and pressure within the furnace. If the inducer fan is not functioning correctly, it can lead to a pressure switch open condition. Turn on the furnace and listen to the inducer fan to ensure it is operating smoothly and quietly.

Check for any unusual noises or vibrations that may indicate a problem with the fan. If the inducer fan is not working properly, inspect it for any obstructions or mechanical issues and replace or repair it as needed to restore proper operation and pressure.

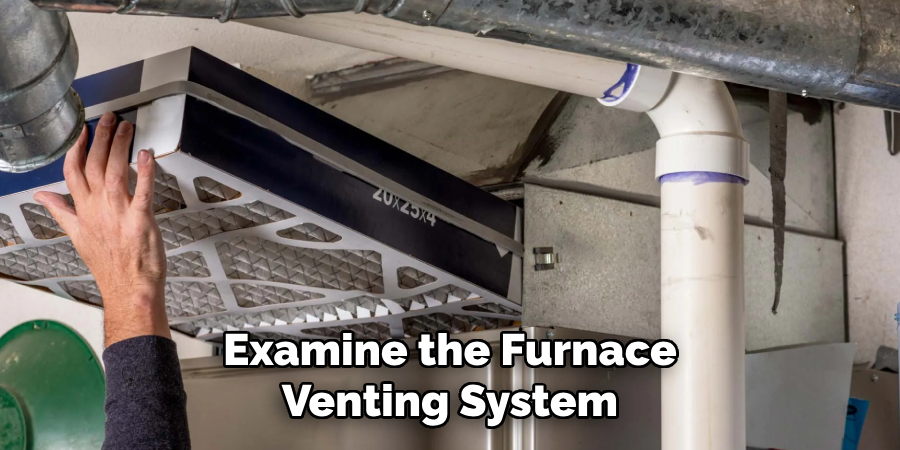

4. Examine the Furnace Venting System

A blockage or restriction in the furnace venting system can affect the pressure within the furnace and lead to an open pressure switch condition. Inspect the venting system, including the flue pipe and vent stack, for any signs of blockage or debris.

Ensure that the venting system is clear and unobstructed to allow for proper airflow and exhaust. If you find any blockages, remove them carefully and ensure that the venting system is functioning correctly. Proper venting is essential for maintaining the correct pressure and preventing open switch conditions.

5. Test the Pressure Switch for Continuity

Testing the pressure switch for continuity can help determine whether it is functioning properly. Use a multimeter to check the continuity of the pressure switch. With the furnace turned off, disconnect the wires from the pressure switch terminals and set the multimeter to the continuity setting.

Place the probes on the terminals and check for a reading. If the multimeter shows no continuity, the pressure switch may be faulty and need to be replaced. Testing the pressure switch helps ensure that it is operating correctly and accurately sensing pressure changes.

6. Inspect the Furnace’s Draft Inducer Motor

The draft inducer motor is responsible for creating the necessary draft to ensure proper combustion and venting. If the draft inducer motor is not working correctly, it can affect the pressure within the furnace and lead to an open pressure switch condition. Inspect the draft inducer motor for any signs of wear, damage, or improper operation. Ensure that the motor is running smoothly and is free of any obstructions. If the motor is malfunctioning, it may need to be repaired or replaced to restore proper draft and pressure.

7. Check for Furnace Leaks

Leaks in the furnace or ductwork can affect the pressure readings and cause the pressure switch to show an open condition. Inspect the furnace and ductwork for any signs of leaks or loose connections. Pay close attention to areas where the furnace connects to the ducts or where the venting system meets the furnace. Seal any leaks or gaps using appropriate materials, such as duct tape or sealant, to ensure that the pressure within the furnace is maintained correctly. Addressing leaks helps to restore proper pressure and eliminate open switch conditions.

8. Verify Proper Furnace Configuration

Ensure that the furnace is configured correctly according to the manufacturer’s specifications. An incorrect configuration can affect the pressure and cause the pressure switch to remain open. Review the furnace’s installation manual or specifications to verify that all components, including the pressure switch, inducer fan, and venting system, are set up correctly. Make any necessary adjustments to ensure that the furnace operates as intended and maintains the proper pressure for the pressure switch to function correctly.

9. Examine the Furnace Control Board

The furnace control board manages the operation of various components, including the pressure switch and inducer fan. If the control board is malfunctioning, it can affect the pressure switch readings and cause an open condition. Inspect the control board for any signs of damage, burnt components, or loose connections. If you suspect a problem with the control board, consult a professional HVAC technician to diagnose and repair or replace the board as needed. Proper control board operation is essential for maintaining correct pressure and preventing open switch conditions.

10. Consult a Professional HVAC Technician

If you have tried all the above methods and the pressure switch remains open with the inducer on, it may be time to consult a professional HVAC technician. A qualified technician can perform a comprehensive diagnosis of the furnace and its components to identify any underlying issues that may be causing the problem. They have the expertise and tools to address complex issues, such as faulty pressure switches, control board problems, or ventilation issues, ensuring that your furnace operates safely and efficiently.

Maintenance and Upkeep

Regular maintenance of your furnace is crucial for ensuring efficient operation and longevity. To keep your system running smoothly, develop a routine maintenance schedule that includes the following key tasks:

- Inspect and Replace Air Filters: Check the air filters monthly and replace them every 1-3 months, depending on usage. Clean filters improve airflow and efficiency while reducing strain on the furnace.

- Clean the Furnace Components: Dust and debris can accumulate in various parts of your furnace. Use a vacuum or a soft brush to clean the blower assembly, burners, and other accessible components to enhance performance.

- Check the Thermostat: Ensure your thermostat is functioning properly and calibrated accurately. Replace batteries if it’s a battery-operated model and consider upgrading to a programmable thermostat for improved energy efficiency.

- Inspect Safety Features: Regularly check the safety features of your furnace, including the carbon monoxide detector and high limit switch. Test the alarms on your detectors to ensure they are in working order.

- Schedule Annual Professional Tune-Ups: Consider scheduling a professional inspection and tune-up at least once a year. A qualified HVAC technician can perform a thorough check, cleaning, and necessary adjustments to keep your furnace operating safely and efficiently.

By performing these maintenance tasks regularly, you can help prevent unnecessary breakdowns, enhance the efficiency of your furnace, and extend its operational lifespan.

Conclusion

Maintaining your furnace is essential for ensuring its optimal performance, efficiency, and safety. By regularly testing key components, addressing potential issues like pressure switch problems, inspecting the furnace configuration, and conducting routine maintenance tasks, homeowners can significantly reduce the likelihood of costly repairs and extend the lifespan of their heating system. Thanks for reading, and we hope this has given you some inspiration on how to fix pressure switch open with inducer on!