Are you tired of experiencing leaks in your plastic pipes? Installing a shut-off valve can help prevent future leaks and make it easier to fix any issues. Here’s a step-by-step guide on how to install a shut off valve on plastic pipe.

Installing a shut-off valve on a plastic pipe is a practical plumbing task that can improve water flow control and allow for easy maintenance or repairs. Whether addressing a leak, replacing fixtures, or upgrading your plumbing system, adding a shut-off valve is straightforward when using the right tools and techniques.

This guide will walk you through installing a shut-off valve on a plastic pipe, ensuring a reliable and secure connection. With some preparation and patience, you can complete this DIY project efficiently.

What Are the Benefits of Using a Shut-Off Valve on Plastic Pipe?

Before we dive into the installation process, it’s essential to understand why installing a shut-off valve on your plastic pipe is beneficial. Here are some advantages:

- Water Flow Control: A shut-off valve lets you turn off the water supply to a specific fixture or section of your plumbing system without affecting other areas.

- Prevents Leaks: By installing a shut-off valve, you can quickly stop the water flow if there is a leak in that section. This prevents any further damage and gives you time to fix the issue.

- Easy Maintenance and Repairs: With a shut-off valve, you can isolate the area needing maintenance or repairs without shutting off the entire home’s water supply.

- Cost-effective: Installing a shut-off valve is an affordable and efficient solution for controlling water flow in your plumbing system, potentially saving you money on future repairs.

Now that you understand the benefits of installing a shut-off valve let’s go into the installation steps.

What Will You Need?

- Shut-off valve

- Pipe cutter or hacksaw

- Deburring tool

- PVC primer and cement (if using a PVC shut-off valve)

- Adjustable wrenches

- Teflon tape (for threaded connections)

You can start the installation process once you have all the necessary tools and materials.

10 Easy Steps on How to Install a Shut Off Valve on Plastic Pipe

Step 1. Turn Off the Water Supply:

Before starting any plumbing work, it’s critical to locate and turn off the main water supply to avoid leaks or flooding during installation. The main shut-off valve is typically found near the water meter or where the main water line enters your home. Once you’ve located the valve, turn it clockwise to completely shut off the water supply. After you’ve turned off the water, go to the nearest faucet and open it to relieve any remaining pressure in the pipes. This step ensures a safe and dry working environment, minimizing risks of water damage while you work on installing the new shut-off valve.

Step 2. Measure and Mark the Pipe:

Using a measuring tape, determine where the shut-off valve will be installed on the plastic pipe. Ensure the location is easily accessible for future use. Once the ideal spot is identified, use a marker to make clear, accurate marks on the pipe where it will be cut. These measurements should align with the valve’s inlet and outlet to ensure a secure fit. Double-check your markings before proceeding to the cutting step.

Step 3. Cut the Pipe:

Using a pipe cutter or a fine-toothed saw, carefully cut along the markings you made on the plastic pipe. Ensure your cuts are straight and clean to avoid fitting issues with the shut-off valve. Once the pipe has been cut, use a deburring tool or sandpaper to smooth any rough edges or debris. This step is crucial for creating a proper seal and preventing leaks when installing the shut-off valve. Always wear safety gloves and goggles while cutting to protect yourself from sharp fragments.

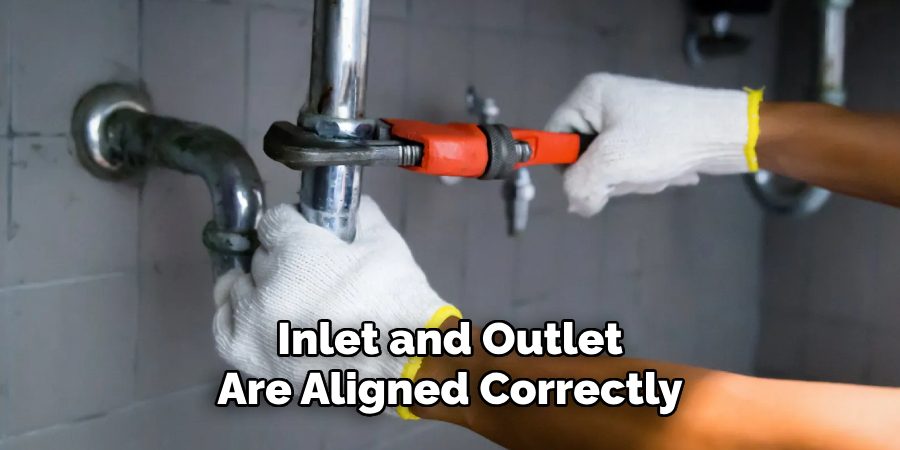

Step 4. Install the Shut-Off Valve:

Position the shut-off valve onto the prepared pipe ends, ensuring the inlet and outlet are aligned correctly. Gently slide the pipe ends into the valve fittings until firmly in place. Depending on the type of valve, you may need to secure it further by

tightening compression nuts, applying PVC cement, or using pipe clamps. Follow the manufacturer’s instructions for your specific valve model to ensure proper installation. Allow any adhesive or sealant to cure fully if required before proceeding to the next step.

