Sealing hydraulic fittings is a critical task in maintaining the efficiency and safety of hydraulic systems, which are widely used in industrial, automotive, and heavy machinery applications. Properly sealed hydraulic fittings prevent fluid leaks, maintain system pressure, and ensure optimal performance, thereby reducing the risk of equipment failure and costly downtime. Achieving a reliable seal involves understanding the types of fittings and seals, the materials involved, and the correct installation procedures.

This includes selecting the appropriate sealant, preparing the fittings, and applying the sealant with precision. Whether you are dealing with metal-to-metal seals, O-rings, or Teflon tape, each method requires specific techniques to ensure durability and effectiveness. This guide will walk you through the essential steps and best practices for how to seal hydraulic fittings, helping you to achieve a leak-free and reliable hydraulic system.

Importance of Proper Sealing in Hydraulic Systems

Proper sealing in hydraulic systems is paramount to their overall reliability and performance. Inadequate or faulty sealing can lead to fluid leaks, which not only diminish the efficiency of the system but can also cause significant damage to components and create hazardous working conditions. Leaks can result in loss of hydraulic fluid, leading to lowered system pressure, reduced power output, and increased wear and tear on the machinery.

Additionally, fluid leaks pose environmental risks by contaminating the surroundings with hydraulic oils, potentially resulting in costly clean-up and legal ramifications. Ensuring tight, effective seals mitigates these risks, promotes consistent system performance, and extends the lifespan of hydraulic equipment. Ultimately, proper sealing is essential for maintaining the safety, efficiency, and environmental integrity of hydraulic systems.

10 Methods How to Seal Hydraulic Fittings

1. Proper Torque Application

Applying the correct torque to hydraulic fittings is crucial for achieving an optimal seal. Over-tightening or under-tightening can lead to leaks, damage to fittings, or even catastrophic system failures. The torque specification for each fitting type and size is usually provided by the manufacturer and must be followed meticulously.

To apply the correct torque, use a calibrated torque wrench and follow a star pattern for multi-bolt connections to ensure even distribution of force. Always clean the threads and mating surfaces before tightening to remove any debris or contaminants that could compromise the seal. Gradually tighten the fitting to the specified torque, checking for alignment and avoiding any cross-threading.

2. Using Teflon Tape

Teflon tape, also known as PTFE tape, is a popular sealing material for hydraulic fittings, particularly in low-pressure applications. To use Teflon tape effectively, begin by cleaning the threads thoroughly. Wrap the tape around the male threads in a clockwise direction, starting at the base and working towards the tip, ensuring that each layer overlaps slightly.

Typically, two to three wraps are sufficient. Avoid covering the first thread to prevent tape fragments from entering the hydraulic system. Tighten the fitting as per the manufacturer’s torque recommendations. The Teflon tape acts as a lubricant during tightening and fills the thread gaps, creating a reliable seal.

3. Pipe Dope Application

Pipe dope, or thread sealant compound, is another effective method for sealing hydraulic fittings, particularly in high-pressure environments. When selecting a pipe dope, ensure it is compatible with the hydraulic fluid and operating temperature range.

Apply a thin, even layer of the sealant to the male threads using a brush or applicator, avoiding excess that could contaminate the hydraulic system. Assemble the fitting and tighten it to the specified torque. Pipe dope fills the voids between threads, providing a robust seal that is resistant to vibration and pressure fluctuations.

4. O-Rings and Backup Rings

O-rings are widely used in hydraulic fittings for their excellent sealing properties. Choosing the correct O-ring material is essential, considering factors such as hydraulic fluid compatibility, temperature, and pressure. Common materials include nitrile, Viton, and EPDM. Inspect the O-ring for any damage or defects before installation.

Lubricate the O-ring with a compatible hydraulic fluid to facilitate assembly and prevent pinching. For high-pressure applications, use backup rings in conjunction with O-rings to prevent extrusion. Backup rings are typically made of PTFE or nylon and should be placed on the low-pressure side of the O-ring.

5. Thread Lockers

Thread lockers are anaerobic adhesives that cure in the absence of air and in the presence of metal ions, providing a secure and leak-proof seal for hydraulic fittings. Choose the appropriate strength thread locker based on the application’s requirements—low, medium, or high strength. Clean the threads thoroughly to remove any oil or contaminants.

Apply a small amount of thread locker to the male threads and assemble the fitting. The adhesive fills the gaps between threads, creating a strong bond that resists vibration and thermal cycling. Allow sufficient curing time as specified by the manufacturer before pressurizing the system.

6. Flared Fittings

Flared fittings are designed to provide a secure seal without the need for additional sealing materials. The sealing is achieved through metal-to-metal contact between the flared end of the tube and the fitting body. To create a proper flare, use a flaring tool that matches the tubing material and size. Cut the tube end squarely and deburr it to remove any sharp edges. Insert the tube into the flaring tool and create a uniform flare.

Ensure the flare is free from cracks or distortions. Assemble the fitting and tighten to the recommended torque, ensuring the flare seats properly against the fitting body to achieve a leak-proof seal.

