An end cap is a crucial component used to seal or close off the end of a tube, pipe, or similar structure. It is essential in various applications, including plumbing systems, furniture design, automotive parts, and industrial equipment. End caps come in different materials, such as plastic, metal, or rubber, each suited for specific environments and purposes. Their primary function is to prevent leaks, ensure stability, and protect the structure from external damage.

However, end caps are often exposed to environmental factors such as moisture, UV rays, and physical wear, which can lead to degradation over time. Understanding how to protect end cap components is vital to ensuring their longevity, functionality, and efficiency. Methods such as using UV-resistant materials, applying protective coatings, and regular maintenance can significantly enhance their durability. Proper protection prevents damage and saves costs in replacements and repairs.

Understanding End Caps and Their Uses

What is an End Cap?

An end cap is a cover or closure placed at the end of a pipe, furniture leg, or industrial equipment to seal and protect it. These components serve various functional and aesthetic purposes across different industries.

Common Types of End Caps

Plumbing End Caps: These caps are designed to seal the ends of pipes and prevent leaks in residential, commercial, or industrial plumbing systems.

Furniture End Caps: Used primarily to cover the legs of chairs, tables, or other furniture, they protect floors from scratches and damage while enhancing the overall appearance.

Automotive End Caps: Found in vehicle exhaust systems and tubing, automotive end caps help regulate airflow and provide durability under extreme conditions.

Industrial End Caps: These are often used to cover machinery components and electrical connections, protecting them from dust, moisture, and other contaminants.

Why End Caps Need Protection

End caps are exposed to environmental stressors such as UV rays, moisture, and physical wear. They may crack, rust, or deteriorate over time without proper protection, compromising their functionality. Using durable materials, applying protective coatings, and performing routine inspections help extend the lifespan of pipes, furniture, and industrial equipment, reducing long-term maintenance costs.

Materials and Tools Needed

Basic Protection Materials

- Rubber or Plastic Protective Caps: Ideal for covering end caps in residential and light-use applications to prevent damage and wear.

- Sealants: Silicone, epoxy, or waterproof tape can create a watertight seal, protecting end caps from moisture and leaks.

- Paint or Corrosion-Resistant Coatings: Used to guard against rust and environmental degradation, ensuring the longevity of metal end caps.

For Heavy-Duty Protection

- Metal End Caps with Rustproof Coating: Designed for industrial and high-pressure environments, offering robust protection against wear and corrosion.

- Reinforced Rubber Caps: Suitable for heavy machinery and equipment, providing added durability and resistance to extreme conditions.

Tools Required

- Wrench: Necessary for tightening or securing end caps, particularly in plumbing applications.

- Sandpaper: Used to prepare surfaces by smoothing out rough edges or removing old coatings before applying new protection.

- Protective Gloves and Safety Goggles: Essential for ensuring safety when handling tools and materials, especially when dealing with chemicals or sharp objects.

How to Protect End Cap: Sealing and Coating End Caps for Longevity

Properly sealing and coating end caps ensures their durability and performance over time. This process involves a few straightforward steps to create a protective barrier against environmental factors such as moisture, rust, and wear.

Step 1: Clean the End Cap Surface

Start by wiping the end cap surface with a clean, dry cloth. This removes dust, dirt, and grease that could interfere with the adhesion of the sealant or coating.

Step 2: Apply a Waterproof Sealant

Using a silicone or epoxy sealant, apply an even layer over the surface of the end cap. This step creates a watertight barrier that protects against leaks and moisture penetration.

Step 3: Add a Corrosion-Resistant Coating

For metal end caps, enhance protection by applying a rust-resistant paint or powder coating. This additional layer prevents oxidation and protects against harsh environmental conditions.

Step 4: Allow Proper Drying

It’s crucial to allow sufficient drying time for both the sealant and the coating. Follow product instructions to ensure the materials cure properly before exposing the end cap to heavy use or extreme conditions.

How to Protect End Cap: Using Protective Covers for Extra Durability

Step 1: Choose a Rubber or Plastic End Cap Cover Based on Size and Material

Select a durable rubber or plastic cover that matches the size and material of your end cap. These covers provide an extra layer of protection while accommodating specific environmental demands. Rubber covers offer flexibility and shock absorption, while plastic covers are ideal for resisting wear in less rugged conditions.

Step 2: Fit the Cover Securely Onto the End Cap to Prevent Slipping

Once you’ve chosen the appropriate cover, ensure it fits snugly over the end cap. A proper fit is crucial to prevent any slipping or misalignment that could expose the end cap to damage or reduce protection efficiency. Double-check the size and positioning for a seamless application.