Step 5. Test the Connection:

Once the shut-off valve is installed, testing the connection for leaks is essential. Slowly turn the water supply back on and observe the area around the valve. Check for any signs of dripping or moisture. If a leak is detected, tighten the fittings slightly or reapply the sealant as needed. Ensure the valve operates smoothly by opening and closing it a few times. Proper testing helps confirm the installation is secure and functioning correctly before regular use.

Step 6. Finalize and Clean Up:

After confirming that the shut-off valve is functioning correctly and there are no leaks, take a moment to clean up the work area. Wipe away any excess sealant or debris around the valve and pipes. Ensure that all tools and materials are accounted for and properly stored. Finally, inform anyone in the household about the location and use of the newly installed shut-off valve. This step ensures not only a tidy workspace but also that everyone knows how to operate the valve in case of an emergency.

Step 7. Monitor Over Time:

Even after installation and testing, it’s important to periodically check the shut-off valve to ensure it functions properly and remains leak-free. Over time, wear and tear or environmental factors, such as temperature changes and moisture, may

affect the valve and its surrounding connections. Make it a habit to inspect the valve at least once every few months. During these inspections, look for any signs of corrosion, rust, or leaks around the fittings. Turn the valve on and off to verify that it operates smoothly without becoming stuck or difficult to turn.

Step 8. Know When to Replace the Valve:

Over time, even the most durable shut-off valves may require replacement to ensure the safety and functionality of your plumbing system. If you notice persistent leaks, severe rust, cracks, or difficulty in turning the valve despite regular maintenance, it may be time to install a new one. Replacement is also recommended if the valve has been used for several years, as aging can weaken its components. Always choose a high-quality, compatible model suitable for your plumbing system when replacing the valve. If you are unsure about the replacement process, consulting a professional plumber is advised to ensure proper installation and functionality.

Step 9. Inspect and Test Regularly:

Routine inspections and testing of your shut-off valve are essential to maintaining its reliability. Schedule periodic checks to ensure no signs of wear, damage, or operational issues. During these inspections, confirm that the valve can be turned on and off without resistance and that no leaks are present. Regular testing can identify potential problems early, allowing you to address them before they lead to more significant plumbing issues.

Step 10. Understand Emergency Shut-Off Procedures:

Familiarizing yourself with the emergency shut-off procedures for your home or building’s water supply is crucial. Knowing how to locate and operate the main shut-off valve quickly can prevent extensive water damage during unexpected leaks or pipe bursts. Ensure all household members are aware of its location and understand how to turn it off in an emergency. Keep any necessary tools, such as a wrench, nearby for easy access.

By following these steps, you can successfully install a shut-off valve on your plastic pipe and ensure the security of your plumbing system.

5 Things You Should Avoid

- Using the Wrong Tools: Avoid using inappropriate tools that can damage the pipe or the valve. Ensure you have the correct tools, such as a pipe cutter and wrench, designed explicitly for plastic pipes.

- Applying Excessive Force: Over-tightening the valve or fittings can crack the plastic pipe. Always tighten components gently and follow the manufacturer’s recommendations.

- Skipping Proper Cleaning: Ensure the pipe ends are clean and debris-free before installation. Failure to do so can lead to leaks and improper sealing.

- Ignoring Proper Sealant: Avoid using an incorrect or excessive sealant. Use a sealant compatible with plastic pipes, like Teflon tape or thread sealant approved for plastic materials.

- Rushing the Installation: Do not rush the process. Ensure all components are aligned correctly and securely to avoid future issues such as leaks or misalignment. Take your time to inspect your work thoroughly.

Conclusion

How to install a shut off valve on plastic pipe requires careful preparation, proper tools, and attention to detail.

You can ensure a secure and leak-free installation by avoiding common mistakes, such as using excessive force, skipping cleaning, or rushing the process. Always follow the manufacturer’s guidelines and double-check your work to ensure all components are aligned and sealed.

Taking the time to do the job correctly will result in a durable and reliable connection, providing peace of mind and long-term performance.