Are you looking to repair or install new pipes in your home? Plumb pipe strapping is crucial in ensuring your pipes are secure and properly supported.

When it comes to securing pipes in place, understanding how to plumb pipe strap is essential for both functionality and durability. Pipe straps serve as a reliable method to fasten pipes to walls, ceilings, or other surfaces, ensuring stability and preventing unwanted movement.

Whether you’re working on a plumbing project, gas line installation, or securing electrical conduits, correctly using pipe straps can make a significant difference in the longevity and safety of your work.

This guide will walk you through the fundamentals of plumbing pipe straps, covering the tools, techniques, and precautions needed to achieve a professional result.

What Are the Benefits of Plumb Pipe Strap?

Plumb pipe straps are versatile and have many benefits to offer, such as:

- Strong Support: With the right size and installation technique, pipe straps can provide excellent support for pipes, preventing them from sagging or breaking under pressure.

- Easy to Install: Installing pipe straps requires no special tools or skills. This is why it’s a popular choice among DIYers and professional plumbers.

- Cost-effective: Pipe straps are affordable and readily available at most hardware stores. You can purchase them in different materials, sizes, and configurations to suit your needs.

- Space-saving Solution: Compared to other methods of securing pipes, such as clamps or brackets, pipe straps take up less space and can be installed closer to walls or ceilings, making them ideal for tight spaces.

These are just some benefits that make plumb pipe straps a go-to choice for securing pipes in various applications. Keep reading to learn more about how to use them effectively.

What Will You Need?

Before getting started, gather the following tools and materials:

- Pipe straps (metal or plastic)

- Screws (appropriate for the surface you will be attaching the strap to)

- Screwdriver

- Level

- Pencil

Once you have all the necessary items, it’s time to start your project.

9 Easy Steps on How to Plumb Pipe Strap

Step 1: Plan Your Placement

Before attaching any pipe straps, you must plan where you will place them. Review your plumbing setup and identify the pipes that need support. Consider factors like the weight of the pipes, the type of fluid they carry, and the distance between other supports.

Avoid placing straps too far apart for longer pipe runs to prevent sagging or undue stress on the pipes. Use a level to ensure the pipes remain straight; uneven placement could lead to functional issues or complications during future maintenance.

Mark the placement spots with a pencil for accuracy, ensuring the points are easily accessible and won’t interfere with other structures or systems. Planning at this stage will make the process smoother and provide a secure, professional result.

Step 2: Choose the Right Pipe Straps

Select pipe straps that are appropriate for the pipe material and size you are working with. Pipe straps come in various designs and materials, including metal and plastic, to accommodate different applications. For heavier pipes or those exposed to high temperatures, opt for durable metal straps, such as galvanized or stainless steel, for added strength and longevity.

If you are working with lightweight or PVC pipes, plastic straps may suffice. Ensure the strap size matches the diameter of the pipe snugly without causing compression or restriction. Having the right straps will ensure a secure fit and maintain the integrity of the plumbing system.

Step 3: Mark and Drill Mounting Holes

Once you’ve selected the appropriate pipe straps, position the pipe and mark the locations where the straps will be mounted. Use a measuring tape to ensure the marks are evenly spaced and aligned to support the pipe adequately.

With the marks in place, drill pilot holes into the mounting surface using a drill bit that matches the size of the screws you plan to use. Pilot holes will make it easier to secure the screws and prevent cracking or damage to the surface. Drill perpendicular to the surface for a stable and accurate fit.

Step 4: Secure the Pipe Straps

With the pilot holes drilled, align the pipe straps over the pipe and match them to the marked holes. Insert screws through the strap holes and into the pilot holes, using a screwdriver or power drill to tighten securely. Ensure that the straps hold the pipe firmly in place without over-tightening, which could damage the pipe.

Check that the pipe is adequately supported and does not have excessive movement. Repeat this process for all marked locations to ensure the pipe is adequately secured along its length.

Step 5: Inspect and Test the Installation

After securing the pipe straps, thoroughly inspect the installation to ensure all straps are firmly in place and the pipe is aligned correctly. Check for any signs of loose screws or gaps between the pipe and straps.

Once satisfied with the inspection, test the stability of the pipe by applying gentle pressure along its length. If the pipe shows any excessive movement, tighten the straps as needed. Completing this step ensures a reliable and sturdy installation that will last over time.

Step 6: Clean Up the Work Area

Once the installation is complete, gather and dispose of any debris, such as packaging, cut pipe pieces, or excess hardware. Use a broom or vacuum to clean the work area, ensuring it is safe and free of hazards.

Proper cleanup not only leaves the worksite tidy but also ensures no tools or materials are accidentally left behind. Double-check that all tools are accounted for and stored properly before finishing the job.

