Do your copper pipes have a noticeable green hue? Are you noticing water pressure drops or incomplete drainage in certain fixtures of your home? If so, the culprit might be electrolysis – unwelcome corroding that can damage the lifespan and efficiency of copper plumbing.

Fortunately, there are methods you can implement to prevent electrolysis from ruining your piping system. Read on how to prevent electrolysis in copper pipes to learn more about how to reduce the risk of costly damage caused by electrolysis in copper pipes!

What is Electrolysis?

To put it simply, electrolysis is the process of a material corroding when in contact with another metal. In the case of copper piping, this occurs when two different types of metals are connected and water flows through them.

The reaction between the different metals and the water leads to an electrical charge being created, which causes corrosion or rusting on the outer surface of the pipes. This can be especially detrimental for homes with hard water, which contains a high concentration of minerals that make it more conducive and speeds up electrolysis.

How Does Electrolysis Affect Copper Pipes?

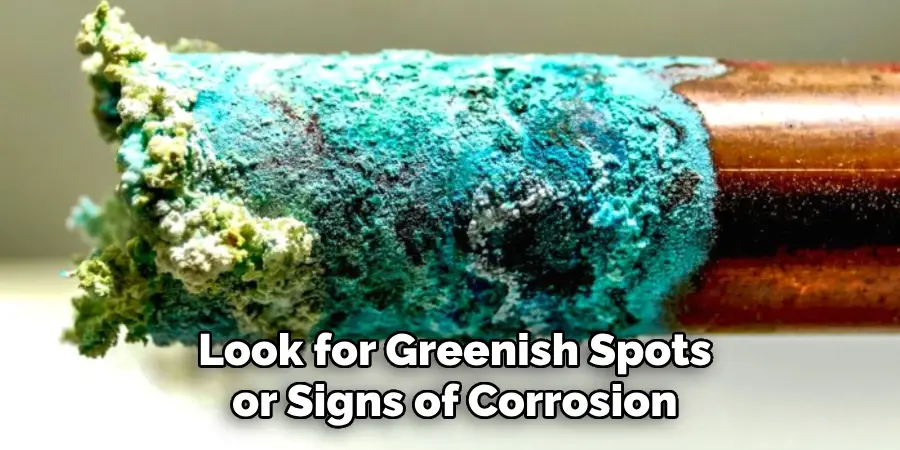

Electrolysis is a process where electrical energy is converted into chemical energy, leading to corrosion in copper pipes. If your home’s plumbing system uses copper for the supply and drainage of water, electrolysis can be an issue you need to address promptly. The effect of this electrochemical process on copper pipes results in green discoloration from the buildup of copper hydroxide and copper carbonate. Over time, this can lead to leaks and blockages, resulting in costly repairs or replacements.

Needed Materials

- Plumber’s Tape

- Rubber or Plastic Washers

- Dielectric Unions or Insulating Sleeves

- Water Softener System (Optional)

10 Step-by-step Guidelines on How to Prevent Electrolysis in Copper Pipes

Step 1: Turn Off the Water Supply

Begin by turning off the main shut-off valve to prevent any water from flowing through the pipes while you are working on them. It’s always better to err on the side of caution and ensure that no water is running through the pipes during this process. But if that’s not possible, make sure to wear proper protective gear and have a dry cloth nearby. You don’t want to get electrocuted or have water damage while trying to prevent electrolysis in your copper pipes.

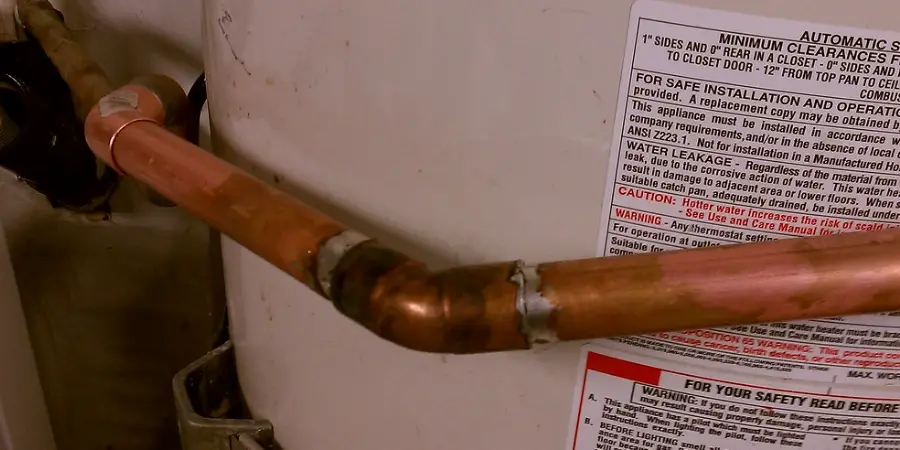

Step 2: Identify Problematic Areas

Inspect all visible copper pipes for greenish spots or any signs of corrosion. Pay special attention to joints and connections, as these are where different metals may be in contact with each other. These are the areas that are most prone to electrolysis. Take note of these areas and plan to implement prevention methods in those specific spots. It’s also a good idea to check for any leaks or blockages caused by electrolysis.

