In the world of plumbing, selecting the appropriate materials is crucial for ensuring durability and efficiency. Among the options available, PEX (cross-linked polyethylene) has gained popularity due to its flexibility, resistance to corrosion, and ease of installation.

However, not all PEX materials are created equal, leading to distinctions between PEX-A and PEX-B. Understanding these differences is essential for plumbers and homeowners alike to make informed decisions about their plumbing systems.

This guide on how to identify pex a vs pex will help you identify the key characteristics of PEX-A and PEX-B, equipping you with the knowledge to choose the right type for your specific needs.

Why is It Important to Differentiate Between PEX-A and PEX-B?

Differentiating between PEX-A and PEX-B is crucial for several reasons. Firstly, the manufacturing process of PEX-A results in a more flexible material, which can expand and contract without sustaining damage during temperature fluctuations. This flexibility makes PEX-A ideal for residential plumbing systems where movement may occur.

Secondly, PEX-A has superior resistance to cracking and freezing, making it suitable for harsher climates. In contrast, PEX-B, while slightly more rigid, offers affordability and is preferred for various installations where excessive flexibility is not a primary concern. Understanding these distinctions allows homeowners and plumbers to select the most appropriate PEX type, ensuring the longevity and reliability of the plumbing system while also potentially saving on repair costs in the long run.

Needed Materials

- PEX-A Tubing

- PEX-B Tubing

- Heat Source (Hot Air Gun or Propane Torch)

- Scissors or Utility Knife

8 Simple Step-by-step Guidelines on How to Identify Pex a Vs Pex

Step 1: Observe the Color of the PEX Tubing

One of the easiest ways to differentiate between PEX-A and PEX-B is to observe the color of the tubing. Typically, PEX-A is available in a red and blue color scheme, indicating its suitability for hot and cold water supply lines, respectively. On the other hand, PEX-B is often found in a more muted shade, commonly white or gray, though it can also be red or blue.

While color alone is not a definitive identification method, it serves as a helpful visual cue in determining the type of PEX you are working with. Always check for additional markings on the tubing for more precise identification.

Step 2: Check for Markings on the Tubing

PEX-A tubing typically has a series of raised and embossed markings along its length, indicating its ASTM (American Society for Testing and Materials) standard. The standard for PEX-A is ASTM F876/877 or ASTM F1960, while PEX-B follows the standards of ASTM F2023 or ASTM F2389. These markings are usually found every few inches along the tubing’s length and can be easily felt by running your fingers over the surface.

In contrast, PEX-B tubing may also have markings but in a more subtle manner, such as printed ink labels rather than raised embossments.

Step 3: Bend the Tubing

One of the most significant differences between PEX-A and PEX-B is their respective flexibility. To identify if you have PEX-A, hold a few inches of tubing in both hands and bend it into an “S” shape. If the tubing retains its form when released, it is likely PEX-A as it has superior elasticity due to its manufacturing process.

If the tubing does not retain its shape and remains curved, it is likely PEX-B as it is slightly less flexible but still durable.

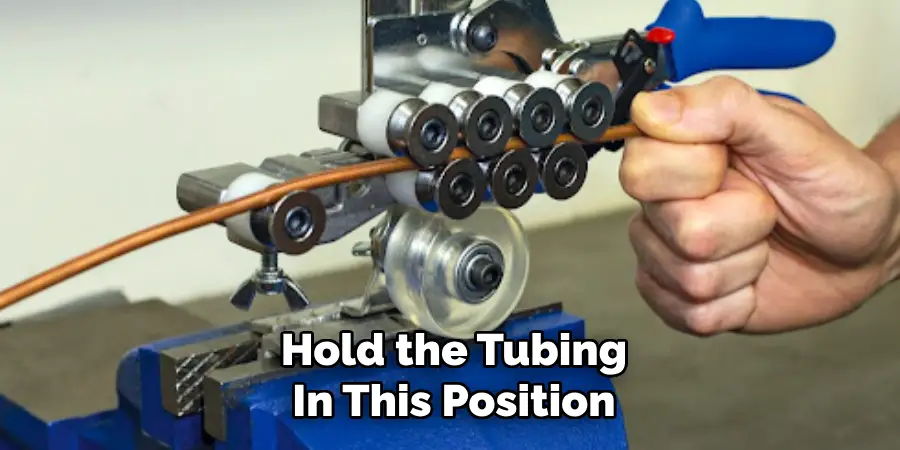

Step 4: Perform a Kink Resistance Test

To further differentiate between PEX-A and PEX-B, you can conduct a kink resistance test. Begin by taking a section of the tubing and bending it sharply to form a tight angle, creating a kink. Hold the tubing in this position for several seconds before releasing it. If the tubing springs back to its original shape without any noticeable damage or deformation, it indicates that you have PEX-A, as its manufacturing process provides enhanced kink resistance.

