Copper pipes are one of the most common materials used for plumbing, water supply, and heating systems. They are durable, long-lasting, and resistant to corrosion. However, copper pipes can also be a source of energy loss if not properly insulated.

Uninsulated or poorly insulated copper pipes can result in higher energy bills due to heat loss and may also lead to frozen pipes during the winter. Furthermore, uninsulated pipes can contribute to condensation, which can cause damage to your walls or ceilings. In this guide, we will discuss how to insulate copper pipes and save energy in the process. So, let’s get started!

Understanding the Need for Pipe Insulation

Before we dive into the process of insulating copper pipes, it is essential to understand why it is necessary in the first place. As mentioned earlier, uninsulated or poorly insulated pipes can lead to energy loss and damage to your home. Insulation helps prevent heat transfer from the pipes, keeping the water inside hotter for longer periods. It also prevents cold air from entering and surrounding the pipes, reducing the chances of frozen pipes.

Additionally, pipe insulation can also help reduce noise from running water and eliminate condensation, which can lead to mold growth and other structural issues. So, investing in pipe insulation not only helps save energy but also protects your home from potential damage.

Types of Pipe Insulation

There are various types of pipe insulation available in the market, and each one serves a specific purpose. The most common type is foam pipe insulation, which is made of polyethylene or neoprene foam. This type of insulation comes in pre-slit tubes that can easily be slipped onto the pipes.

Foam insulation is affordable, easy to install, and highly effective in preventing heat loss. Another type of pipe insulation is fiberglass, which comes as a wrap or tape and is typically used for long stretches of pipes. Fiberglass insulation has excellent thermal properties but can be a bit more challenging to install compared to foam insulation. Other types of pipe insulation include rubber, foam-in-place, and reflective foil insulation.

Tools and Materials You Will Need to Insulate Copper Pipe

- Foam or fiberglass pipe insulation

- Insulation tape or adhesive

- Scissors or utility knife

- Measuring tape

- Protective gloves and eyewear

- Caulking gun (for foam-in-place insulation)

- Insulation hangers (for foam-in-place insulation)

Step-by-step Guidelines on How to Insulate Copper Pipe

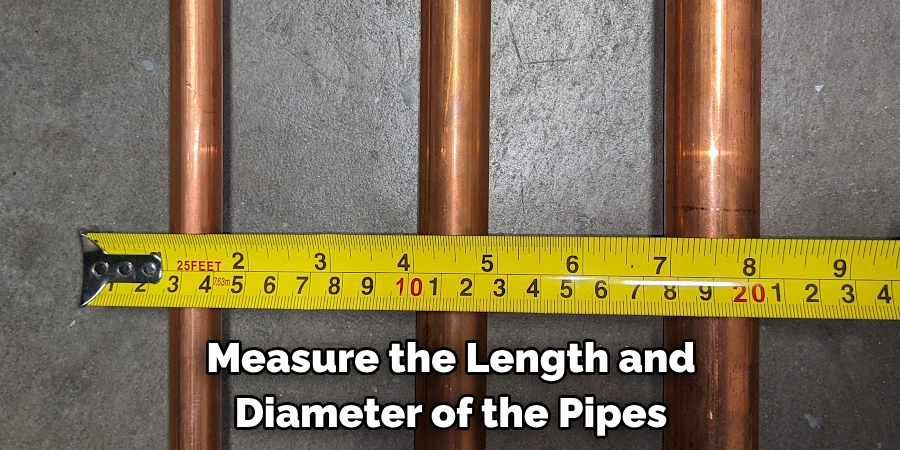

Step 1: Measure and Prepare the Pipes

Before you begin insulating, measure the length and diameter of the pipes to determine the amount of insulation needed. Next, clean any debris or dirt from the pipes using a damp cloth. If there are any sharp edges or protrusions on the pipes, cover them with insulation tape to prevent damage to the foam or fiberglass. Preparing the pipes beforehand ensures a smooth and effective insulation process.

Step 2: Cut and Install the Insulation

Using a measuring tape, mark the length of pipe insulation needed, and cut it using scissors or a utility knife. For foam insulation, make sure to cut it slightly longer than the measured length to leave room for compression when fitting onto curved pipes. For fiberglass insulation, make sure to wear gloves and eyewear when handling as the fibers can irritate the skin. Once cut, simply wrap or slip the insulation onto the pipes, making sure there are no gaps or overlaps.

