Recognizing the signs of a faulty pressure switch is crucial for maintaining the efficiency and safety of various appliances, from HVAC systems to water pumps. A pressure switch serves as a vital component in these devices, responsible for monitoring and regulating the pressure levels within a system.

When a pressure switch malfunctions, it can lead to a range of issues, including improper operation, reduced performance, and even potential safety hazards. In this guide, we delve into how to tell if pressure switch is bad, empowering homeowners and technicians alike to diagnose and address these issues effectively.

By understanding the symptoms of a bad pressure switch, individuals can take proactive steps to troubleshoot, repair, or replace the faulty component, ensuring the continued functionality and reliability of their appliances and systems.

Importance of Detecting a Faulty Pressure Switch Early

Detecting a faulty pressure switch early is of paramount importance for several reasons. Firstly, it can prevent more severe damage to the appliance or system it controls, saving homeowners and businesses considerable repair costs. Early detection ensures that systems operate within their intended parameters, promoting longevity and reliability.

Furthermore, addressing problems with the pressure switch promptly can significantly enhance the safety of the environment. A malfunctioning pressure switch may fail to regulate pressure adequately, posing a risk of leaks, bursts, or even fires, depending on the system involved.

Timely intervention not only mitigates these risks but also contributes to the efficient operation of appliances, leading to energy savings and consistent performance.

Recognizing the early signs of a failing pressure switch thus stands as a critical maintenance skill that can foster safer, more sustainable, and cost-effective management of various systems and devices.

Understanding Pressure Switches

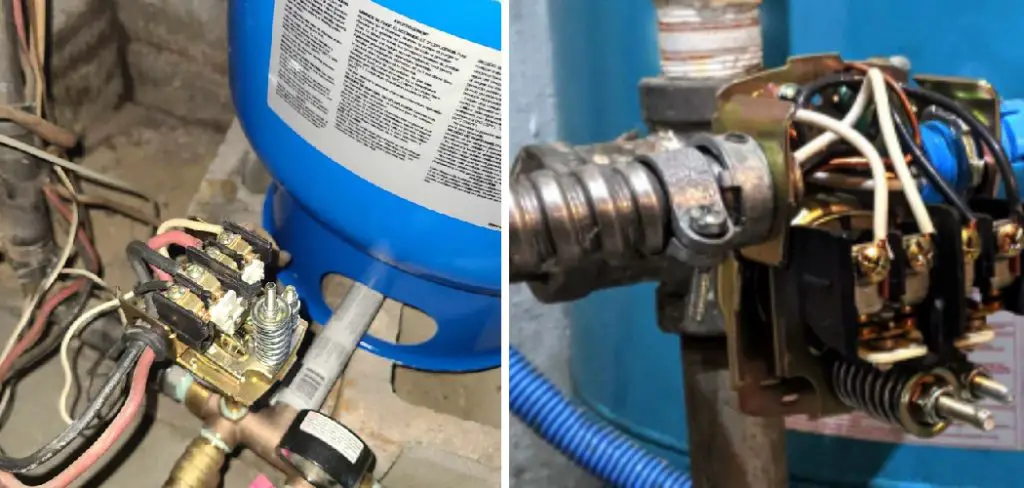

At its core, a pressure switch is a safety and control device found in a myriad of applications, from residential HVAC systems to industrial machinery. It is designed to automatically sense changes in pressure within a system and actuate either an alarm, a control signal, or directly control the operation of the system to maintain the pressure within a desired range.

Essentially, pressure switches operate based on the principle of setpoints. A setpoint is predetermined pressure level at which the switch will either open or close the electrical circuit it controls.

This action, in turn, either initiates or halts the operation of a device, such as a pump or a compressor, ensuring the system maintains its intended pressure level. This critical function helps prevent issues such as over-pressurization or under-pressurization, both of which can lead to equipment failure, safety hazards, and inefficiency in energy use.

Understanding how pressure switches work, the roles they play in various systems, and their operating principles is fundamental to diagnosing issues related to these components.

