CPVC (Chlorinated Polyvinyl Chloride) piping is a durable and versatile material widely used in residential, commercial, and industrial plumbing systems. Known for its high resistance to heat and corrosion, CPVC is an ideal choice for transporting hot and cold water. One of the key components in CPVC piping systems is the CPVC elbow, a fitting designed to enable changes in the direction of the pipe. These elbows ensure flexibility and adaptability, allowing water to flow seamlessly around corners or through tight spaces.

This article aims to provide a comprehensive step-by-step guide on how to install CPVC elbow fittings correctly. Proper installation is essential to achieve secure and leak-free connections, ensuring the longevity and efficiency of the plumbing system. Whether you are a beginner or an experienced DIY enthusiast, following these instructions will help ensure a successful and professional installation process.

What is a CPVC Elbow and Why Use It?

Definition of CPVC Elbow

A CPVC elbow is a specialized fitting designed to change the direction of CPVC pipes in a plumbing system. These elbows are available in different angles, commonly 90-degree and 45-degree variations, to accommodate various piping layouts. By enabling directional changes, CPVC elbows provide the flexibility needed to route pipes around obstacles or within confined spaces seamlessly.

Benefits of CPVC Elbows

CPVC elbows offer numerous advantages, making them an indispensable component of plumbing systems. One key benefit is their resistance to high temperatures and corrosion, which ensures durability and reliable performance even in demanding environments. Additionally, CPVC elbows are easy to install, allowing for quick and efficient assembly without requiring advanced tools. Their cost-effectiveness also makes them a popular choice for both residential and commercial plumbing projects, providing an ideal balance between affordability and performance.

Applications of CPVC Elbows

CPVC elbows are widely used in various applications due to their versatility and durability. They are an essential component in hot and cold water distribution systems, ensuring smooth and efficient water flow. Furthermore, CPVC elbows are frequently utilized in HVAC systems and industrial applications, where heat and chemical resistance are critical. Their adaptability and reliability make them a trusted choice for various plumbing needs.

Tools and Materials Needed for Installation

Essential Tools

- Pipe cutter or hacksaw: Used for cutting CPVC pipes to the desired length.

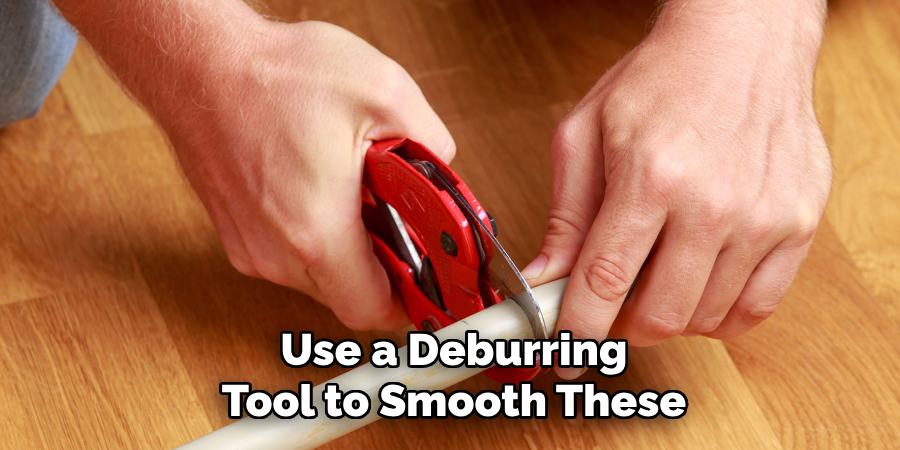

- Deburring tool: Ensures the edges of the cut pipe are smooth, preventing damage during fitting.

- PVC primer and cement: Necessary for securing and sealing the CPVC elbow to the pipe.

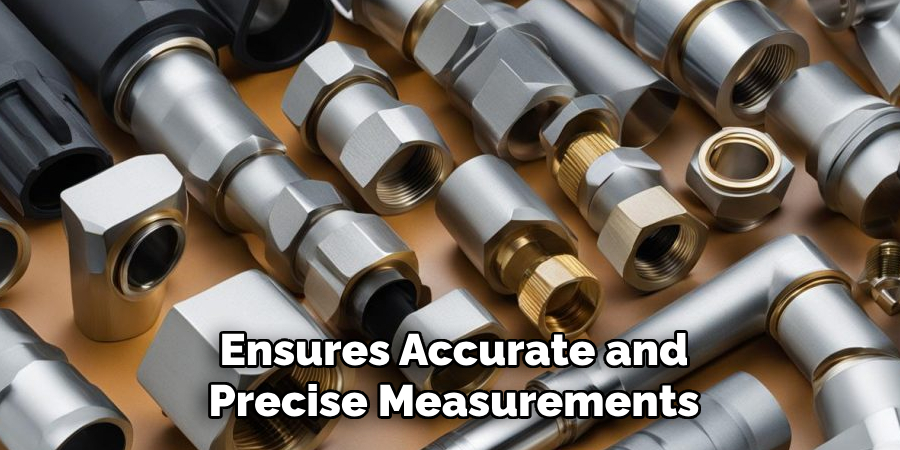

- Measuring tape: Ensures accurate and precise measurements for proper pipe alignment.

