The importance of proper furnace sizing cannot be overstated when planning efficient and cost-effective heating for any building. Choosing the right size furnace is crucial to ensure comfortable indoor temperatures, reduce energy consumption, and avoid unnecessary wear and tear on your heating system.

The process of how to size a furnace involves a comprehensive analysis of your building’s heating requirements. This includes calculating the heating load, assessing building characteristics, understanding climate conditions, and considering the efficiency of potential furnaces.

The purpose of this article is to provide a detailed guide on how to size a furnace effectively. By covering everything from basic definitions to advanced calculation methods, we aim to equip homeowners, builders, and HVAC professionals with the knowledge needed to make informed decisions about furnace sizing.

The scope of this article encompasses all steps of the furnace sizing process, ensuring readers have a clear roadmap for selecting a heating system that meets their specific needs.

Understanding Heating Load Calculation

A. Definition and Significance of Heating Load

The concept of heating load refers to the total amount of heat energy required to maintain the internal temperature of a building at a comfortable level during the coldest seasons. Determining the heating load is a fundamental step in the process of how to size a furnace, as it directly influences the capacity of the heating system needed.

The significance of accurately calculating the heating load cannot be overstated, as it ensures that the chosen furnace will be capable of providing sufficient heat without being excessively large, thereby optimizing energy use and minimizing costs.

B. Factors Affecting Heating Load Calculation

Several factors play a crucial role in determining a building’s heating load, including but not limited to:

- Building Size and Construction: Larger spaces require more heat, while the materials used in construction can affect heat retention.

- Insulation Quality: Better-insulated buildings retain heat more efficiently, thus reducing the heating load.

- Window and Door Efficiency: The type, size, and insulation properties of windows and doors can significantly impact heat loss.

- Occupancy and Usage Patterns: Buildings with higher occupancy or those that are used more frequently may have higher heat requirements.

- Local Climate Conditions: Colder regions with lower temperatures and higher wind speeds increase the heating load.

C. Methods for Calculating Heating Load

Calculating the heating load accurately is essential for efficient furnace sizing. The most widely recognized methods include:

- Manual J Calculation: This comprehensive approach takes into account all aspects of the building’s characteristics, including layout, construction materials, insulation, window types, and local climate conditions.

- Software Tools: Various software solutions offer a more automated approach to heating load calculations, incorporating databases of climate data and building materials.

- Simplified Estimations: For smaller or less complex buildings, simplified methods can provide a rough estimate of the heating load, although they may not be as precise as the Manual J calculation.

Understanding the complexity and importance of heating load calculation highlights the necessity of thorough evaluation and analysis when sizing a furnace. This foundational step ensures that the heating system is neither too large nor too small, balancing comfort with efficiency and cost-effectiveness.

Assessing Building Characteristics

Evaluating the size and layout of a building is the primary step in determining the appropriate furnace size. The larger the area that requires heating, the greater the heating capacity needed.

Layout complexity, such as multiple floors or wings, also affects how heat is distributed and, thus, the type of furnace that will be most effective.

A. Evaluating Building Size and Layout

Understanding the total square footage and the specific layout of a building is crucial.

High ceilings, open spaces, and extended corridors can influence how heat circulates and may necessitate a more powerful heating solution. Additionally, the orientation of the building and the presence of a basement or attic can impact heating requirements.

B. Considering Insulation Levels and Thermal Efficiency

Insulation plays a pivotal role in maintaining heat within a building, directly influencing the heating load.

A well-insulated building requires a smaller furnace than a poorly insulated building of the same size. Evaluating the R-values of insulation in the walls, floors, and ceiling provides a metric of the building’s overall thermal efficiency.

C. Identifying Windows, Doors, and Ventilation Systems

Windows and doors can be significant sources of heat loss, especially if they are old, improperly sealed, or if the glass is not double-glazed. The size, type, and quality of these components should be considered in the heating load calculation.

Additionally, the building’s ventilation system affects heat retention and distribution; modern, energy-efficient systems can reduce the heating load by recirculating warm air and minimizing heat loss.

Climate Considerations

Climate plays a significant role in determining the appropriate size of a furnace. Different regions experience varying weather patterns, temperatures, and humidity levels, all of which impact a building’s heating requirements.

