Are you frustrated with your boiler constantly turning on and off? This common issue, known as boiler short cycling, wastes energy and can lead to wear and tear on your heating system.

How to stop boiler short cycling is a common issue that can lead to inefficiencies in heating systems, increased energy costs, and unnecessary wear on the boiler. It occurs when a boiler turns on and off frequently in a short period, often failing to reach the desired temperature or satisfy the heating demand.

Understanding the root causes of this problem is essential for homeowners and facility managers alike. This guide will explore various strategies to effectively stop boiler short cycling, ensuring your heating system operates smoothly and efficiently.

Addressing this issue can enhance comfort levels, reduce fuel consumption, and prolong the lifespan of your boiler.

What are the Common Causes of Boiler Short Cycling?

Before diving into solutions for stopping boiler short cycling, let’s first understand its common causes:

- Oversized Boiler: If it is too large for your heating needs, it may frequently turn on and off as it quickly reaches the desired temperature.

- Faulty Thermostat: A malfunctioning thermostat may send incorrect signals to the boiler, causing it to cycle intermittently.

- Dirty Heat Exchanger: A buildup of dirt and debris on the heat exchanger can restrict airflow and lead to overheating, resulting in frequent cycling.

- Limescale Buildup: In areas with hard water, limescale can accumulate in the boiler’s pipes and components, hindering its efficiency and causing short cycling.

- Low Water Pressure: Low water pressure can cause a boiler to shut off as a safety precaution, leading to frequent cycling when trying to reach the desired temperature.

These are just a few common causes of boiler short cycling, and it’s important to address them promptly to prevent further issues and potential damage to your heating system.

What Will You Need?

To effectively stop boiler short cycling, you may need the following tools and materials:

- Screwdriver: This is used to check and adjust thermostat settings.

- Cleaning Supplies: To remove dirt and debris from the heat exchanger.

- Descaler Solution: In case of limescale buildup in the boiler.

- Water Pressure Gauge: To check and adjust water pressure.

Once you have these items, follow the steps below to stop the boiler short cycling:

10 Easy Steps on How to Stop Boiler Short Cycling

Step 1: Assess Boiler Size

The first step to effectively stopping boiler short cycling is to assess whether your boiler is appropriately sized for your heating needs. An oversized boiler can heat your home too quickly, leading to frequent shut-offs once the desired temperature is reached.

Ideally, your boiler should be sized based on factors such as the size of your home, insulation levels, and specific heating demands. To find the right boiler size, consider having a professional conduct a heat loss calculation, which will consider all relevant variables.

This assessment will help ensure that your heating system operates efficiently, minimizes short cycling, and maximizes comfort while reducing energy consumption. If you discover that your boiler is too large, consult a heating technician about options for replacement or adjustments to fit your requirements better.

Step 2: Check the Thermostat

Begin by inspecting your thermostat for any signs of malfunction. Ensure it is accurately calibrated and placed away from heat sources or drafts that could affect its readings.

If it’s an older model, consider replacing it with a modern, programmable thermostat that can provide more accurate temperature control. An improperly functioning thermostat can send erroneous signals to the boiler, causing it to cycle on and off excessively.

Step 3: Clean the Heat Exchanger

Cleaning the heat exchanger is a crucial step in addressing boiler short cycling. Over time, dirt, debris, and mineral deposits can accumulate on the heat exchanger’s surface, leading to impaired heat transfer and overheating. To begin, turn off the boiler and discharge the water to ensure safety.

Using a vacuum or brush, carefully remove any visible dirt and sediment. For more thorough cleaning, a commercial cleaning solution designed explicitly for boilers can be used to break down and remove more stubborn deposits. Following the manufacturer’s instructions when applying any cleaning products is essential and allowing adequate drying time before reassembling the components.

Step 4: Descale the Boiler

In areas with hard water, limescale buildup can significantly affect the efficiency of your boiler, leading to short cycling. To descale your boiler, start by turning off the power and water supply to the unit. Drain the boiler to ensure it is empty and safe to work on. Prepare a descaling solution according to the manufacturer’s instructions, which may include specific chemicals designed to dissolve limescale.

Pour the solution into the boiler and allow it to sit for the recommended time, allowing the chemicals to break down the limescale deposits. After sufficient time, flush the system with clean water to remove all traces of the descaler and the dislodged limescale. Ensure that you fill and drain the boiler several times to guarantee that all residues are eliminated.

Step 5: Check and Adjust Water Pressure

Low water pressure can contribute to boiler short cycling, as many systems will shut off if pressure drops below a specified threshold. Start by using a water pressure gauge to check the current pressure in your boiler. The ideal range typically falls between 1 to 1.5 bar when the boiler is cold and can rise to approximately 2.5 bar when operating.

You must add water to the system if your reading is below this range. Locate the filling loop, usually connected to the main water supply, and open it gently to allow water to fill the boiler until the correct pressure is reached. Keep a close eye on the pressure reading while filling to avoid over-pressurization. Once the pressure is correct, close the filling loop and remove the gauge.