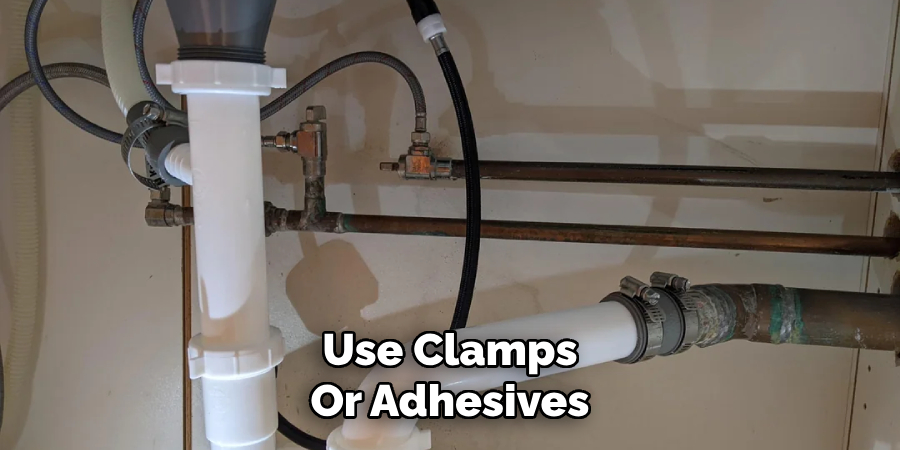

Step 3: Use Clamps or Adhesives for Added Security in High-Impact Areas

For environments subject to heavy use or frequent impacts, reinforce the attachment of the protective cover. Utilize clamps or adhesive bonds to secure the cover firmly in place. This added precaution ensures the cover remains stable, even under challenging conditions, extending the life of the end cap.

Step 4: Replace Covers Periodically to Maintain Protection

Protective covers can experience wear and tear over time, especially in demanding environments. Regularly inspect the covers for cracks, looseness, or damage, and replace them as needed to maintain optimal protection and durability. Timely replacement will safeguard the underlying end cap and ensure consistent performance.

Reinforcing End Caps for Outdoor or Heavy-Use Areas

Step 1: Select Heavy-Duty Metal or Reinforced Rubber Caps for Extreme Conditions

For outdoor or heavy-use applications, choose end caps made from robust materials such as stainless steel, aluminum, or reinforced rubber. These materials offer superior durability, withstanding harsh elements like high impact, heavy loads, and extreme temperatures. Their resilience ensures long-lasting performance in demanding environments.

Step 2: Secure the Cap with a Locking Mechanism or Screws

To ensure the end cap stays firmly in place, use a locking mechanism, such as snap-fit design, or secure it with screws. This prevents the cap from loosening or detaching due to vibrations, impacts, or other external forces. Be sure to use fasteners that are also corrosion-resistant for outdoor applications.

Step 3: Apply a Weatherproofing Layer

If the end cap will be exposed to rain, heat, or chemicals, add an extra layer of protection with a weatherproof coating or sealant. This might include UV-resistant layers for sun exposure, chemical-resistant coatings for harsh industrial environments, or waterproof sealants to ensure no moisture penetration.

Step 4: Inspect and Maintain Regularly to Prevent Wear

Regular inspections are conducted to maximize the lifespan of the reinforced end cap. Check for signs of wear, corrosion, or damage, and reapply protective layers if necessary. By addressing potential issues early, you can prevent costly repairs and ensure the end cap performs effectively in demanding conditions.

Common Mistakes and Troubleshooting

Using Incorrect Materials

One of the most common mistakes is selecting an end cap made from materials that cannot withstand the specific demands of the application. Weak materials may wear out quickly, leading to premature failure. Always choose durable, corrosion-resistant materials and suitable for the environment where the end cap will be used.

Neglecting Regular Maintenance

Failing to perform regular inspections and maintenance can result in unnoticed cracks, rust, or other forms of wear. These issues often escalate over time, leading to structural weaknesses or functionality problems. Regular checks and timely repairs are essential to prevent costly failures.

Not Securing the End Cap Properly

An improperly installed end cap can become loose or detach entirely, potentially causing leaks or damaging the structure. Ensure the cap is fastened securely using the appropriate mechanism, such as screws, adhesive, or snap-fit designs, depending on the application.

Ignoring Environmental Factors

Overlooking environmental considerations, such as high humidity, extreme heat, or chemical exposure, can lead to accelerated wear and tear. Always select protective coatings or weatherproofing measures tailored to the end cap’s specific conditions, ensuring longevity and reliability.

Maintenance Tips for Long-Term Protection

Proper maintenance is critical for ensuring the longevity and reliability of your end caps. Follow these tips to prevent damage and maintain optimal performance:

Regular Inspections

Make it a habit to inspect your end caps every few months for signs of cracks, rust, or other wear. Spotting issues early can help you address them before they worsen, saving time and money in the long run.

Cleaning Routine

Establish a regular cleaning routine to remove dirt, debris, or other contaminants that may accumulate on the caps over time. Use a soft cloth or brush along with appropriate cleaning agents to safeguard the material’s integrity.

Replacing Worn-Out Caps

If an end cap appears damaged, loose, or compromised, replace it promptly. Continuing to use a worn-out cap could lead to leaks, instability, or further structural damage.

Using UV-Resistant and Corrosion-Resistant Materials

For outdoor applications, it is essential to choose end caps made from UV-resistant and corrosion-resistant materials. These materials withstand harsh environmental conditions better, ensuring the caps remain durable and functional despite prolonged exposure to sunlight, moisture, or other corrosive factors.

Consistent maintenance practices will protect your components and extend the lifespan of your end caps for years to come.

Conclusion

Understanding how to protect end cap components is vital for maintaining durability and efficiency in various applications. Properly sealing end caps, using protective covers, and employing reinforced designs for heavy-duty purposes are among the most effective safeguards. Additionally, choosing UV-resistant and corrosion-resistant materials further enhances their resilience against environmental factors. Regular cleaning routines and prompt replacement of worn-out caps help prevent potential damage and ensure ongoing reliability. By following these maintenance practices, you can significantly extend the lifespan of your end caps, ensuring long-term performance and cost-effectiveness for your equipment or structures.