Step 3: Seal Any Gaps with Insulation Tape

If there are any gaps between sections of insulation or around joints or bends in the pipe, use insulation tape to seal them. This will ensure maximum efficiency in preventing heat loss and protecting against condensation. Sealing also helps prevent the insulation from slipping or moving out of place. If using foam-in-place insulation, follow the instructions on the packaging to properly seal any gaps.

Step 4: Secure with Insulation Hangers (for Foam-in-place Insulation)

If you are using foam-in-place insulation, use insulation hangers to secure the foam in place while it sets. These hangers will keep the insulation from expanding and moving out of place during the drying process. If you are using another type of insulation, skip this step. This step is not necessary for foam or reflective foil insulation.

Step 5: Check and Test the Insulation

After completing the insulation process, check for any gaps or areas that may need additional sealing. Once satisfied, turn on your hot water faucet to ensure proper flow and test the effectiveness of the insulation. If you feel any heat loss from the pipes, consider adding more insulation or sealing any gaps. Checking and testing the insulation ensures that you have properly insulated your copper pipes and will result in maximum energy savings.

Following these simple steps will help you properly insulate your copper pipes and save money on energy costs in the long run. Remember to regularly check and maintain your pipe insulation to ensure its effectiveness. Properly insulated pipes not only save energy but also protect your home from potential damage, making it a worthwhile investment. So, don’t wait any longer; get started on insulating your copper pipes today! Happy insulating!

Additional Tips and Tricks to Insulate Copper Pipe

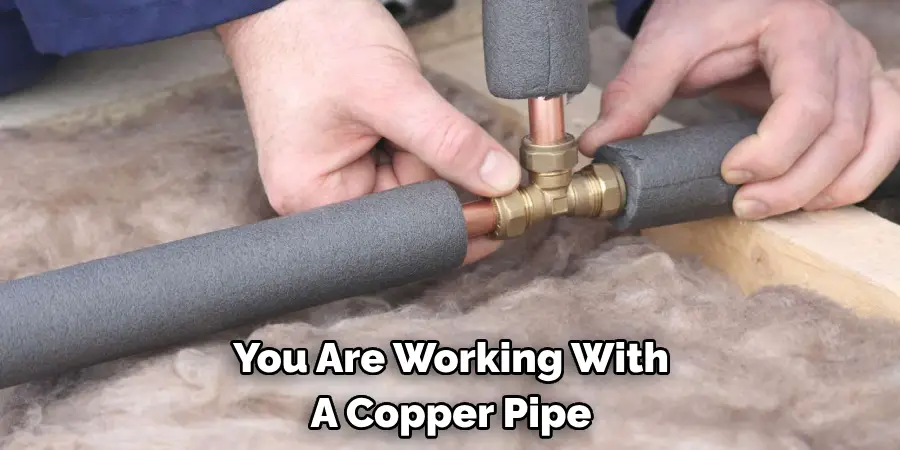

1. If you are working with a copper pipe that is already installed and cannot be easily removed, there are still methods for insulating it. One option is to use pre-slit foam insulation tubes that can slide over the pipe and snap into place. Another option is to wrap the pipe with layers of foam or fiberglass insulation and secure it with duct tape.

2. When insulating outdoor copper pipes, it is important to use weather-resistant materials. This can include foam or fiberglass insulation with a protective coating, such as plastic or rubber.

3. For an added layer of protection, you can also wrap the insulated pipe with a layer of reflective foil tape. This will help reflect heat and prevent cold air from penetrating the insulation.

4. In areas where there may be high levels of moisture, such as near a water heater or in a basement, it is recommended to use closed-cell foam insulation. This type of insulation is less likely to absorb moisture and can provide better protection against freezing temperatures.

5. When insulating pipes that are located in areas with limited space, consider using thinner materials such as self-sealing foam tape. This will allow you to easily wrap the pipe and ensure a secure fit without taking up too much space.