What Is a Pressure Switch?

A pressure switch is a critical safety and control instrument utilized across an extensive array of appliances and systems, tailored to automatically monitor and regulate pressure levels.

Its primary function is to ensure that the pressure within a system stays within safe and efficient boundaries by activating or deactivating the equipment based on the existing pressure.

Constructed with a sensor that detects pressure changes, the switch can trigger an electrical response—be it opening or closing a circuit—when the pressure crosses a preset threshold.

This automatic response is integral to maintaining optimal operational conditions, preventing damage due to excessive pressure, and ensuring safety standards are met. Pressure switches are indispensable in environments where precise pressure management is essential, demonstrating their versatility from household appliances to industrial machinery.

Function and Role in Various Systems

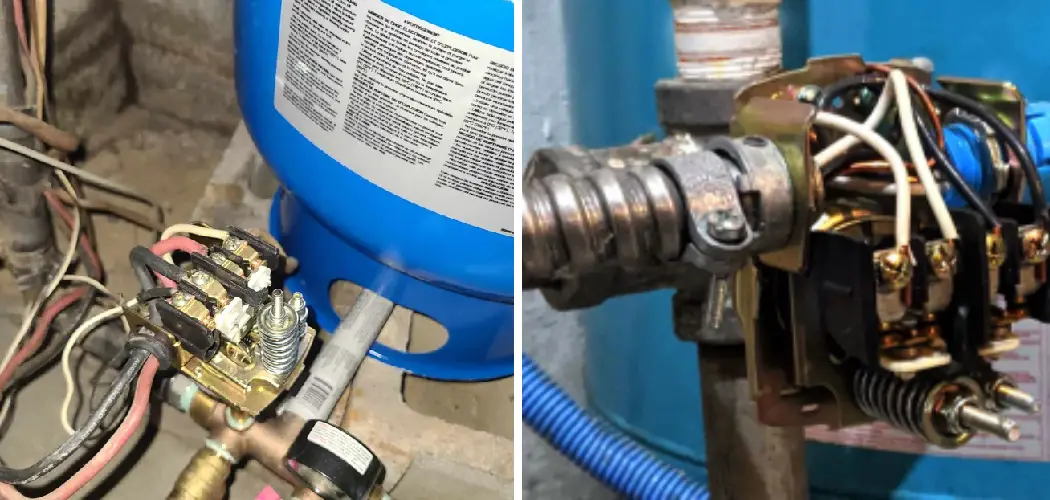

Pressure switches play a pivotal role across a wide spectrum of applications, serving as a linchpin for ensuring the efficiency, reliability, and safety of various systems. In residential contexts, they are commonly found in water pumps and HVAC systems.

In a water pump system, the pressure switch ensures that the water pressure remains stable throughout the home, preventing situations of over-pressurization that can lead to pipe damage or under-pressurization that can cause inadequate water flow.

Similarly, in HVAC systems, pressure switches contribute to maintaining optimal operating pressures, safeguarding against conditions that could lead to compressor failure or inefficient heating and cooling.

In industrial settings, pressure switches assume critical functionalities in machinery and equipment ranging from pneumatic and hydraulic systems to boilers and air compressors.

Their ability to detect and respond to pressure changes makes them invaluable for preventing equipment failure due to over- or under-pressurization, thereby averting potential safety hazards and costly downtimes.

Furthermore, pressure switches are instrumental in process control environments, where maintaining precise pressure levels is necessary for the quality and consistency of the products being manufactured.

The versatility of pressure switches is also evident in the automotive industry and aerospace applications, where they are used to monitor oil and fuel pressures, ensuring the reliable operation of engines and hydraulic systems.

This wide-ranging applicability underscores the essential function and role of pressure switches in not only maintaining operational efficiency and safety but also in extending the lifespan of systems and appliances by preventing pressure-related failures.

