Polybutylene pipes were widely used in residential plumbing from the 1970s to the 1990s, primarily due to their low cost and ease of installation. However, as time went on, it became evident that these pipes faced significant durability issues, leading to leaks and failures. Homeowners must identify polybutylene pipes in their plumbing systems, as the material’s brittleness can pose substantial risks, including water damage and costly repairs.

This article aims to provide essential methods and practical tips on how to identify polybutylene pipes within a home. Understanding the characteristics of these pipes and where they are commonly located can help homeowners take proactive measures to avoid plumbing problems and consider options for replacement or repair if necessary.

Characteristics of Polybutylene Pipes

Material and Appearance

Polybutylene pipes are typically recognized by their distinctive grey or blue color, which gives them a unique look compared to other plumbing materials. The texture of these pipes is smooth and resembles that of plastic, making them relatively lightweight and easy to handle during installation. Identifying markings are often present along the length of the pipe, displaying “PB” followed by a specific code that indicates the type of material and the manufacturer.

These markings are generally printed on the pipe’s surface, helping to confirm their identity. Compared to other common materials such as copper, PVC, and PEX, polybutylene pipes stand out due to their lack of metallic sheen (unlike copper) and flexibility (unlike rigid PVC). This flexibility allows for ease of installation in tight spaces, but it also contributes to long-term durability concerns.

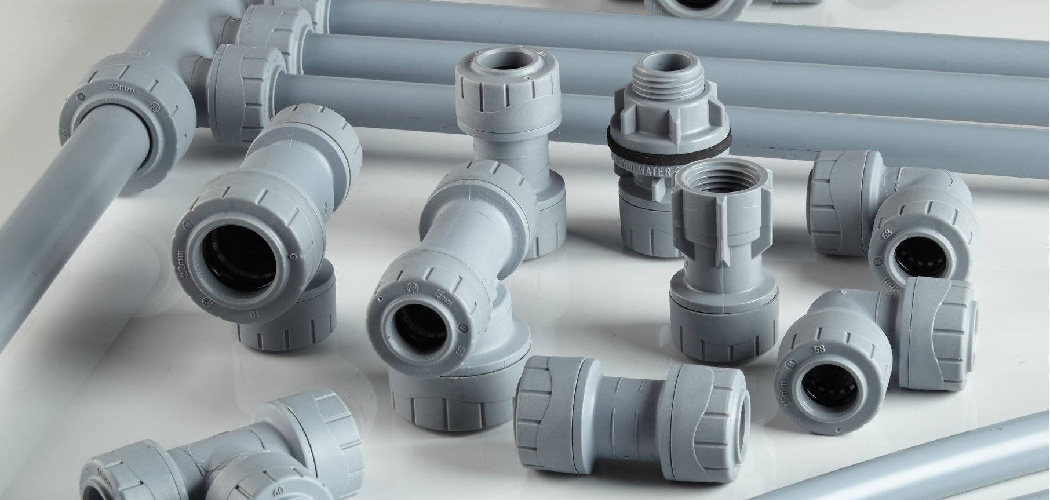

Fittings and Connections

Polybutylene pipes use unique fittings and connections, which differ from those found in other plumbing systems. Common fittings include crimp rings and insert fittings designed to create a secure connection between pipe segments. Unlike traditional threaded fittings used with metal pipes, these connections involve sliding the fitting over the pipe and securing it with a metal crimp ring.

During a visual inspection, homeowners should look for characteristics that indicate a polybutylene system, such as metal crimp rings and the specific designs of the connectors. Identifying these features is crucial for assessing the plumbing system’s condition and determining necessary actions for maintenance or replacement.

How to Identify Polybutylene Pipes: Locating Polybutylene Pipes in Your Home

Step 1: Inspecting Exposed Pipes

To effectively locate polybutylene pipes within your home, start by inspecting exposed areas where they are commonly found. These areas include basements, crawl spaces, and utility rooms, which often house plumbing systems. When conducting your inspection, look for the distinctive grey or blue color characteristics of polybutylene pipes.

Additionally, check for identifying markings along the pipe’s surface, such as the “PB” designation followed by a specific code indicating the pipe’s type and manufacturer. Inspect any visible sections of plumbing thoroughly, as these features are crucial for confirming the material and identifying potential risks associated with polybutylene pipes.

Step 2: Checking Pipe Documentation

Another effective method to locate polybutylene pipes is by reviewing home plumbing records and blueprints. If available, these documents can provide valuable insights into the types of materials used during construction or renovation. Look for home inspection reports or renovation documentation, including details about the installed plumbing system.

Without written records, consider contacting previous homeowners, plumbers, or contractors who may have insights into the plumbing materials used. Their knowledge can be instrumental in determining whether polybutylene pipes are part of your home’s plumbing system.

Step 3: Using a Pipe Identification Tool

In case visual inspections and documentation reviews are inconclusive, utilizing a pipe identification tool can be a helpful next step. Various tools and methods are available for accurately identifying pipe types, including pipe inspection cameras that can visually assess your plumbing system. Identification kits are also available on the market, which can help confirm the material of your pipes.