Step 3: Clean the Affected Areas

Once you have identified the problematic areas, clean them using a solution of vinegar and water. This will help remove any buildup of copper hydroxide and carbonate on the surface. Note that this is only a temporary solution and not a permanent fix for electrolysis in your copper pipes. You will still need to take preventive measures to stop it from happening in the future. But this step will help you see the extent of the damage and give you a clean surface to work on.

Step 4: Wrap Joints with Plumber’s Tape

For joints or connections that show signs of corrosion, wrap them with a plumber’s tape before connecting them back together. This will help prevent direct contact between different metals and minimize the risk of electrolysis occurring in those areas. It’s a simple, quick, and inexpensive solution that can prevent costly repairs in the long run.

Step 5: Use Rubber or Plastic Washers

Another way to create a barrier between different metals is by using rubber or plastic washers when connecting pipes. These materials are non-conductive and will serve as insulation between two different metals. Place these washers between joints or connections before connecting them back together. This will prevent any electrical charge from being created and reduce the risk of electrolysis.

Step 6: Install Dielectric Unions or Insulating Sleeves

For more severe cases of electrolysis, where pipes are in direct contact with each other, consider installing dielectric unions or insulating sleeves. These are specifically designed to separate different metals and prevent them from coming into contact with each other. They provide a permanent solution to preventing electrolysis in your copper pipes. However, keep in mind that these methods can be more costly and may require professional installation.

Step 7: Consider Installing a Water Softener System

As mentioned earlier, hard water is more conductive and can speed up the process of electrolysis. Consider installing a water softening system to reduce the mineral content in your home’s water supply. This will not only help prevent electrolysis but also has other benefits such as prolonging the lifespan of your appliances and improving soap lathering. Consult a professional plumber to determine the best water softener system for your home’s needs.

Step 8: Avoid Using Galvanized Fittings

Galvanized fittings are made of iron or steel and have a zinc coating. When in contact with copper pipes, this can accelerate electrolysis due to the combination of different metals. As much as possible, avoid using galvanized fittings when connecting copper pipes. Stick to using copper fittings or those made of the same material to prevent any chemical reactions that can lead to electrolysis.

Step 9: Regularly Inspect and Maintain

Once you have implemented preventive measures, it’s essential to regularly inspect and maintain your copper pipes. Check for any signs of corrosion or leaks and address them promptly. Keep an eye out for the areas you identified as problematic in step two and make sure the prevention methods are still intact. By being proactive, you can save yourself from costly repairs or replacements in the future.

Step 10: Seek Professional Help if Needed

If you are unsure of how to prevent electrolysis in your copper pipes or think the damage is beyond DIY repair, seek professional help. A licensed plumber will have the knowledge and experience to assess the situation and provide the best solution for your specific plumbing system. Don’t hesitate to reach out for assistance if needed. It’s better to be safe than sorry when it comes to the integrity of your home’s plumbing system.

Following these ten steps on how to prevent electrolysis in copper pipes can help prevent electrolysis in your copper pipes and save you from potential plumbing disasters. It’s always better to take preventive measures rather than deal with the consequences later on.

By keeping an eye on your plumbing system and implementing these prevention methods, you can ensure that your copper pipes will last for many years to come without any issues caused by electrolysis. Remember, prevention is key!

Frequently Asked Questions

Q1: What is Electrolysis in Copper Pipes?

A: Electrolysis in copper pipes is a process where electricity flows through different metals in contact with each other, causing them to corrode. This can cause leaks and blockages in your home’s plumbing system.

Q2: How can I identify if my copper pipes have electrolysis?

A: Look for greenish spots or signs of corrosion on visible copper pipes. Pay special attention to joints and connections, as these are the areas most prone to electrolysis.

Q3: Can I fix electrolysis in my copper pipes myself?

A: Yes, you can fix electrolysis yourself by following the steps outlined above. However, it’s always best to consult a professional if you are unsure or if the damage is severe. It’s better to be safe than sorry when it comes to your home’s plumbing system.

Q4: Are there any long-term solutions for preventing electrolysis in copper pipes?

A: Yes, using dielectric unions or insulating sleeves and regularly maintaining your pipes can provide long-term solutions for preventing electrolysis. It’s also recommended to install a water softening system to reduce the mineral content in your water supply. Keep in mind that these methods may require professional installation.

Conclusion

Ultimately, there are numerous ways to take action to prevent electrolysis in copper pipes, ranging from simple steps that you can do yourself to preventative maintenance work that should be undertaken by professionals.

This is a problem that can cause major damage, so it is important not to take any chances. Keeping an eye on corroding pipes and regularly inspecting your water system is essential.

Targeting the source of the corrosion and taking tangible steps such as replacing old galvanized pipes or re-grounding the electrical wiring can be crucial in protecting your plumbing and avoiding costly repairs down the line. In short on how to prevent electrolysis in copper pipes, don’t let electrolysis compromise the safety of your home – invest in regular maintenance today to ensure peace of mind tomorrow.