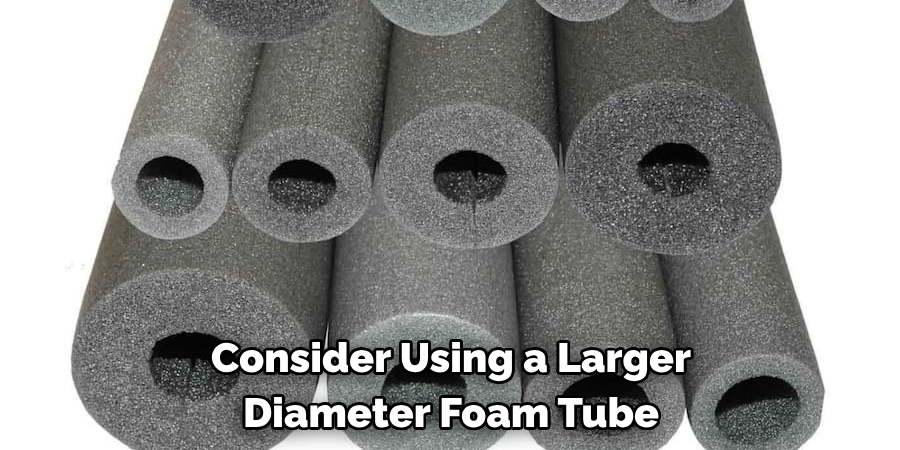

6. If you are insulating multiple pipes that are close together, consider using a larger diameter foam tube or insulation blanket to cover them all at once. This can save time and ensure that all of the pipes are properly insulated.

7. Don’t forget about any exposed fittings or joints in the copper pipe. These areas are more prone to freezing and should also be insulated with foam or fiberglass insulation.

8. If you are unable to insulate all of your copper pipes at once, prioritize those that are located in unheated areas or near exterior walls. These pipes are more susceptible to freezing and should be insulated first.

9. Regularly check on your insulated pipes to ensure that the insulation is still in good condition and has not worn away or become damaged. If you notice any issues, replace the insulation immediately to maintain proper protection.

Following these additional tips and tricks can help ensure that your copper pipes are properly insulated and protected against freezing temperatures. Remember to always use the proper materials and techniques for insulating your pipes to ensure optimal results. By taking the time to properly insulate your copper pipes, you can avoid costly repairs and potentially dangerous situations. So don’t skip this important step when it comes to maintaining your plumbing system. Stay warm and safe with well-insulated copper pipes!

Things You Should Consider to Insulate Copper Pipe

1. The first thing to consider when insulating copper pipes is the type of insulation material you will use. There are various types of insulation materials available such as foam, rubber, fiberglass, and more. Each type has its advantages and disadvantages, so it’s important to research and choose the best one for your specific needs.

2. Another factor to consider is the thickness of the insulation material. The thicker the insulation, the better it will be at keeping heat in or out, depending on its purpose. Thicker insulation also provides more protection against physical damage to the pipes.

3. It’s important to properly measure and cut the insulation material to fit your specific pipe size. If the insulation is too loose or too tight, it won’t effectively insulate the pipe and could lead to future issues.

4. When insulating copper pipes, make sure to seal any gaps or joints with tape or adhesive. This will prevent any air leaks and ensure the insulation is effective.

5. Consider the location of the pipes when choosing an insulation material. If the pipes are located in a high-humidity area, it’s important to choose an insulation material that is resistant to mold and mildew.

6. Take into account the cost of the insulation material when making your decision. Some materials may be more expensive upfront but may provide better long-term insulation and savings on energy bills.

7. It’s also important to consider any local building codes or regulations when insulating copper pipes. Some areas may have specific requirements for insulation materials and installation methods.

8. Regular maintenance of the insulation is crucial to ensure its effectiveness. Inspect the pipes and insulation periodically for any signs of damage or wear and replace or repair as needed.

9. If you are unsure about how to properly insulate copper pipes, it’s best to consult a professional plumber. They can guide you in selecting the right insulation materials and ensure proper installation for optimal insulation.

10. Lastly, consider the environmental impact of the insulation material you choose. Some materials may be more eco-friendly and sustainable than others, so it’s important to weigh this factor in your decision-making process.

Following these considerations can help ensure that your copper pipes are properly insulated and protected from heat loss or damage. Proper insulation can also lead to energy savings and a longer lifespan for your plumbing system. Don’t neglect the importance of insulating your copper pipes, as it can have long-term benefits for both your home and the environment. So, make sure to carefully consider all factors before making a decision. Happy insulating!

Maintenance Tips for Copper Pipe

1. Check for Leaks Regularly:

The first step in maintaining your copper pipes is to check for any leaks regularly. Leaks can occur due to various reasons such as corrosion or loose fittings. If left unchecked, leaks can lead to water damage and increase your water bill significantly. To check for leaks, visually inspect your pipes for any signs of moisture or puddles around them. You can also run your hand along the pipes to feel for any wet spots. If you notice any leaks, it is important to fix them immediately.

