Water pumps are an essential component in the functioning of many machines, ranging from cars and trucks to boats and lawn mowers. They work by circulating coolant or water through the engine to help regulate its temperature and prevent it from overheating. Over time, these pumps can wear out or fail due to normal wear and tear, leading to potential engine damage. In such cases, knowing to rebuild a water pump can save you time and money compared to purchasing a new one.

The main advantage of rebuilding a water pump is that it can save you time and money. Water pumps are an essential component in any vehicle’s cooling system, and over time, they may wear out or fail. Rather than replacing the entire pump, which can be expensive, learning how to rebuild it allows you to fix the issue yourself at a fraction of the cost. Read this blog post to learn how to rebuild a water pump.

Tools You Will Need

- A new water pump

- New gaskets (for the water pump and any other connections)

- Clean rags

- Basic wrench set

- Screwdriver set

- Gasket scraper or putty knife

- Cooling system flushing agent

- Antifreeze/coolant mixture

- Gasket sealant

- Torque wrench

Rebuilding a water pump is essential to ensure the proper functioning of your vehicle’s cooling system. It may seem like a daunting task, but with the right tools and knowledge, it can be done easily.

Step by Step Processes for How to Rebuild a Water Pump

Step 1: Inspect the Water Pump

Before rebuilding your water pump, it is important to first inspect it carefully. Look for any signs of damage such as cracks or leaks. Also check if there are any loose or broken components that may need replacement. This will give you an idea of what parts you need to purchase for the rebuild.

Step 2: Gather Necessary Tools and Materials

Gather all the necessary tools and materials needed for the process. You will likely need wrenches, screwdrivers, pliers, gasket sealant, and a water pump rebuild kit specific to your make and model of car. It is important to have all the tools and materials ready before starting the rebuild.

Before removing the water pump, you need to drain the coolant from your car’s radiator. You can do this by locating the radiator drain plug and opening it while your engine is cold. Catch the coolant in a container for proper disposal. This will prevent any spills or leaks during the rebuild.

Step 3: Remove the Water Pump

Using your tools, remove the water pump from your engine. This may require removing other components such as belts and hoses. Be sure to reference your car’s manual for specific instructions on how to properly remove the water pump. Once removed, clean the surface where the water pump was attached to for a smooth rebuild.

Carefully disassemble the water pump, paying attention to how each component is positioned. Take note of any damaged parts that need replacement. It is also recommended to take photos or make sketches to help with reassembly later on.

Step 4: Clean and Inspect Each Component

Thoroughly clean each component of the water pump using a degreaser. Inspect for any damage or wear and replace as needed. Check the gasket for signs of wear and tear, as this is a common cause of water pump failure.

Following the instructions provided in your rebuild kit, reassemble the water pump with the new components. It is important to follow each step carefully to ensure proper installation. Use gasket sealant on both sides of the gasket for a secure fit.

Step 5: Install the Rebuilt Water Pump

Carefully install the rebuilt water pump back into your engine, making sure all components are properly aligned. Use new bolts and tighten them according to the recommended torque specifications for your car’s make and model.

Once the water pump is securely installed, refill the radiator with fresh coolant. Be sure to follow the proper ratio of antifreeze to water for your specific climate.

Step 6: Test and Monitor

Start the engine and let it run for a few minutes while monitoring for any leaks or abnormal noises. If everything looks good, take your car for a test drive to ensure the water pump is functioning properly. It is also recommended to regularly check and monitor the water pump for any signs of wear or damage to prevent future issues.

Safety Precautions for How to Rebuild a Water Pump

- Wear appropriate safety gear such as gloves, goggles and a dust mask to protect yourself from any potential hazards during the rebuilding process.

- Always make sure that you are working in a well-ventilated area to avoid inhaling harmful fumes or gases that may be emitted from the pump or cleaning solutions.

- Disconnect the power source and make sure the pump is completely drained of any liquids before beginning the rebuilding process.

- Use a lockout/tagout system to ensure that no one accidentally turns on the pump while it is being rebuilt.

- Handle all parts with care, especially smaller ones that may be easily lost or damaged. Keep track of all pieces and label them accordingly to avoid confusion during reassembly.

- Use proper tools and techniques when disassembling and reassembling the pump to prevent injury or damage to the pump. It is important to follow the manufacturer’s instructions and diagrams closely.

- If you are unsure about any step of the rebuilding process, consult a professional or refer to the pump’s manual for guidance.

By following these safety precautions, you can ensure a smooth and safe rebuilding process for your water pump. Remember to always prioritize your safety and take necessary precautions while working with any machinery.

What Are the Common Signs of a Malfunctioning Water Pump?

The water pump is a crucial component of your vehicle’s cooling system, responsible for keeping the engine at an optimal running temperature. When it starts to malfunction, it can cause significant damage and result in expensive repairs if not addressed promptly. In this section, we will discuss the common signs of a malfunctioning water pump.

1. Overheating Engine

One of the most obvious signs of a failing water pump is an engine that is constantly running hot. This can be caused by a lack of coolant flow due to a malfunctioning water pump. If left unaddressed, it can result in serious damage to your engine.

