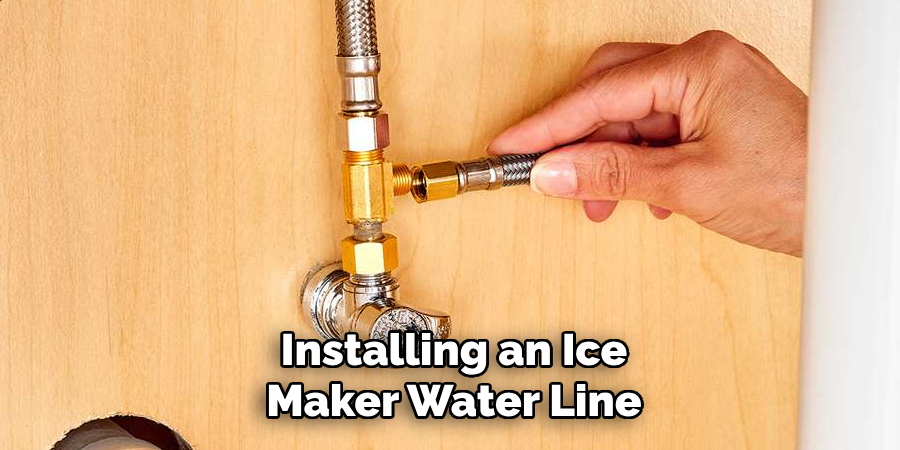

An ice maker is a convenient addition to any kitchen, providing a steady supply of ice for drinks, parties, and daily use. However, to ensure your ice maker operates efficiently, it’s essential to connect it to a reliable water source. Installing and properly maintaining an ice maker water line not only guarantees a consistent flow of water but also prevents leaks and potential water damage. This guide will walk you through how to ice maker water line safely and effectively.

What is an Ice Maker Water Line?

An ice maker water line is a dedicated tube or pipe that connects your ice maker to your home’s water supply. It serves as the essential conduit for delivering water to the ice maker, enabling it to produce ice automatically without the need for manual refilling.

Typically made of plastic or braided stainless steel, ice maker water lines are durable and designed to withstand consistent water flow. They are a critical component of the ice-making process, ensuring a steady and reliable supply of water for creating ice cubes. Proper installation and maintenance of the water line are crucial to avoid leaks, clogs, or other issues that could disrupt the efficiency of your ice maker.

Importance of a Properly Installed Water Line

A properly installed water line is essential for the optimal performance of your ice maker. It ensures a consistent and unhindered water supply, which is crucial for producing ice efficiently. Improper installation can lead to issues such as leaks, reduced water pressure, or even water contamination, impacting both the functionality and safety of your ice maker.

Additionally, a securely connected water line minimizes the risk of water damage to your kitchen or surrounding areas. Regular inspections and professional installation can help maintain the system’s reliability and extend the lifespan of your ice maker.

10 Methods How to Ice Maker Water Line

1. Identify the Nearest Cold Water Source

The first step in installing an ice maker water line is locating the nearest accessible cold water pipe. This source is typically found under the kitchen sink or in the basement directly below the refrigerator. Choosing the nearest water line minimizes the amount of tubing needed and simplifies the installation.

It’s crucial to confirm that the pipe is indeed for cold water, as connecting to a hot water line can damage the refrigerator and compromise ice quality. Once the pipe is located, shut off the water supply to prepare for the tap installation.

2. Use a Saddle Valve for Easy Tapping

One common and user-friendly method of accessing the water supply is using a saddle valve. A saddle valve clamps directly onto the chosen cold water pipe and pierces it with a needle-like tap when tightened. It’s a popular option because it doesn’t require pipe cutting or soldering, making it ideal for DIY installations.

However, ensure the valve is compatible with the pipe material (usually copper) and check your local plumbing codes, as saddle valves are not permitted everywhere due to long-term durability concerns.

3. Install a T-Fitting for a More Permanent Connection

For a more robust and long-lasting installation, consider using a T-fitting or compression tee. This involves cutting the cold water pipe and inserting a fitting that branches off to provide water to the ice maker. This method requires more plumbing knowledge but results in a safer and more code-compliant installation. You’ll need a pipe cutter, compression fittings, and possibly soldering tools depending on the pipe material. Once installed, this T-fitting provides a secure connection point for your water line.

4. Select the Appropriate Tubing Material

Choosing the right type of tubing is vital to ensure leak-free operation. Common materials include copper, braided stainless steel, and plastic (typically polyethylene). Copper tubing is durable and long-lasting but less flexible and harder to route through tight spaces.

Braided stainless steel offers strength and flexibility, making it easier to install in finished spaces. Plastic tubing is cost-effective and simple to cut but may not be as durable over time. Match your tubing to the type of installation you are doing and the existing plumbing.

5. Route the Tubing Safely to the Refrigerator

Once the tubing is connected to the water source, it must be routed carefully to the back of the refrigerator. Avoid sharp bends or kinks in the line, as they can restrict water flow or lead to leaks. If drilling through cabinets or floors is necessary, use a drill with the appropriate bit size and insert a plastic grommet or rubber bushing to prevent the tubing from rubbing against rough wood or metal edges. Leave some slack in the tubing behind the fridge to allow for movement during cleaning or maintenance.

