In the heart of cold weather, the furnace becomes an essential ally in maintaining home comfort, transforming chill interiors into warm, welcoming spaces. Central to its operation is the furnace ignitor, a critical component that jump-starts the heating process.

However, much like any other part, ignitors can fail, casting a cold shadow over your cozy home environment. Knowing how to tell if a furnace ignitor is bad is crucial for timely troubleshooting and replacement, ensuring your living spaces remain pleasantly warm throughout the frosty months.

This guide explores the unmistakable signs of a failing ignitor and lays down the groundwork for addressing this common furnace issue, providing a roadmap for maintaining an efficient and reliable heating system.

The Role of the Furnace Ignitor

The furnace ignitor plays a pivotal role in the heating cycle, acting as the initial spark that lights the furnace’s burner, thus beginning the process of warming the air that circulates throughout your home. This component replaces the traditional pilot light, offering a more efficient and reliable means of ignition.

Two types of ignitors are commonly found in modern furnaces: the glow plug and the hot surface igniter (HSI). The glow plug operates similarly to those found in diesel engines, heating up to ignite the gas, while the HSI, made of materials like silicon carbide or silicon nitride, heats up to a high temperature to light the burner. Despite their efficiency, furnace ignitors are not designed to last forever.

Their average lifespan typically ranges between 3 to 7 years, depending on the ignitor type, furnace usage, and the frequency of cycling on and off. Knowing this, it’s essential to monitor their condition and understand the importance of timely replacement to ensure uninterrupted heating performance.

How to Tell if A Furnace Ignitor Is Bad: Signs of a Failing Furnace Ignitor

No Heat or Cold Air Only

One of the most straightforward signs of a failing furnace ignitor is the absence of heat or the emergence of cold air from the vents, contrary to what is expected when the thermostat is cranked up. This phenomenon occurs due to the ignitor’s inability to ignite the gas burner, a critical step in the heating process. Under normal circumstances, adjusting the thermostat above room temperature sends a signal to the furnace to start the heating cycle.

This cycle begins with the ignitor heating up to a point where it can ignite the gas released into the burner, thereby generating heat. However, if the ignitor is malfunctioning or has failed completely, it won’t reach the necessary temperature to ignite the gas. As a result, the furnace’s blower might still circulate air through the vents, but without the initial ignition, this air remains unheated.

Homeowners may notice that despite setting the thermostat to a higher temperature, the air flowing through the vents is notably cool, indicating that the furnace is not producing heat due to a potentially failed ignitor.

Visual Inspection of the Ignitor

A visual inspection of the furnace ignitor can offer valuable insights into its condition and help determine whether it may be the source of heating issues. Safety is paramount when conducting this type of inspection.

Before opening the furnace to access the ignitor, ensure the furnace is turned off and disconnected from its power source to avoid any risk of electric shock or injury. Wearing safety gloves and eye protection is also advisable to protect against sharp edges within the furnace interior.

During the inspection, look for obvious signs of wear or damage on the ignitor. Common indicators include cracks, significant discoloration, or apparent physical damage to the component. Such issues can prevent the ignitor from functioning correctly. Cracks or breaks in the ignitor are especially critical, as they directly affect the ability of the ignitor to heat up properly and ignite the gas.

Discoloration might suggest a history of overheating or irregular operation, potentially signifying nearing the end of life. Taking note of these signs during a visual inspection can help diagnose a bad furnace ignitor and guide the next steps in troubleshooting or replacement.

Importance of Professional Diagnosis

Consulting with a qualified HVAC technician for an accurate diagnosis of furnace issues, especially when it concerns the ignitor, cannot be overstated. While homeowners may attempt to diagnose problems themselves, the intricacies of furnace components and the potentially hazardous nature of electrical systems present significant risks to those unfamiliar with this type of work.

A professional technician brings expertise in identifying the signs of a failing furnace ignitor and a thorough understanding of the safety protocols required to perform repairs without causing injury or further damage to the system.

DIY attempts at furnace repair can inadvertently overlook the actual root cause of the problem, leading to a temporary fix at best or, at worst, exacerbating the issue. An experienced HVAC professional, however, can accurately diagnose the underlying issues, ensuring that the repair or replacement addresses the real problem, saving time and money in the long run.

The benefits of a professional diagnosis extend beyond identifying the problem. Qualified technicians can recommend the most efficient and cost-effective solution tailored to the specific situation, whether it be a simple repair or a complete component replacement.

Furthermore, professional repairs are performed with safety as a top priority, adhering to industry standards to ensure that the furnace operates reliably and safely post-repair.

That’s it! You’ve now learned how to tell if a furnace ignitor is bad and the importance of seeking professional help to diagnose and repair any furnace issues.

Remember to regularly monitor your furnace ignitor’s condition, as it is a vital component in keeping your home warm and comfortable during the colder months. Always consult with a qualified HVAC technician for safe and efficient repairs when in doubt. Stay warm! The end.