Hiring a professional plumber can be the most efficient solution if you find it challenging to identify the piping material on your own. Experts have access to advanced tools and techniques that can accurately assess the condition of your plumbing, ensuring that all risks related to polybutylene pipes are properly identified and addressed.

Recognizing Common Issues with Polybutylene Pipes

Pipe Degradation

Polybutylene pipes, while once a popular choice for plumbing, are prone to degradation over time, leading to significant issues within a home’s plumbing system. Common signs of degradation include discoloration, which may present as a dulling or fading of the pipe’s original grey or blue color, and physical changes such as cracking or flaking. These symptoms are often exacerbated by the material’s susceptibility to chlorine, frequently found in municipal water supplies, as well as extreme temperature fluctuations.

Such environmental factors can undermine the structural integrity of the pipes, making leaks more likely. Over time, polybutylene pipes may develop leaks or even burst, particularly at fittings or joints where stresses are compounded. Homeowners need to remain vigilant for these signs, as waiting too long to address degradation can lead to substantial water damage and costly repairs.

Preventive Measures and Repairs

To effectively manage risks associated with polybutylene pipes, homeowners should adopt proactive preventive measures. Regularly monitoring for leaks, especially at joints and connections, can help catch issues before they escalate. Additionally, it’s wise to insulate pipes to safeguard against extreme temperature changes, as this can mitigate the risk of cracking. If leaks occur or degradation is identified, several repair options are available.

Patching with epoxy or pipe sealant may be sufficient for minor leaks. However, for more extensive damage or for homeowners looking to eliminate future risks, upgrading to more durable pipe materials, such as PEX or copper, is advisable. These materials present greater durability and longevity, ensuring a more reliable plumbing system while removing the concerns associated with polybutylene pipes.

Replacement and Upgrading

When to Replace

Homeowners must consider replacing polybutylene pipes when extensive damage is evident or when frequent leaks occur, as these can lead to significant water damage and costly repairs. Visible signs of deterioration, such as cracks or discoloration, should prompt immediate evaluation. If any of these issues persist, seeking a replacement is advisable to avoid potential plumbing disasters.

Choosing New Pipes

When selecting replacement pipes, homeowners should opt for materials known for their reliability and longevity, such as PEX (cross-linked polyethylene) or copper. PEX pipes are flexible, resistant to scale and chlorine, and less likely to corrode, while copper pipes offer unmatched durability and longevity.

Hiring a Professional

To ensure a seamless installation, it’s recommended to hire a licensed plumber who is familiar with local plumbing codes and standards. A professional can accurately assess your needs, install the new piping system properly, and ensure long-term reliability.

Frequently Asked Questions About Polybutylene Pipes

Q1: What Are Polybutylene Pipes?

A1: Polybutylene pipes are plastic piping commonly used in residential plumbing systems from the 1970s to the 1990s. They are usually grey or blue in color and are known for their flexible properties.

Q2: Why Are Polybutylene Pipes Problematic?

A2: Over time, polybutylene pipes can degrade due to exposure to chlorine and temperature changes, leading to leaks and bursts. This can cause significant water damage and costly repairs for homeowners.

Q3: How Can I Tell if I Have Polybutylene Pipes in My Home?

A3: Polybutylene pipes can be identified by their distinctive grey or blue colour and by looking for the “PB” designation along their surface. Additionally, checking plumbing records and using identification tools can help confirm the material.

Q4: What Should I Do if I Find Polybutylene Pipes?

A4: If you identify polybutylene pipes, it’s advisable to monitor for signs of degradation and consider replacing them with more durable materials, such as PEX or copper. Consult a licensed plumber for an assessment and potential upgrades.

Q5: Can I Repair Polybutylene Pipes Instead of Replacing Them?

A5: Minor leaks can sometimes be repaired using epoxy or pipe sealant. However, replacement with a more reliable material is recommended for extensive damage or ongoing issues to prevent future risks.

Q6: Is It Necessary to Hire a Professional for Replacement or Upgrading?

A6: While some homeowners may choose to replace or upgrade their plumbing system on their own, hiring a licensed plumber is recommended for an accurate assessment and proper installation. They will also ensure compliance with local codes and standards. Overall, seeking professional assistance can save time, effort, and potential future issues related to the plumbing system. So, it is always advisable to hire a professional to replace or upgrade your home’s polybutylene pipes.

Conclusion

In summary, polybutylene pipes are a type of plastic piping that can present numerous risks due to their tendency to degrade over time, often resulting in leaks and water damage. Homeowners can implement various methods to identify these pipes, such as inspecting the physical characteristics of visible plumbing, reviewing documentation related to the home’s plumbing system, and using identification tools.

It is crucial for homeowners, especially those living in homes built or renovated between the 1970s and mid-1990s, to inspect their plumbing systems regularly. Taking proactive measures to monitor signs of wear and tear can prevent serious plumbing issues. Should any concerns arise, it’s essential to consider timely replacement with more durable materials like PEX or copper. Remember, knowing how to identify polybutylene pipes and addressing any potential problems promptly can save homeowners from significant repair costs and ensure the reliability of their plumbing systems.