A furnace blower motor is a crucial component of your home heating system. It is responsible for circulating hot air throughout your house, keeping you warm and comfortable during the cold winter months. However, like any mechanical device, the furnace blower motor can malfunction or go bad over time.

It’s important to be able to recognize the signs of a bad furnace blower motor so that you can address the issue promptly and avoid potential safety hazards or expensive repairs. In this guide on how to tell if a furnace blower motor is bad, we will discuss how to tell if your furnace blower motor is bad and what you should do about it.

Why Does a Furnace Blower Motor Go Bad?

Before we dive into the signs of a bad furnace blower motor, it’s important to understand why it may go bad in the first place. The most common reasons for a faulty furnace blower motor include:

Age:

Like any mechanical component, the furnace blower motor will eventually wear out over time. Most experts recommend replacing a furnace blower motor every 10-15 years.

Lack of Maintenance:

Regular maintenance of your heating system is crucial to ensuring its longevity and efficiency. Neglecting to clean or lubricate the furnace blower motor can lead to premature wear and tear, causing it to go bad sooner.

Power Surge:

A sudden spike in electricity can damage electrical components, including the furnace blower motor. This can happen during a lightning storm or when there are power outages.

Overheating:

If the furnace blower motor is constantly running at high speeds due to clogged air filters or blocked vents, it may overheat and burn out.

Needed Materials

To determine if your furnace blower motor is bad, you will need the following materials:

Screwdriver:

To access the furnace blower motor, you will need to remove the cover panel using a screwdriver.

Multimeter:

A multimeter is an essential tool for testing electrical components and determining if they are functioning properly.

Replacement Motor:

If your furnace blower motor is indeed bad, you will need to purchase a new one to replace it.

8 Simple Step-by-step Guidelines on How to Tell if a Furnace Blower Motor is Bad

Step 1: Turn off the Power

Before performing any checks or maintenance on your furnace blower motor, it is essential to ensure your safety by turning off the power to the unit. Locate the power switch for your furnace, typically found on the side of the furnace or in your electrical panel, and switch it off. This prevents any accidental start-ups while you are inspecting or working on the blower motor.

Additionally, it is advisable to disconnect the furnace from the power source by unplugging it or switching off the circuit breaker dedicated to the heating system. Always take this precaution to avoid electric shocks or injuries.

Step 2: Remove the Cover Panel

Once you have turned off the power to your furnace, the next step is to remove the cover panel to access the furnace blower motor. Use your screwdriver to carefully unscrew the fasteners, securing the panel in place. Set the screws aside in a safe location to prevent losing them. Gently lift or slide off the cover panel, depending on your furnace model.

Be cautious while handling the panel, as it may have sharp edges. With the cover panel removed, you should have clear access to the blower motor and be prepared to examine its condition further.

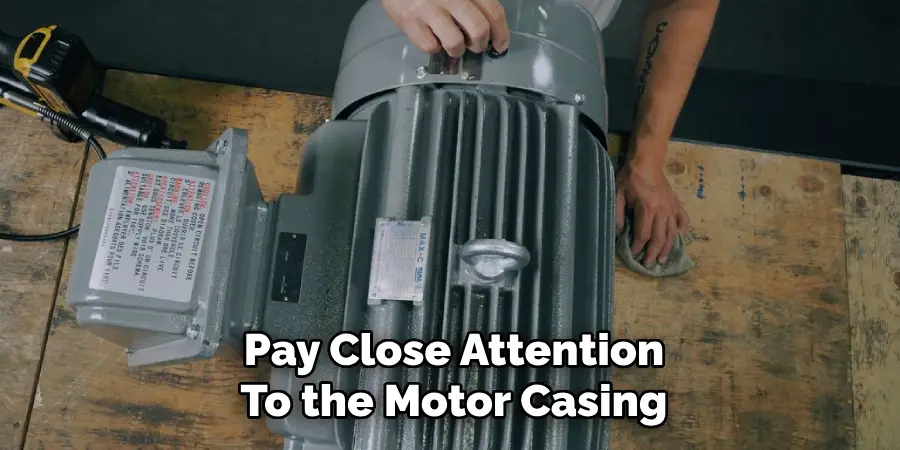

Step 3: Inspect for Physical Damage

After removing the cover panel, carefully inspect the furnace blower motor for any visible signs of physical damage. Look for cracks, burns, or frayed wires that could indicate wear and tear. Pay close attention to the motor casing and connections; any deformation or discoloration could suggest overheating or electrical issues.