2. Insulate Your Pipes:

Insulating your copper pipes can help prevent freezing during colder months and reduce the risk of bursting. You can insulate your pipes with foam pipe insulation or even old towels or blankets. Be sure to cover all exposed areas of the pipe, including bends and joints. Insulating your pipes can also help reduce heat loss, which can save you money on your energy bill.

3. Keep Pipes Clean:

Regularly cleaning your copper pipes is essential to maintain their longevity. Over time, the buildup of minerals and debris can cause corrosion and blockages in the pipes. To clean your pipes, you can use a mixture of equal parts vinegar and water. Simply pour the mixture into the pipes and let it sit for a few hours before rinsing it out with hot water. This will help remove any buildup and keep your pipes flowing smoothly.

4. Monitor Water Pressure:

High water pressure can put strain on your copper pipes and increase their risk of developing leaks. It is important to monitor your water pressure regularly to ensure it is within the recommended range of 40-60 psi. If your water pressure is higher than this, you can install a pressure-reducing valve to regulate it. This will not only prevent damage to your pipes but also save you money on your water bill.

5. Schedule Professional Inspections:

In addition to regular maintenance tasks, it is important to schedule professional inspections for your copper pipes. A professional plumber can identify any potential issues and address them before they turn into costly repairs. They can also provide advice on the best ways to maintain your specific type of copper pipes. It is recommended to have a professional inspection every 1-2 years.

By following these maintenance tips, you can ensure the longevity and efficiency of your copper pipes. Remember to check for leaks regularly, insulate your pipes, keep them clean, monitor water pressure, and schedule professional inspections. With proper maintenance, your copper pipes can last for decades without causing any major issues. So make sure to incorporate these tips into your regular home maintenance routine to avoid any potential problems in the future. Happy piping!

Frequently Asked Questions

What is Insulation for Copper Pipe?

Insulation for copper pipe refers to a material that is used to cover or wrap around the copper pipe to prevent heat loss and maintain the temperature of the liquid flowing through it. It also serves as protection against condensation and corrosion. Insulation for copper pipe is commonly made of foam, rubber, or fiberglass and can be purchased in different sizes and thicknesses to fit various pipe diameters.

Can I Insulate Copper Pipes Myself?

Yes, you can insulate copper pipes yourself with the proper tools and materials. However, it is recommended to consult a professional plumber or contractor if you are not familiar with insulation techniques, as improper installation can lead to damage or inefficiency in your plumbing system.

What Benefits Does Insulating Copper Pipe Provide?

The main benefit of insulating copper pipes is energy efficiency. By reducing heat loss, insulated pipes can help you save on your energy bills by allowing hot water to stay warmer for longer periods without the need for constant reheating. Additionally, insulation helps prevent frozen pipes in colder environments and reduces the risk of condensation and corrosion. Insulation also helps to reduce noise from water flowing through the pipes.

What Thickness of Insulation Should I Use for My Copper Pipes?

The thickness of insulation required for your copper pipes depends on various factors such as the location and climate, temperature of the liquid flowing through the pipes, and the desired level of energy efficiency. In general, a thickness of ½ to 1 inch is recommended for most residential applications. However, for extreme temperatures or industrial settings, thicker insulation may be necessary.

What are the Different Types of Insulation for Copper Pipes?

There are several types of insulation materials available for copper pipes. The most common ones include foam (polyethylene or rubber), fiberglass, and mineral wool. Foam insulation is easy to install and has a high R-value (a measure of insulation’s ability to resist heat flow). Fiberglass is more durable and can withstand higher temperatures. Mineral wool has excellent thermal properties and is resistant to fire and moisture.

Conclusion

Now you know how to insulate copper pipe and the benefits it provides. Whether you choose to insulate your copper pipes yourself or hire a professional, proper insulation can help save energy, protect against freezing and damage, and reduce noise.

Be sure to consider the climate and temperature of your area when choosing the thickness of insulation for optimal efficiency. Remember to regularly check for any signs of wear or damage on your insulated pipes and replace them if necessary. With the right insulation, you can ensure that your plumbing system runs smoothly and efficiently for years to come. So, be sure to choose the appropriate type of insulation for your copper pipes and enjoy the benefits it provides!