Basic Troubleshooting Steps (Before Calling a Technician)

Safety Reminder: Before attempting any troubleshooting steps, it’s imperative to ensure your safety and the safety of those around you. Always turn off the furnace’s power supply at the breaker box to avoid the risk of electric shock or injury. Confirm that the power is indeed off before proceeding with any inspection or maintenance tasks.

A. Check the Thermostat

A common issue that could prevent your furnace from igniting, even with a functional ignitor, is a malfunctioning thermostat. First, ensure that the thermostat is set to “heat” mode and that its temperature setting is above the current room temperature. This may seem basic, but it’s often overlooked.

A thermostat set in “cool” mode or at a temperature below room temperature will not signal your furnace to start the ignition process. If your furnace continues to malfunction despite these adjustments, the problem may lie elsewhere, but starting with the thermostat is a simple and often effective first step.

B. Check the Air Filter

Restricted airflow due to a clogged air filter is another common culprit behind furnace malfunctions, including issues with ignition. A dirty air filter can severely limit the amount of air circulating through your system, leading to overheating and potential damage.

Locate your furnace’s air filter—typically found in the return air duct or mounted on the furnace itself. Check if it appears dirty or clogged, and replace it if necessary. Regular air filter replacement or cleaning is crucial for maintaining optimal furnace performance and preventing ignition problems before they start.

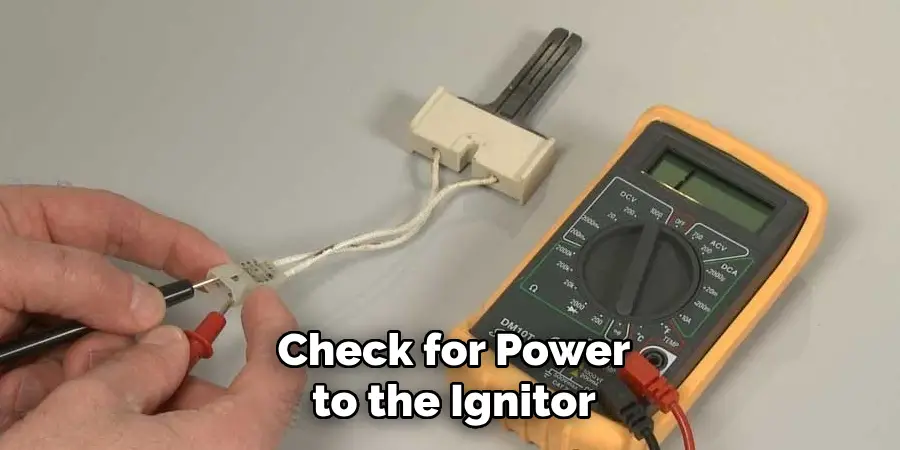

C. Check for Power to the Ignitor

Caution: Checking for power to the ignitor involves working with the furnace’s electrical system and requires a multimeter and some familiarity with electrical work. If you’re uncomfortable with this step, it’s best to consult with a professional.

To check for power to the ignitor, first, ensure that your furnace is off and you have safe access to its internal components. Locate the ignitor and its connector. Using a multimeter set to measure voltage, check the voltage at the ignitor connector by attaching the multimeter leads to the connector terminals.

The expected voltage reading should be within the specifications provided by the furnace manufacturer, typically around 120 volts for many residential furnaces.

A correct voltage reading indicates that the ignitor is receiving power. Suppose the reading is significantly lower or there is no voltage. In that case, this points to an issue with the power supply to the ignitor, which could be due to a variety of electrical malfunctions. In such cases, deeper electrical diagnostics are required, which are best carried out by a qualified technician.

Solutions for a Failing Ignitor

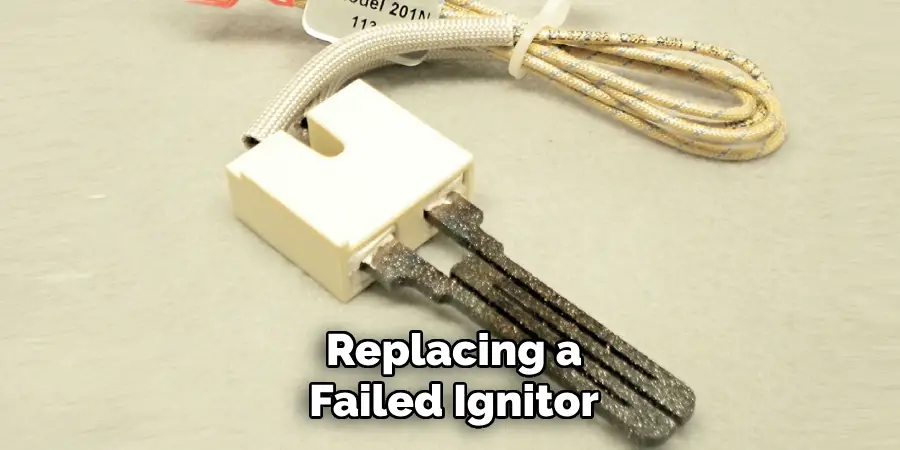

Replacing the Ignitor

When a furnace ignitor fails, the most effective course of action is often to replace the component. Replacing a failed ignitor can restore the functionality of your furnace, ensuring it can efficiently heat your home. The replacement process involves several crucial steps that must be carried out with care and precision.