- Clamps: Holds the pipes securely in place during the installation process.

Materials

- CPVC elbow fitting: Choose 90-degree or 45-degree elbows as required for the plumbing system.

- CPVC pipe sections: Ensure you have the correct diameter and length of pipe for your project.

- PVC cleaner: Prepares and cleans the pipe surfaces to ensure a strong bond during installation.

Having the proper tools and materials ensures a straightforward, efficient installation process and maximizes the durability and reliability of the final plumbing system.

Preparing the Pipes and Elbow for Installation

Shutting Off the Water Supply

Before starting the installation, shutting off the water supply is essential. This step prevents leaks, ensures safety, and allows for a smooth installation process. Locate the main water valve and turn it off completely before proceeding with any pipework.

Measuring and Cutting the CPVC Pipe

Accurate measurements are crucial for a successful installation. Use a measuring tape to determine the exact length needed for the CPVC pipe. Mark the desired length clearly using a pencil or marker. Then, use a pipe cutter or hacksaw to cut the pipe along the marked line. A clean, straight cut is important to ensure proper alignment and sealing during the installation.

Deburring the Pipe Ends

After cutting the pipe, the edges may be rough or uneven. Use a deburring tool to smooth these edges. This step is necessary to avoid damaging the elbow fitting and to achieve a secure fit. Properly deburred pipes also reduce the risk of uneven glue distribution, improving the overall durability of the connection.

Cleaning the Pipe and Elbow

Both the pipe and the CPVC elbow fitting must be thoroughly cleaned before assembly. Apply PVC cleaner to the surfaces to remove dust, oils, and any other contaminants. This step ensures a strong and secure bond when the primer and cement are applied, enhancing the reliability of the joint.

How to Install CPVC Elbow: Step-by-Step Guide

Step 1: Applying PVC Primer

Begin by applying PVC primer to both the inside surface of the CPVC elbow fitting and the outside of the pipe end. The primer is essential for softening the surfaces and removing any remaining contaminants. This step ensures that the CPVC materials are properly prepared for a strong chemical bond. Cover the areas evenly, and allow the primer to dry for a few seconds before proceeding.

Step 2: Applying PVC Cement

Once the primer has dried, apply a generous and even coat of PVC cement to the primed surfaces—the inside of the elbow fitting, and the outside of the pipe ends. The cement should not pool or drip excessively but ensure good coverage for a secure bond. Work quickly, as the cement begins to set rapidly after application.

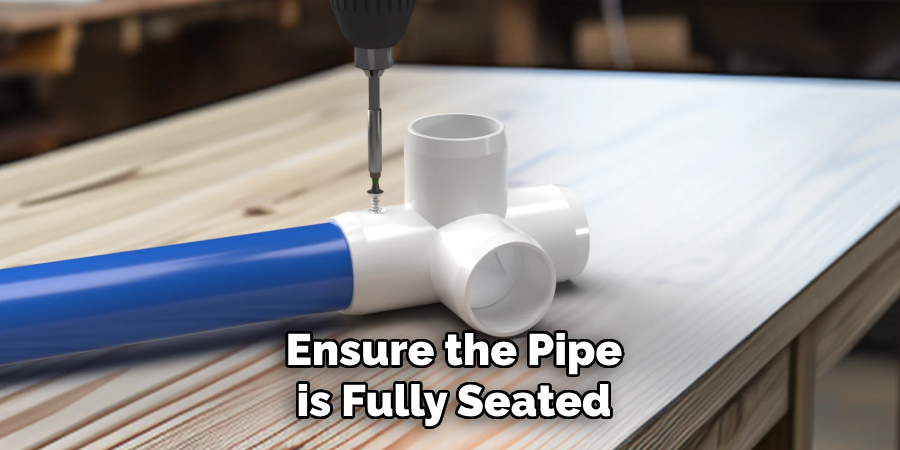

Step 3: Attaching the CPVC Elbow

Immediately after applying the cement, insert the pipe ends into the CPVC elbow fitting. Push firmly while twisting slightly to distribute the cement evenly and create a tight seal. Ensure the pipe is fully seated within the fitting, and hold the connection in place for at least 30 seconds to allow the cement to set and bond the materials securely.

Step 4: Checking for Proper Alignment

Once the joint is assembled, check that the pipes and elbow are aligned correctly at the desired angle (e.g., 90-degree or 45-degree). Proper alignment is crucial to ensuring the overall system functions as intended. Use pipe clamps if necessary to hold the pipes and joints in position while the cement fully cures, which may take several hours.

Allowing the Cement to Cure

Curing Time for PVC Cement

After assembling the joint, it is essential to allow sufficient time for the cement to cure properly. Most manufacturers recommend a curing period of at least 2 hours for light handling and a full 24 hours for the cement to achieve its maximum strength. Avoid applying pressure to the pipes or turning on the water supply during this time, as any disturbance could compromise the bond and lead to leaks or weak connections.