Additionally, check for debris or dust buildup around the motor that might hinder its performance. If you notice any significant damage, it may be necessary to replace the blower motor to ensure safe and effective operation of your heating system.

Step 4: Test the Capacitor

The capacitor is a component of the furnace blower motor that helps start and regulate its speed. A faulty capacitor can cause the blower motor to malfunction or fail altogether. To test the capacitor, use your multimeter set to capacitance mode and touch the probes to each end of the capacitor’s terminals. If you get a reading close to zero, it means that the capacitor is defective and needs replacement.

The specific value of the reading will vary depending on your furnace model, so consult your manufacturer’s manual for the correct range. If you are unsure how to test and replace a capacitor, it is best to call a professional technician for assistance.

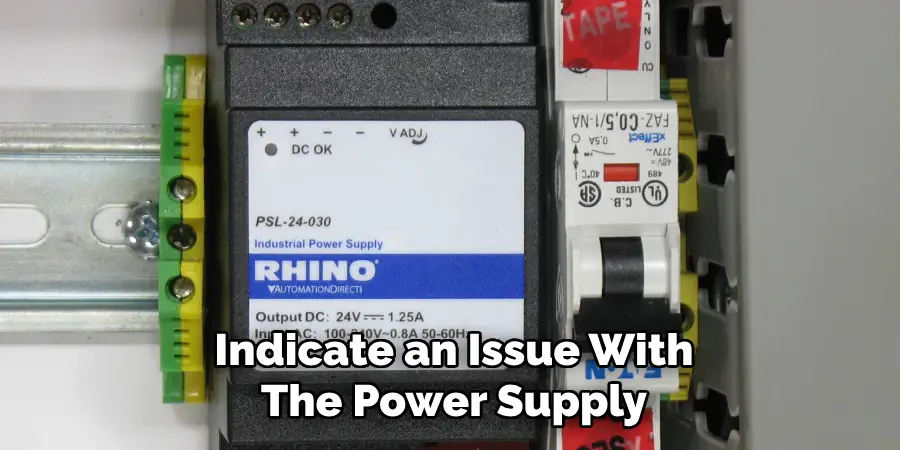

Step 5: Check for Power Supply

Once you have inspected the capacitor, the next step is to verify that the furnace blower motor is receiving power. To do this, set your multimeter to the voltage setting and carefully check the voltage at the motor’s electrical connections. Ensure the power is restored to the furnace before doing this. A properly functioning blower motor should receive the appropriate voltage as specified in your furnace manual, typically between 120-240 volts.

If there is no voltage present or the reading is below the required range, it may indicate an issue with the power supply, such as a blown fuse, tripped circuit breaker, or faulty wiring. If you identify any problems with the power supply, consult a qualified electrician to rectify the situation before further troubleshooting the blower motor.

Step 6: Inspect the Fan Belt

If your furnace uses a belt-driven blower motor, it is essential to check the fan belt’s condition. Over time, the belt can become loose or damaged, causing issues with the blower motor’s performance. To inspect the fan belt, turn off the power supply and locate it on the side of the motor.

Check for signs of wear and tear, such as cracks or fraying along its surface. If you notice any damage, replace the fan belt following your manufacturer’s instructions.