Understanding these variables is essential to selecting a heating system that can efficiently and effectively maintain comfortable indoor temperatures throughout the cold months.

A. Understanding Regional Climate Conditions

Regional climate conditions vary greatly, from the cold, harsh winters of the northeast to the milder, damp conditions of the Pacific Northwest. In areas prone to extreme cold, furnaces must have a higher capacity to ensure adequate heating.

Conversely, regions with milder winters may require less powerful systems. The local climate not only influences the type of furnace but also guides the level of insulation and weatherproofing needed.

B. Factoring in Outdoor Temperatures and Humidity Levels

Outdoor temperatures and humidity levels directly affect a building’s heating load. Cold air outside increases heat loss through the building envelope, requiring more energy to maintain indoor warmth.

Conversely, high humidity can make the air feel colder than it actually is, potentially necessitating additional heating capacity to achieve comfort. A furnace must be sized with these factors in mind to accommodate the coldest temperatures and highest humidity levels typically experienced in the region.

C. Calculating Heating Degree Days

Heating degree days (HDD) is a measurement designed to quantify the demand for energy needed to heat a building. It is calculated by subtracting the average daily outdoor temperature from a base temperature, typically 65°F (18°C), for each day that the average is below the base.

The sum of these differences over a heating season gives the total HDD. This figure helps understand the extent of heating required over a season and aids in accurately sizing a furnace.

Regions with a higher HDD value will generally require a furnace with a greater capacity than those in areas with a lower HDD count.

Calculating Heating Load

The process of calculating the heating load is a crucial step in ensuring a home or building is equipped with a heating system that sufficiently meets its needs without overextension or wastage of resources. This section further explores the methodologies and considerations involved in this process.

A. Using the Manual J Method for Load Calculation

The Manual J calculation method stands as the industry standard for determining the heating (and cooling) loads of residential buildings.

This method involves a detailed analysis that considers various factors, including but not limited to the building’s orientation, insulation quality, window and door types, and even the local climate.

By inputting precise data about the building’s characteristics and the environmental conditions, it’s possible to calculate the exact heating load required to maintain comfortable indoor temperatures.

The Manual J method’s accuracy makes it invaluable for preventing the common pitfalls of underestimating or overestimating heating needs, thereby facilitating the selection of appropriately sized heating equipment.

B. Applying Load Factors for Different Building Zones

Different areas within a building may have varying heating requirements due to exposure to sunlight, prevailing winds, insulation levels, and usage patterns.

For instance, south-facing rooms might garner more natural heat during the day than north-facing ones, reducing the heating load needed in those areas. Similarly, spaces like basements or attics may require more heating due to their insulation characteristics and the likelihood of heat loss.

By segmenting a building into different zones and applying specific load factors to each, one can refine the overall heating load calculation, ensuring each area is adequately and efficiently heated.

C. Incorporating Equipment and Appliance Loads

In addition to the broader environmental and structural factors, the heat generated by household equipment and appliances can significantly affect a building’s overall heating load.

Devices that produce considerable amounts of heat, such as ovens, dryers, and even lighting systems, can contribute to the indoor climate.

While this may reduce the demand for the heating system in certain areas, it’s a factor that must be accurately assessed to avoid oversizing the furnace. Calculating the contribution of equipment and appliance loads to the overall heating requirement allows for a more precise and tailored approach to selecting a heating system.

How to Size a Furnace: Determining Furnace Size

Finding the right furnace size is paramount for achieving efficient heating without overspending on initial costs or ongoing energy bills.

This section outlines steps to select a furnace with the appropriate heating capacity, ensuring it matches the specific heating load requirements of the building and takes into account the furnace’s energy efficiency.

A. Selecting Appropriate Heating Capacity Based on Load Calculation

Once the heating load calculation is completed, the next step is selecting a furnace with the capacity to meet this demand. It’s essential to avoid the common pitfalls of choosing a furnace that is either too large or too small for the building.

A furnace with excessive capacity will cycle on and off more frequently, reducing its efficiency and lifespan, whereas a furnace that’s too small struggles to maintain comfortable temperatures, particularly on the coldest days.

Ideally, the furnace’s heating capacity should be as close as possible to the building’s calculated heating load without substantially exceeding it.

B. Matching Furnace Output to Heating Load Requirements

The furnace’s output, measured in BTUs (British Thermal Units), is a critical factor to consider when matching it to the building’s heating load.