6. Install a Shut-Off Valve for Safety

While saddle valves often function as shut-off points, installing a separate dedicated shut-off valve can provide added convenience and peace of mind. A quarter-turn ball valve is a reliable option that allows quick shut-off in case of leaks or maintenance. Mount the shut-off valve in an easily accessible location near the water source or behind the refrigerator. This addition enhances safety and complies with most building codes, especially for new constructions or major remodels.

7. Flush the Line Before Connecting

Before connecting the water line to the refrigerator, it’s important to flush the line to remove any debris or air trapped inside. To do this, open the shut-off valve and let water flow through the tubing into a bucket for several seconds. This step helps prevent small particles from clogging the refrigerator’s internal water filter or ice maker mechanism. After flushing, turn off the valve and dry the tubing ends before making the final connection.

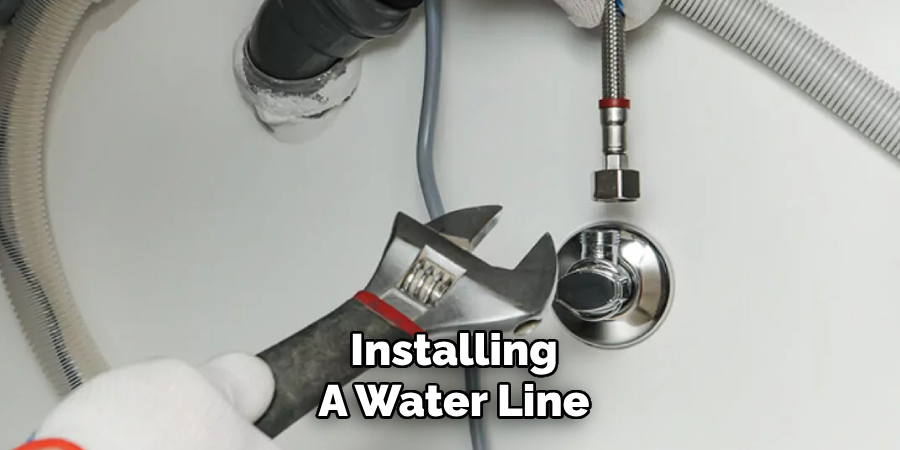

8. Connect the Tubing to the Refrigerator Inlet

Once flushed, connect the end of the tubing to the refrigerator’s water inlet valve, usually located on the lower back side. Most inlets accept a compression fitting or a threaded connector. Make sure the connection is secure but not overly tightened, as this can damage the fitting or cause leaks. If your tubing kit includes a plastic insert, ensure it is inserted into the tubing before tightening the compression nut, as it helps maintain a leak-proof seal.

9. Turn on the Water and Check for Leaks

With everything connected, slowly open the shut-off valve and inspect all connections for any signs of leakage. Watch carefully at both the water source and refrigerator ends. If you detect a leak, turn off the valve and retighten the connections or reapply thread seal tape if necessary. It’s a good idea to monitor the area for a few hours after the initial installation and check periodically over the next couple of days to ensure the system remains watertight.

10. Test the Ice Maker and Purge the First Batch of Ice

Finally, plug in the refrigerator and allow the ice maker to cycle. It may take a few hours for the first batch of ice to be produced. Discard the initial round of ice, as it might contain debris or tastes from the new tubing.

Some refrigerators include a test button for the ice maker to speed up the process. Once the ice production begins normally, confirm that the cubes are the correct size and that no unusual noises are coming from the water line.

Things to Consider When Setting Up Your Refrigerator

Proper Leveling

Ensure the refrigerator is placed on a level surface. An uneven placement can cause doors to close improperly, impacting cooling efficiency and leading to potential leaks or malfunctions.

Clearance Space

Leave adequate space around the refrigerator for ventilation. Without proper airflow, the compressor may overheat and reduce the appliance’s lifespan.

Water Line Installation

When connecting the water line for the ice maker or water dispenser, double-check for leaks and ensure the tubing is secure to prevent water damage.

Temperature Settings

Set the refrigerator and freezer compartments to the recommended temperatures—typically 37°F (3°C) for the fridge and 0°F (-18°C) for the freezer—for optimal performance.

Initial Cleaning

Before using the refrigerator, clean the interior with mild soap and warm water to remove any manufacturing residue or odors.

By addressing these considerations during setup, you can ensure your refrigerator operates efficiently and reliably.

Conclusion

Installing a water line to an ice maker can be a rewarding DIY task that significantly enhances the functionality of your refrigerator. From choosing the correct water source and fittings to selecting suitable tubing and ensuring a leak-free connection, each step requires attention to detail and care.

Whether you opt for a quick-install saddle valve or a more permanent compression T-fitting, the key to success lies in proper planning and safe execution. Thanks for reading, and we hope this has given you some inspiration on how to ice maker water line!