Importance of Full Cure

Ensuring the fully cured cement is critical for creating a durable and leak-resistant joint. During the curing process, the solvent bonds the CPVC materials, effectively fusing them into a single, solid structure. Rushing this step or skipping the recommended curing time may result in a system that is prone to failure, potentially requiring costly repairs or rework.

Checking for Leaks

Once the curing time has elapsed, carefully inspect the installation for any visible issues before using the system. Turn on the water supply gradually and monitor the connection for any signs of dripping or water seepage. If leaks are detected, turn off the water immediately and re-examine the joint to ensure proper assembly and sealing. A fully cured and leak-free bond is vital for the long-term functionality of the piping system.

Allowing the Cement to Cure

Curing Time for PVC Cement

After applying PVC cement, allowing the joint to cure for the recommended duration is essential before using the system. Typically, it takes about 2 hours for the cement to handle light loads and 24 hours for a complete cure under normal temperature and humidity conditions. During this time, avoid any external stress or movement that could disrupt the joint, as these factors may weaken the bond and compromise the waterproof integrity of the connection.

Importance of Full Cure

Adhering to the full curing time is critical for ensuring a strong and durable connection. Proper curing allows the cement to fully bond with the CPVC surfaces, effectively creating a solid, uniform joint that resists leaks and structural failure. Skipping this step or rushing the process increases the risk of defects, which could lead to costly repairs and potential water damage in the piping system.

Checking for Leaks

Once the curing period has elapsed, thoroughly inspect the joint before turning the water supply back on. Gradually introduce water into the system and closely monitor the connections for any signs of leaking or seepage. If a leak is detected, turn off the water immediately and inspect the assembly to identify and resolve the issue. Ensuring a leak-free joint is crucial for your piping system’s long-term reliability and efficiency.

Common Installation Issues and How to Fix Them

Misalignment of Pipe and Elbow

One common issue during CPVC pipe installation is the pipe and elbow joint misalignment. If the parts are not properly aligned before the cement sets, it can leak or hinder water flow through the system. To fix this, ensure that all pipes and fittings are dry-fitted prior to applying the cement. Mark alignment points on the pipe and fit with a pencil or marker to guide proper placement. If misalignment occurs during installation, you can attempt to re-align the parts immediately but work quickly before the cement sets fully.

Excessive PVC Cement

Applying too much PVC cement can lead to messy installations and create weak spots in your connection. Excess cement may squeeze out of the joint and even drip inside the pipe, compromising the system’s performance. To avoid this, use a uniform and moderate amount of cement. Apply the cement evenly around the pipe and fitting surfaces using an appropriately sized applicator, ensuring a smooth and thorough coat. Do not over-saturate the surfaces, as excess application is unnecessary for effective bonding.

Cement Dripping Inside the Pipe

If cement drips inside the pipe, it can lead to blockages that obstruct water flow. To prevent this, monitor the application process closely and avoid over-applying cement. If drips occur, use a clean cloth to wipe away excess cement before it sets. After assembling the pipes, inspect both ends to ensure no cement has seeped into the waterway.

Inadequate Curing Time

Rushing the curing period is another frequent mistake that can result in leaks or joint failure. Always follow the manufacturer’s recommended curing timeline to ensure a reliable bond. Avoid pressurizing the system until the necessary curing time has passed. If unsure, give the connection additional time to cure. Proper handling and patience during this stage will ensure a durable and leak-free installation.

Testing and Inspecting the Installed CPVC Elbow

Pressure Testing the Plumbing System

Running a pressure test after installation is crucial to confirm the integrity of the CPVC elbow joint. Begin by capping the ends of the plumbing system and using a pressure pump to apply the recommended test pressure as specified by the manufacturer. Monitor the system for a set duration to ensure no drops in pressure occur, indicating potential leaks.

Visual Inspection

A close visual inspection of the joint is essential to identify any signs of cracks, gaps, or improper bonding that could compromise the system. Examine the elbow connection from all angles to verify that the cement has been applied evenly and cured properly.

Performing a Leak Test

To further ensure the reliability of the joint, apply a leak detection solution such as soapy water around the elbow. Turn on the water supply or pressurize the system slightly and observe for any bubbles forming at the joint, which would indicate a leak.

Rechecking the System After 24 Hours

After the recommended curing period has passed, usually 24 hours or more, restore the water supply and inspect the system again. Check for any leaks or irregularities around the joint to confirm the installation is fully secure and ready for long-term use. Taking these steps ensures a properly functioning and leak-free plumbing system.

Conclusion

Installing a CPVC elbow involves several crucial steps to ensure a secure and leak-free connection. Beginning with preparation, cutting the pipe to the correct length, and priming, each step plays a vital role. Proper bonding with CPVC cement, followed by adequate curing time, solidifies the joint, making it durable for long-term use. Testing for leaks and rechecking the system after 24 hours are essential to verify the installation’s reliability. Correct alignment and curing are critical for success. Regular inspections should be performed to maintain system integrity. Knowing “how to install cpvc elbow” ensures a durable plumbing system.