First, it’s important to identify the exact type of ignitor used in your furnace, as using the correct replacement part is essential for proper operation. The ignitor type should be specified in your furnace’s manual or can be determined by consulting the manufacturer’s customer service.

Once the appropriate replacement ignitor is obtained, the power to the furnace should be turned off at the breaker to ensure safety during the replacement process.

The actual steps for replacing the ignitor typically involve accessing the furnace’s interior, carefully disconnecting the old ignitor, and installing the new one in its place. It’s paramount to handle the new ignitor gently, as they can be quite fragile. The wires should be connected exactly as they were on the old ignitor to avoid any misconfiguration.

Given the critical nature of the task and the importance of meticulously following the manufacturer’s instructions, working with gas appliances and electrical components poses inherent risks.

For homeowners who are not comfortable or experienced with this type of repair, or if there’s any uncertainty about the process, consulting a qualified HVAC technician for the replacement is strongly recommended.

A professional can ensure that the replacement is performed safely and correctly, mitigating the risk of further complications or hazards.

Addressing Underlying Issues

While replacing a failing ignitor can resolve the immediate problem, it’s important to consider that this failure could be symptomatic of a deeper, underlying issue within the furnace system. Factors such as insufficient airflow, electrical problems, or even a malfunctioning control board can lead to repeated ignitor failures over time.

Therefore, beyond merely replacing the ignitor, it’s crucial to have a comprehensive diagnostic evaluation performed by a professional HVAC technician.

A thorough examination can uncover any additional problems that may have contributed to the ignitor’s failure, ensuring that all root causes are addressed. This proactive approach not only helps prevent future issues but also contributes to your furnace’s overall reliability and efficiency.

Professional Repair and Maintenance

Benefits of Professional Repair

Hiring a qualified HVAC technician to diagnose and repair a failing ignitor brings many benefits beyond the immediate fix. Firstly, their expertise and extensive training in troubleshooting various furnace problems enable them to accurately identify the root cause of an issue, leading to more effective and long-lasting repairs.

This expertise is crucial for complex systems where an incorrect diagnosis can lead to unnecessary expenses or further damage. Secondly, safety is a significant concern when dealing with gas furnaces and electrical components.

Professionals are equipped with the necessary tools and knowledge to conduct repairs safely, minimizing the risk of accidents or exposure to hazardous conditions. Additionally, a professional repair often comes with a guarantee or warranty, providing homeowners with peace of mind and protection against recurrent issues.

Lastly, by addressing the problem correctly the first time, qualified technicians help prevent further damage to the system, which can save homeowners significant amounts of money in the long run. Their ability to identify and rectify potential issues before they escalate into major problems is an invaluable asset in maintaining a furnace’s longevity and efficiency.

Preventative Maintenance

Preventative maintenance is pivotal in ensuring the longevity and reliability of your furnace, particularly in preventing ignitor problems and ensuring optimal performance throughout the colder months.

An appropriately scheduled maintenance plan typically includes a comprehensive inspection and cleaning of the furnace’s components, such as the air filter, heat exchanger, and the ignitor itself. This process helps in identifying signs of wear and tear early, allowing for timely repairs or replacements before issues become severe.

Additionally, a technician will check for proper airflow and adjust the furnace settings to ensure it operates at peak efficiency. Regular maintenance also includes checking the furnace’s electrical connections and ensuring that the system’s control board and other electronic components are functioning correctly.

Beyond extending the life of the furnace and preventing unexpected failures, regular maintenance supports optimal energy efficiency, which can lead to significant savings on energy bills. Homeowners who invest in a routine maintenance schedule enjoy not only peace of mind but also the benefits of a well-performing heating system that remains reliable and efficient year after year.

Conclusion

In summary, addressing a failing furnace ignitor involves a series of strategic troubleshooting steps, beginning with the identification of the correct ignitor type, followed by a safe replacement process. It’s essential to emphasize how critical it is to follow manufacturer guidelines closely and handle replacement parts with care, particularly given the fragile nature of ignitors.

Beyond the immediate fix, it’s crucial to consider potential underlying issues contributing to the ignitor’s failure, which underscores the importance of conducting a comprehensive diagnostic evaluation.

Safety cannot be overstated; if there’s any hesitation or uncertainty about the process, seeking the assistance of a qualified HVAC technician is strongly advised. Through their expertise, these professionals ensure the repair is executed safely and contribute to the furnace’s long-term efficiency and reliability.

For homeowners wondering how to tell if a furnace ignitor is bad, symptoms can include the furnace not igniting or heating intermittently. However, because these signs could also indicate other issues, consulting professional help is recommended for an accurate diagnosis.

Additional furnace maintenance and troubleshooting resources are available through reputable HVAC companies’ online guides. These resources can provide invaluable information on recognizing signs of wear, performing routine checks, and understanding when to call in a professional.

Prioritizing regular maintenance and being proactive about seeking professional advice can significantly enhance the furnace’s lifespan while ensuring a warm and safe environment at home.