In contrast, if the tubing shows a permanent bend or crimp after the test, it is likely PEX-B, which exhibits less resilience to kinking. This test is particularly useful for assessing the long-term durability of the tubing in installations that may experience tight bends or require complex routing.

Step 5: Use a Heat Source

Another way to differentiate between PEX-A and PEX-B is to use a heat source. Using either a hot air gun or a propane torch, apply heat to a small section of the tubing for several seconds. If the tubing expands with minimal resistance, it indicates that you have PEX-A as it exhibits excellent shape memory from its manufacturing process.

In contrast, if the tubing resists expansion or becomes distorted when heated, then it is likely PEX-B, which has slightly less flexibility and elasticity due to its manufacturing method.

Step 6: Cut the Tubing

While this step may seem counterintuitive, cutting the tubing can also provide insight into its type. When using a scissor or a utility knife to cut PEX-A tubing, you will notice that the material is relatively easy to cut and leaves behind smooth edges with no jagged or frayed ends. The reason for this is due to the thermal memory of PEX-A, which allows it to retain its shape and form even after being cut.

In contrast, when cutting PEX-B tubing, you may experience some resistance as it is slightly less flexible. The resulting cut may also have rougher edges compared to PEX-A.

Step 7: Perform a Chlorine Resistance Test

PEX-A has superior chlorine resistance compared to PEX-B due to its unique manufacturing process. To test this, you can take a small section of the tubing and soak it in a solution of water and chlorine for an extended period. If the color or texture of the tubing remains unchanged after soaking, it indicates that you have PEX-A as it does not react to chlorine exposure.

In contrast, if the tubing shows signs of discoloration or degradation after soaking, it is likely PEX-B, which has slightly less resistance to chlorine and other chemicals. This test is particularly useful for installations where water quality or chemical exposure may be a concern.

Step 8: Consult with a Professional

If you are still unsure about the type of PEX you have, it is best to consult with a professional plumber or manufacturer. They will have the expertise and experience to accurately identify the type of PEX and provide further guidance on its appropriate use and installation requirements.

Following these eight simple steps on how to identify pex a vs pex can help you identify PEX-A and PEX-B quickly and accurately. Remember to always double-check for additional markings or consult with a professional with any questions, as using the wrong type of PEX in your plumbing system can lead to costly repairs and potentially hazardous situations.

So, it is essential to use the correct type for your specific needs. By understanding the differences between PEX-A and PEX-B, you can ensure a successful and efficient installation that will last for years to come.

Frequently Asked Questions

Q: Can PEX-A and PEX-B Be Used Interchangeably?

A: No, PEX-A and PEX-B have different properties and installation requirements, making them unsuitable for interchangeability. It is vital to identify the type of PEX you have before starting any plumbing project to ensure its proper use and compatibility with your system.

Q: Can I Use a Heat Source on Both PEX-A and PEX-B Tubing?

A: Yes, both types of tubing can withstand heat from hot air guns or propane torches. However, it is essential to exercise caution when using a heat source near any flammable materials or in confined spaces. Always follow safety guidelines and manufacturer’s instructions.

Q: What Are Common Uses for PEX-A and PEX-B Tubing?

A: PEX-A is often used in residential and commercial plumbing systems, radiant floor heating, and snowmelt systems due to its flexibility, kink resistance, and thermal memory. PEX-B is commonly used in potable water applications, such as underground water service lines or outdoor irrigation systems.

Q: Is One Type of PEX Better Than the Other?

A: It depends on your specific needs and installation requirements. Both PEX-A and PEX-B have their unique properties that make them suitable for different applications. Consult with a professional to determine which type of PEX is best for your project.

Conclusion

In summary, understanding the differences between PEX-A and PEX-B is crucial for making informed decisions regarding plumbing installations. Each type has its distinct characteristics, advantages, and ideal applications, making them suitable for specific circumstances. By following the outlined steps on how to identify pex a vs pex to identify the type of PEX you are working with, you can ensure proper usage that meets safety standards and enhances long-term performance.

Consulting with professionals when needed further reinforces the importance of making the right choice, ultimately leading to a reliable and efficient plumbing system. With this knowledge in hand, you can approach your project with confidence, knowing that you are equipped to select the most appropriate material for your needs.