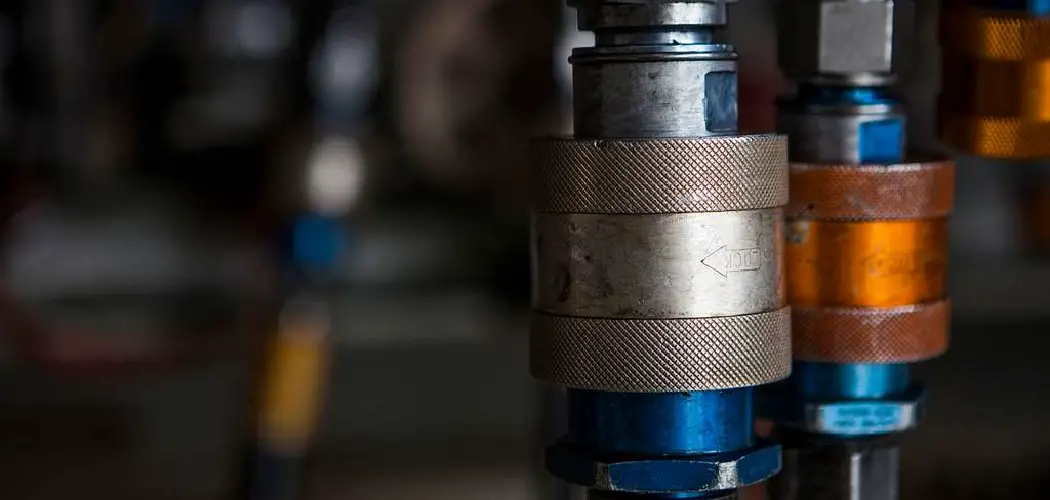

7. Compression Fittings

Compression fittings are another reliable method for sealing hydraulic connections, especially in high-pressure applications. These fittings consist of a nut, a ferrule (or compression ring), and a fitting body. To assemble a compression fitting, insert the tube into the fitting body until it bottoms out. Slide the nut and ferrule onto the tube and finger-tighten the nut.

Using a wrench, tighten the nut a specified number of turns, typically one and a quarter to one and a half, depending on the manufacturer’s recommendations. This compresses the ferrule onto the tube, creating a secure metal-to-metal seal that is resistant to vibration and pressure.

8. Sealants for Face Seals

Face seal fittings use an O-ring or gasket to achieve a leak-proof seal between two flat surfaces. These fittings are commonly used in high-pressure hydraulic systems. To ensure a proper seal, select an O-ring or gasket material compatible with the hydraulic fluid and operating conditions.

Clean the sealing surfaces thoroughly to remove any debris or contaminants. Place the O-ring or gasket in the groove on the fitting face and lubricate it with a compatible fluid. Assemble the fittings and tighten to the specified torque, ensuring the sealing surfaces are aligned correctly. The O-ring or gasket will compress to fill any imperfections in the sealing surfaces, creating a robust seal.

9. Swaged Fittings

Swaged fittings provide a permanent and reliable seal for hydraulic systems, particularly in high-pressure applications. These fittings require specialized equipment to deform the fitting body and tubing, creating a strong mechanical bond. To install a swaged fitting, insert the tube into the fitting body and position it correctly.

Use a swaging tool to apply pressure and deform the fitting onto the tube. This process creates a leak-proof seal by cold-working the metal, enhancing the mechanical strength and sealing capability. Swaged fittings are ideal for applications where disassembly is not required, as they provide a permanent connection.

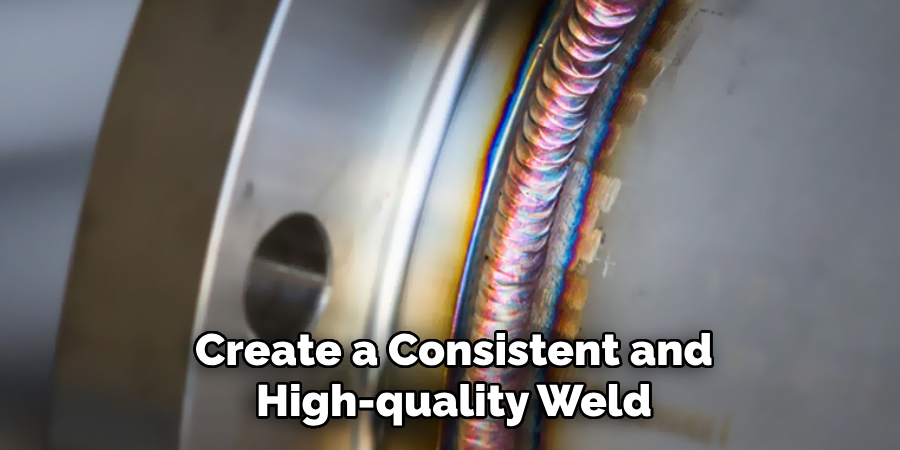

10. Orbital Welding

Orbital welding is a highly precise and reliable method for sealing hydraulic fittings, particularly in applications requiring high purity and minimal contamination. This technique involves using an automated welding system to create a consistent and high-quality weld between the tube and fitting. To perform orbital welding, clean the tube and fitting surfaces thoroughly to remove any contaminants.

Position the tube and fitting in the welding fixture and align them correctly. Program the orbital welding machine with the appropriate parameters, including welding speed, current, and gas flow. Initiate the welding process, allowing the machine to perform a 360-degree weld around the tube, creating a seamless and leak-proof connection. Orbital welding is commonly used in industries such as aerospace, pharmaceuticals, and food processing, where precision and cleanliness are paramount.

Conclusion

Sealing hydraulic fittings effectively requires a combination of proper technique, appropriate materials, and meticulous attention to detail. Each method described above offers unique advantages and is suitable for different applications and operating conditions. Whether using Teflon tape for low-pressure systems or orbital welding for high-purity environments, understanding the principles and best practices of each sealing method is essential for maintaining the integrity and reliability of hydraulic systems.

By following these comprehensive guidelines, technicians and engineers can ensure leak-free connections, enhance system performance, and prolong the lifespan of hydraulic components. Now that you know how to seal hydraulic fittings. While it does take a few steps each time, hopefully now you understand the process and why it’s worth taking the extra step to make sure your floor is properly cared for. So don’t wait any longer, take action today!