This output should align closely with the heating load determined by the calculations discussed earlier. If the building’s heating load is 50,000 BTUs per hour, for instance, a furnace designed to deliver this amount provides the most efficient operation.

Some variability is acceptable to prevent inefficiency and unnecessary cost as long as the furnace’s output is not significantly higher than necessary.

C. Considering Furnace Efficiency Ratings

Furnace efficiency, indicated by the Annual Fuel Utilization Efficiency (AFUE) rating, plays a crucial role in selecting the right furnace size.

This rating measures the percentage of fuel converted into heat versus the amount lost through exhaust. Modern high-efficiency furnaces boast 90% to 98.5% AFUE ratings, meaning they convert almost all the fuel to useful heat.

A more efficient furnace can be smaller in capacity than a less efficient model while delivering the same amount of heat due to less energy being wasted. Therefore, when determining furnace size, one must consider both the heating load and the furnace’s efficiency rating to make an energy-efficient and cost-effective choice.

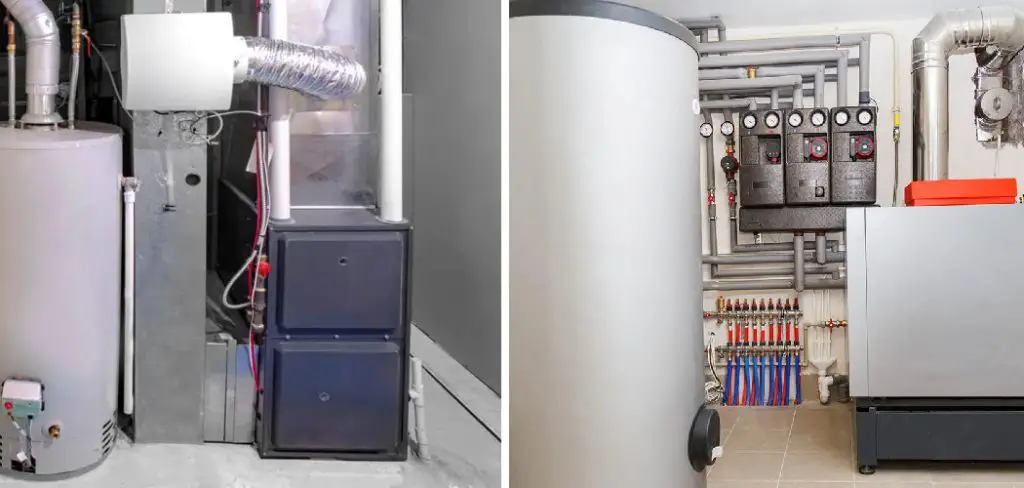

Sizing for Air Distribution

Proper duct sizing and airflow distribution are critical components in a building’s heating system to ensure efficient operation and comfort. This section examines the principles and strategies for achieving optimal ductwork design.

A. Ensuring Proper Duct Sizing and Airflow Distribution

The sizing of the ductwork in a heating system is essential for ensuring that heated air is distributed efficiently and comfortably throughout a building. Incorrect duct sizing can lead to poor air distribution, resulting in hot and cold spots, reduced heating system efficiency, and increased energy costs.

Proper duct sizing should be based on the heating load calculation results and the specific layout of the building, taking into account the length of duct runs and the number of bends. Airflow distribution also depends on the correct placement of vents and registers to circulate air effectively.

B. Matching Furnace Output to Duct System Capacity

To maximize heating efficiency, the furnace’s output must be matched not only to the building’s heating load but also to the duct system’s capacity to distribute air. A too powerful furnace for the ductwork can cause excessive air velocity, creating noise and reducing the system’s overall comfort and efficiency.

Conversely, a furnace with an output that is too low for the ductwork may not provide sufficient airflow to heat the space effectively. It is crucial to ensure that the duct system is designed to handle the furnace’s optimal output for balanced heating.

C. Avoiding Oversizing or Undersizing Ductwork

Just as with the furnace itself, the ductwork must neither be oversized nor undersized. Oversized ductwork can result in low air velocity, causing poor air distribution and stratification and leading to discomfort.

Meanwhile, undersized ductwork can restrict airflow, increasing static pressure, which reduces the efficiency of the heating system and can cause premature wear on furnace components.