Step 7: Perform a Final Safety Check

Before considering the project complete, conduct a final safety check to ensure everything is secure and functioning correctly. Verify that all installed components are adequately tightened and aligned.

Ensure no sharp edges, protrusions, or potential hazards could pose a risk. If necessary, make any final adjustments or corrections. This last review step helps guarantee the installation’s safety and longevity.

Step 8: Keep a Record of the Installation

Maintaining a detailed record of the installation process is essential for future reference and troubleshooting. Document all components used, including their specifications, serial numbers, and installation locations.

Take photographs of critical stages of the installation, highlighting how parts were assembled and configured. Record any deviations from the original plan and note why those changes are made. Additionally, include the dates of installation and any testing or inspections conducted.

Proper documentation ensures that future maintenance, repairs, or upgrades can be carried out efficiently, saving time and reducing the likelihood of errors. This comprehensive record is a valuable resource for both the current team and any future personnel working with the installation.

Step 9: Consider Additional Support Measures

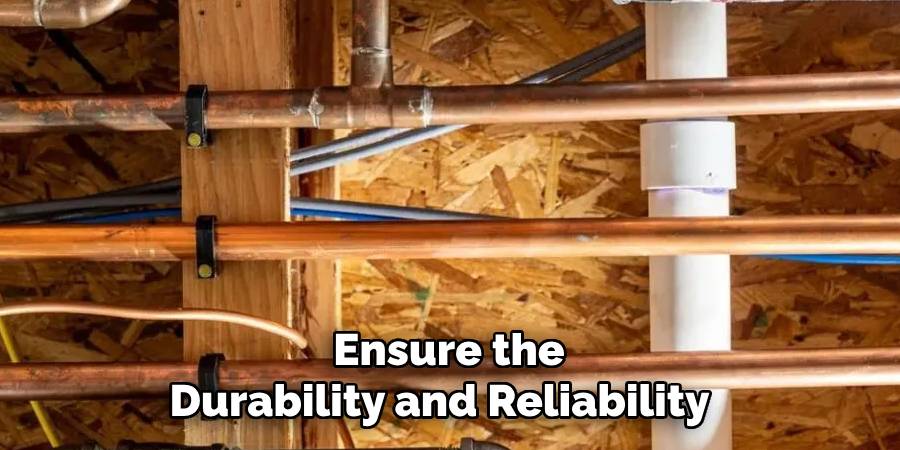

To ensure the durability and reliability of your plumbing system, consider implementing additional support measures. This could involve installing brackets, straps, or other forms of support to secure pipes and fittings, especially in areas prone to movement or vibration.

Insulating exposed pipes is another worthwhile measure, as it helps prevent heat loss, reduces condensation, and protects against freezing temperatures in colder climates.

Also, explore the use of surge protectors or pressure regulators to safeguard your system against unexpected water pressure fluctuations. By taking these extra precautions, you can minimize potential risks and extend the longevity of your plumbing installation effectively.

By following these steps and considering additional support measures, you can achieve a professional result in your plumbing installations.

5 Things You Should Avoid

- Using the Wrong Size Straps: Always ensure that the pipe straps you use are the correct size for securing the pipes. Using too large or too small straps can lead to instability and potential damage to the plumbing system.

- Over-Tightening the Straps: Tightening the straps excessively can damage the pipes, causing dents or restricting water flow. It’s essential to secure the straps snugly without putting too much pressure on the piping.

- Improper Strap Placement: Avoid placing the straps too far apart, as it can allow the pipes to sag or shift. Proper spacing is crucial to support the pipes effectively and prevent long-term issues.

- Skipping Anchors for Unsupported Walls: When attaching pipe straps to drywall or other unsupported surfaces, skipping appropriate wall anchors can lead to loose attachments and compromised stability.

- Using Non-Durable Materials: Avoid using low-quality or non-corrosion-resistant materials, especially in moisture-prone areas. Over time, these materials can degrade, leading to weakened support and potential plumbing failures.

By avoiding these common mistakes, you can ensure that your plumbing system remains in good condition and functions effectively.

Conclusion

Properly plumbing a pipe strap is essential to maintaining the integrity and longevity of your plumbing system.

You can prevent many common issues associated with improper pipe strapping by carefully selecting durable materials, ensuring secure yet gentle fastening, and adhering to correct spacing guidelines. Implementing these best practices helps avoid costly repairs, enhances stability, and promotes efficient water flow throughout your system. A well-executed installation ultimately contributes to your plumbing setup’s overall reliability and performance.

Hopefully, this guide on how to plumb pipe strap has provided you with valuable insights into the importance of proper pipe strapping and how to achieve it.