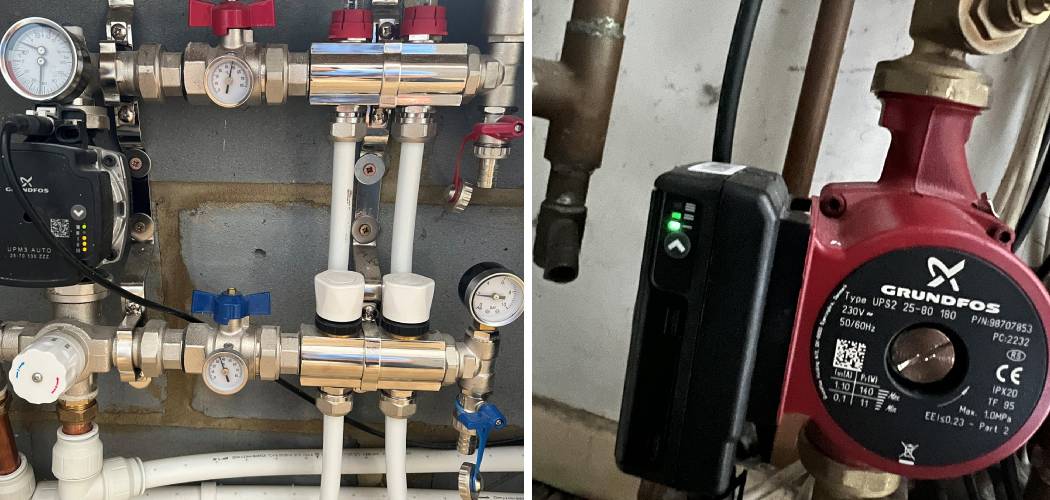

Step 6: Inspect the Boiler’s Components

Routine inspection of your boiler’s components is vital in preventing short cycling. Review all visible parts, including the pump, valves, and expansion tank. Look for any signs of corrosion, leaks, or damage that could impair performance. Pay particular attention to the sight glass and pressure relief valve, ensuring they function correctly.

Consider consulting a professional for repairs or replacements if you notice any worn or damaged components. Additionally, check the venting system for blockages or restrictions, as these can hinder exhaust flow and affect the boiler’s efficiency, leading to cycling issues.

Step 7: Consider System Controls

Modern heating systems often have advanced controls or intelligent technology to improve efficiencies and reduce short cycling. If your boiler is compatible, consider upgrading to a weather-compensating control system, which adjusts the boiler’s output based on the outside temperature. This can help maintain an even temperature throughout your home and reduce the need for excessive cycling.

Additionally, installing a buffer tank (or thermal storage tank) can help regulate the boiler’s workload. The tank allows the boiler to run optimally without frequent shutdowns by storing hot water during peak operation periods. If your system does not currently have these intelligent features, consulting a heating professional may provide options for integrating newer technology into your existing setup.

Step 8: Schedule Regular Maintenance

Investing in regular maintenance for your boiler is one of the best ways to prevent short cycling and ensure overall efficiency. Schedule annual inspections by a qualified technician who can thoroughly check all components, clean the system, and address any emerging issues. During these maintenance visits, the technician can perform critical tests, such as combustion analysis, to ensure the system operates safely and efficiently.

This proactive approach not only helps prevent short cycling but also extends the lifespan of your boiler, saving you money on repairs and energy costs over time. Create a maintenance log to track inspections and any work done to keep your boiler in top condition, ensuring that issues are addressed promptly.

Step 9: Monitor System Performance

After implementing the previous steps, take note of your boiler’s performance over the following weeks. Keep track of any changes in heating efficiency, temperature consistency, and how frequently the boiler turns on and off. If you continue to experience short cycling despite your efforts, it may indicate deeper underlying issues that require professional intervention.

Regularly monitoring your system helps detect potential problems early and allows you to gauge the effectiveness of the implemented changes. Maintain a record of your observations to discuss with your technician, which can provide additional insights during maintenance visits.

Step 10: Educate Yourself on Boiler Use

Finally, a crucial step in stopping boiler short cycling is understanding how to use your system effectively. Read the user manual thoroughly to become familiar with the boiler’s functions, settings, and operational characteristics.

Familiarize yourself with the best practices for adjusting thermostats and setting timers and understand how external factors (such as changes in weather) can affect heating demands. By being an informed user, you can operate your boiler more efficiently and advocate for any changes or repairs needed to optimize its performance.

By following these steps, you can effectively combat boiler short cycling and ensure optimal heating system performance.

Conclusion

In conclusion, how to stop boiler short cycling requires a comprehensive approach that includes regular maintenance, proper monitoring, and an understanding of your system’s operation.

By routinely checking water pressure, inspecting components, considering intelligent system controls, and scheduling consistent professional maintenance, you can drastically reduce the likelihood of short cycling.

Additionally, keeping informed about usage practices and potential issues will empower you to manage your heating system more efficiently. Implementing these strategies ensures your boiler’s longevity and contributes to a more comfortable and cost-effective home heating experience.

By being proactive, you can maintain optimal performance and enjoy the benefits of a well-functioning heating system.