Proper duct sizing involves calculating the optimum dimensions and layout for ducts based on the furnace’s capacity and the architectural features of the building. This ensures that heated air is delivered effectively to all areas without undue strain on the furnace or excessive energy consumption.

Considering Additional Factors

Efficient heating involves more than just matching furnace size to current building load requirements. Several additional factors must be considered to ensure long-term satisfaction and efficiency.

This section outlines the critical considerations of future expansion, occupancy patterns, heating preferences, and manufacturer recommendations that can significantly impact the selection and performance of a heating system.

A. Accounting for Future Expansion or Renovation

When planning for a heating system, it’s essential to consider any future expansions or renovations that might alter the heating load of the building. Anticipating changes in the building’s size, insulation, or usage can influence the choice of furnace size and design.

For instance, a building owner planning to add more space or increase insulation levels in the future may opt for a slightly larger furnace capacity or a modular heating system that can be adjusted to meet new demands.

This foresight prevents the need for a costly system replacement or retrofitting when the building’s heating requirements change.

B. Factoring in Occupancy Patterns and Heating Preferences

The number of occupants, their daily patterns, and specific heating preferences can also have a substantial impact on the heating system’s efficiency and suitability. Buildings with high occupancy or those used intermittently require different heating strategies.

For example, a home office or a gym within a residence may need different heating levels compared to the rest of the house. Advanced thermostat settings and zoned heating systems allow for the customization of heating patterns throughout the day and across different areas of a building, maximizing comfort while minimizing energy usage.

C. Consulting Manufacturer Recommendations

Lastly, the importance of adhering to manufacturer recommendations cannot be overstated. Manufacturers often provide valuable insights and guidelines on the optimal installation and operation of their products.

These recommendations can cover various aspects, from the minimum and maximum operating temperatures to the compatibility with different ductwork designs or auxiliary components.

Following these guidelines ensures that the furnace operates within its intended parameters, which can enhance efficiency, prolong the system’s lifespan, and preserve warranty coverage.

Consulting with a manufacturer or a certified HVAC professional can also provide clarity on the latest technologies and efficiency improvements available for new and existing heating systems.

Selecting Furnace Features

The selection of specific furnace features significantly influences a heating system’s efficiency, comfort level, and operational cost. This chapter explores the various furnace types, the advantages of variable-speed blowers and two-stage heating, and the importance of smart thermostat compatibility.

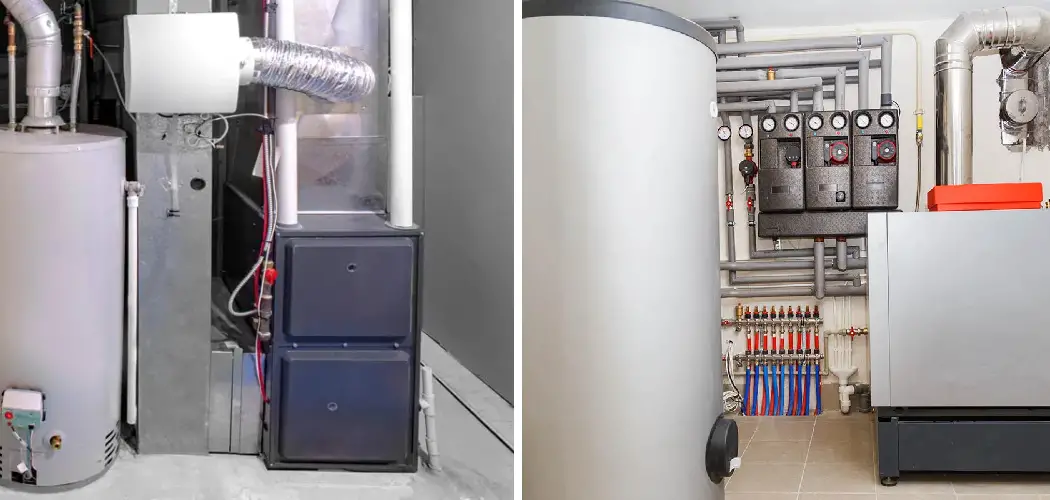

A. Exploring Different Furnace Types

Furnaces come in several types, each with unique characteristics and advantages suited to different needs and preferences.