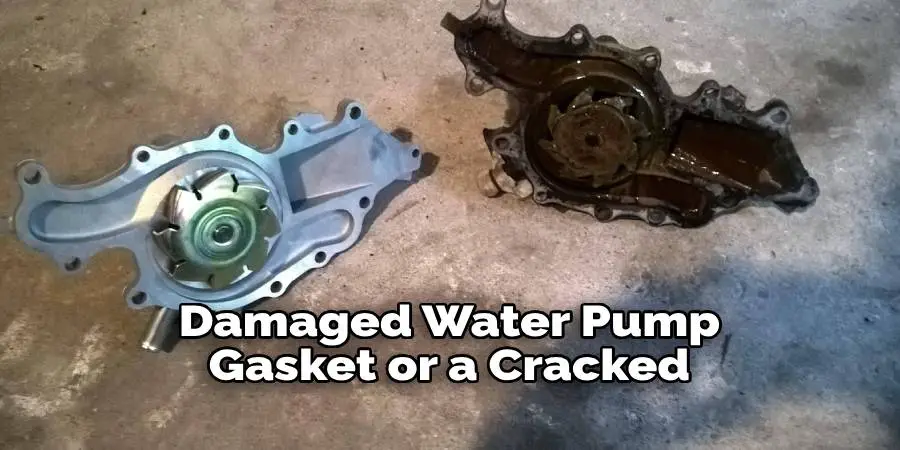

2. Leaking Coolant

A damaged water pump gasket or a cracked housing can cause coolant to leak out of the water pump. If you notice puddles of green, orange, or pink fluid under your vehicle, it could be a sign that your water pump needs to be rebuilt.

3. Unusual Noises

A faulty water pump can produce abnormal noises, such as grinding or whining sounds. These noises are caused by loose bearings, which indicate that your water pump may need to be rebuilt.

4. Engine Pulley Wobbling

The engine pulley is connected to the water pump through a belt, and if it starts to wobble or show signs of wear and tear, it could indicate that the water pump needs to be rebuilt.

Steam or Smoke from the Engine: If your engine is emitting steam or smoke, it could be a sign of a severe overheating issue due to a malfunctioning water pump. This requires immediate attention and could potentially lead to engine failure if not addressed promptly.

What Are Some Common Mistakes to Avoid When Rebuilding a Water Pump?

Rebuilding a water pump can be a daunting task, especially for those who are not familiar with the process. It requires a certain level of mechanical knowledge and skill to successfully rebuild a water pump without causing any damage. Even for experienced individuals, there are some common mistakes that can occur during the rebuilding process. In this section, we will discuss some of these mistakes and how to avoid them.

1. Lack of Preparation

One of the biggest mistakes made when rebuilding a water pump is not properly preparing for the task. Before beginning the process, it is important to gather all necessary tools and replacement parts. This includes gaskets, seals, bearings, and any other components that may need to be replaced.

It is also important to thoroughly clean the water pump before beginning the rebuild, as any debris or buildup can cause issues with the new components. Additionally, it is important to refer to the manufacturer’s instructions or a trusted guide to ensure that all steps are followed correctly.

2. Incorrect Assembly

Another common mistake is incorrectly assembling the water pump. This can happen if all of the components are not properly aligned or if they are not tightened to the correct torque specifications. It is important to carefully follow the assembly process outlined in the manufacturer’s instructions or a reliable guide. Double-checking and ensuring that all parts are in their proper places can also prevent this mistake from occurring. Additionally, using a torque wrench to tighten bolts to the correct specification is crucial.

3. Skipping Steps

Rebuilding a water pump can be a lengthy process and it may be tempting to rush through it. However, skipping steps can lead to issues with the rebuilt water pump. It is important to follow all steps carefully and not take any shortcuts. This includes properly lubricating moving parts, checking for any leaks before reassembling the pump, and testing the finished product before installing it back into the vehicle. Skipping steps can result in the pump not functioning properly or even causing damage to the engine.

4. Not Replacing All Necessary Parts

When rebuilding a water pump, it is important to replace all necessary parts. This includes not only obvious components like gaskets and seals, but also smaller pieces such as o-rings and washers. These small components may seem insignificant, but they play an important role in the overall function of the water pump. By replacing all necessary parts, you can ensure that your rebuilt water pump will function properly and avoid any issues down the road.

Conclusion

In conclusion, rebuilding a water pump is not a task to be taken lightly. It requires proper preparation, careful assembly, and attention to detail in order to avoid common mistakes that can occur. By following all steps correctly and replacing all necessary parts, you can ensure that your rebuilt water pump will function properly and efficiently.

While it may seem like a daunting task at first, with the right knowledge and tools, anyone can successfully rebuild a water pump. So don’t be afraid to take on this challenge and keep your vehicle running smoothly for years to come. I hope this article has been beneficial for learning how to rebuild a water pump. Make Sure the precautionary measures are followed chronologically.