Step 7: Test for Continuity

To determine if the furnace blower motor is functioning properly, you will need to test for continuity using your multimeter. First, ensure that the power is off to the furnace to prevent any electrical hazards. Then, disconnect the wires connected to the motor terminals. Set your multimeter to the continuity setting, and touch the probes to the motor terminals.

A continuous beep or a reading close to zero indicates that the motor has continuity and is likely functioning correctly. If there is no sound or an infinite reading, this suggests a break in the winding, indicating that the motor is likely defective and requires replacement.

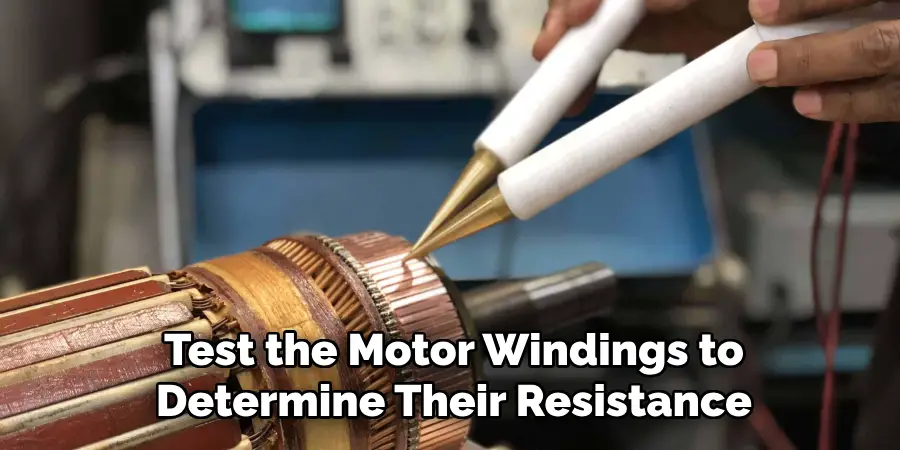

Step 8: Test the Motor Windings

Continuing with your multimeter, you can also test the motor windings to determine their resistance. This step is especially useful if you suspect an issue with the winding since it can cause the blower motor to overheat and fail. To test the windings, set your multimeter to ohms mode and touch one probe to a terminal and the other probe to a grounded metal surface.

You should get a reading within the range specified in your furnace manual for each winding. If any of the readings are outside this range or show an infinite reading, it could indicate a problem with that specific winding.

Additional Tips for Maintaining Your Furnace Blower Motor

Regularly inspecting and cleaning your furnace blower motor can help prevent issues and extend its lifespan. Here are a few additional tips for maintaining your furnace blower motor:

- Keep the area around the furnace clean and free of debris to prevent clogs in the motor.

- Clean or replace air filters regularly to improve airflow and reduce strain on the blower motor.

- Lubricate any moving parts according to your manufacturer’s recommendations to keep them functioning smoothly.

- Schedule annual maintenance with a professional technician to ensure all components, including the blower motor, are in good working condition.

- If you notice any unusual noises or performance issues with your furnace, do not hesitate to call a professional for assistance. Delaying repairs can lead to further damage and potentially costly replacements.

By following these steps and tips on how to tell if a furnace blower motor is bad, you can ensure that your furnace blower motor stays in top condition, providing efficient heating for your home. Remember to always prioritize safety when inspecting and repairing your furnace, and do not hesitate to seek professional help if needed.

Conclusion

In conclusion, understanding how to diagnose issues with your furnace blower motor is vital for maintaining an efficiently heating system in your home. By following the outlined steps on how to tell if a furnace blower motor is badfrom inspecting the motor for damage to testing components such as the capacitor and the windings, you can effectively troubleshoot potential problems.

Regular maintenance, such as cleaning, lubricating, and replacing worn parts, will not only enhance the performance of your furnace but also extend its lifespan. Always remember to prioritize safety during inspections and repairs, and don’t hesitate to seek professional assistance when necessary. With proactive care, you can ensure your furnace blower motor operates seamlessly, keeping your home warm and comfortable throughout the colder months.