The primary categories include single-stage, two-stage, and modulating furnaces. Single-stage furnaces operate at full capacity whenever they are running, providing a constant and powerful heat source.

Two-stage furnaces can operate at a lower capacity during milder conditions and ramp-up to full capacity in colder weather, balancing efficiency and comfort. Modulating furnaces offer the highest efficiency by continuously adjusting their flame and airflow to match the precise heating needs of the building, resulting in even temperatures and lower energy use.

B. Considering Variable-Speed Blowers and Two-Stage Heating

Variable-speed blowers and two-stage heating technologies enhance furnace efficiency and comfort. Variable-speed blowers adjust the speed of the air circulated through the ducts, providing a more consistent temperature throughout the building and reducing energy consumption.

Two-stage heating furnaces, with their ability to operate at low capacity under less demanding conditions, significantly improve energy efficiency while maintaining comfort by reducing temperature fluctuations. Both technologies contribute to quieter operation, longer lifespan of the heating system, and considerable energy savings over time.

C. Evaluating Smart Thermostat Compatibility

Smart thermostats represent a leap forward in heating system management, offering unparalleled control and efficiency.

These devices learn from your habits and adjust the heating accordingly, can be controlled remotely via smartphone apps, and provide detailed energy usage reports. When selecting a furnace, it’s crucial to ensure it is compatible with smart thermostats to fully leverage these benefits. Compatibility maximizes the potential for energy savings and enhances user convenience, making it a critical consideration in the furnace selection process.

Smart thermostat integration into a heating system enables advanced features such as geofencing, weather forecasting adjustments, and maintenance alerts, further optimizing heating performance and convenience.

Consulting with HVAC Professionals

A heating system’s successful selection and installation are greatly enhanced by consulting with HVAC professionals. Their expertise ensures that you choose the most efficient and suitable system for your specific needs.

This section explores the steps and benefits of engaging with qualified heating contractors, obtaining multiple quotes, and addressing any questions or concerns you may have.

A. Seeking Input from Qualified Heating Contractors

Engaging with qualified heating contractors is the first step toward ensuring the efficiency and effectiveness of your heating system.

These professionals can assess the specific needs of your building, taking into account its size, insulation, occupancy, and personal preferences. They provide invaluable advice on the type of heating system that best matches your requirements, considering the latest technologies and energy efficiency standards.

A qualified contractor will also identify any potential challenges in your current setup and recommend the best course of action, ensuring a smooth and efficient installation process.

B. Obtaining Multiple Quotes and Comparing Recommendations

It is prudent to obtain quotes from several contractors to ensure you are getting the best value and service.

Each contractor may offer different solutions, brands, and prices. Comparing these quotes allows you to evaluate the range of options available and make an informed decision based on cost, efficiency, and the installer’s reputation.

Furthermore, discussing these quotes with the contractors can provide deeper insights into each proposal’s merits and drawbacks, helping you to understand the long-term benefits and potential savings associated with each option.

C. Addressing Any Questions or Concerns

Throughout the consultation process, it is vital to address any questions or concerns you may have with the HVAC professionals.

Whether it’s about the type of furnace, the installation process, maintenance requirements, or warranty coverage, no question is too minor. Clear communication ensures that your needs and expectations are met and helps establish a transparent and trustful relationship with your contractor.

This open dialogue also enables you to understand the specifics of the proposed heating system, how it operates, and what maintenance it will require over time, ensuring you are comfortable and satisfied with your choice.

Conclusion

The process of determining how to size a furnace is critical in achieving a balance between efficiency, comfort, and operational costs.

This involves a thorough assessment of the building’s square footage, insulation quality, climate, and other factors that influence heating requirements. Correct furnace sizing ensures that the heating system operates at optimal efficiency without under or over-performing.

Accuracy in the furnace sizing process cannot be overstated. An accurately sized furnace not only enhances the comfort of occupants by maintaining consistent temperatures but also operates more efficiently.

This translates to lower energy bills and reduced environmental impact, showcasing the direct benefits of prioritizing precision in heating system selection.

Ultimately, the goal of understanding how to size a furnace correctly is to ensure maximum comfort for building occupants while minimizing energy consumption. A properly sized furnace adapts to the specific heating needs of a space, avoiding the pitfalls of short cycling or continual operation.

This guarantees a comfortable living or working environment and substantial energy savings over the system’s lifespan.