Common Types of Pressure Switches

Pressure switches come in various types, each tailored to specific applications and operational needs. Here’s an overview of the most common types:

- Electromechanical Pressure Switches: These devices feature a physical process, such as the movement of a diaphragm or a piston, to actuate an electrical switch based on a preset pressure level. They are known for their reliability and straightforward design, making them suitable for a wide range of industrial and residential applications.

- Digital Pressure Switches: Offering precision and programmability, digital pressure switches use electronic sensors to measure pressure and digital circuits to process the data. These switches can provide detailed feedback, including real-time pressure readings, through digital displays and are easily integrated into modern control systems.

- Differential Pressure Switches: Specifically designed to actuate based on the difference in pressure between two points, differential pressure switches are essential in applications where maintaining a specific pressure difference is critical, such as in filter systems, where they monitor the pressure drop across a filter to indicate when cleaning or replacement is necessary.

- Vacuum Pressure Switches: Operating on the principle similar to that of other pressure switches, vacuum pressure switches are specifically designed to respond to changes in vacuum conditions rather than liquid or gas pressure. These switches are commonly used in vacuum systems and equipment to ensure optimal vacuum levels are maintained.

Each type of pressure switch has its unique advantages and specific use cases, making it important to select the right type based on the operational requirements of the system or application it will be used in.

10 Methods How to Tell if Pressure Switch Is Bad

01.Inconsistent Functionality:

One of the primary signs of a faulty pressure switch is inconsistent functionality. If the switch fails to activate or deactivate reliably in response to changes in pressure, it could indicate a problem.

For example, if a water pump fails to turn on when the pressure drops below a certain level or doesn’t shut off when the pressure reaches the desired threshold, the pressure switch may be at fault.

02.Irregular Cycling:

A malfunctioning pressure switch may cause the appliance or system to cycle irregularly. Instead of cycling on and off smoothly in response to changes in pressure, the switch may cause rapid cycling, where the appliance turns on and off frequently, or it may fail to cycle at all, remaining stuck in either the on or off position.

03.Low Pressure or Flow:

If a pressure switch is failing to detect changes in pressure accurately, it may result in reduced pressure or flow in the system it controls. For example, a malfunctioning pressure switch in a water pump system may fail to activate the pump when water pressure drops, leading to inadequate water flow from faucets or fixtures.

04.High Energy Consumption:

A faulty pressure switch can also contribute to increased energy consumption. If the switch fails to regulate the operation of the appliance or system efficiently, it may cause the equipment to run continuously or cycle more frequently than necessary, resulting in higher energy bills.

05.Visible Damage or Corrosion:

Inspect the pressure switch for any visible signs of damage, such as cracks, breaks, or corrosion. Physical damage or corrosion can compromise the integrity of the switch, leading to malfunctioning or erratic behavior.

Additionally, check the electrical connections and terminals for signs of corrosion or loose connections, as these issues can also affect the performance of the pressure switch.

06.Audible Clicking or Humming:

A malfunctioning pressure switch may produce unusual sounds, such as clicking, humming, or buzzing noises.

These sounds can indicate that the switch is struggling to function properly or that it is experiencing internal mechanical issues. If you notice any unusual noises coming from the pressure switch or the appliance it controls, it may be a sign of a problem.

07.Fault Codes or Error Messages:

Some appliances or systems equipped with electronic pressure switches may display fault codes or error messages when the switch detects a problem.

Refer to the manufacturer’s documentation or service manual for information on interpreting these codes and diagnosing the issue. Fault codes or error messages can provide valuable insights into the nature of the problem and help guide troubleshooting efforts.

08.Testing with a Multimeter:

Use a multimeter to test the continuity and functionality of the pressure switch. Start by disconnecting the power supply to the appliance or system and removing the pressure switch from its housing.

Set the multimeter to the continuity or resistance setting and test the continuity across the switch terminals while applying and releasing pressure to the switch. A lack of continuity or resistance readings that do not change with pressure variations may indicate a faulty pressure switch.

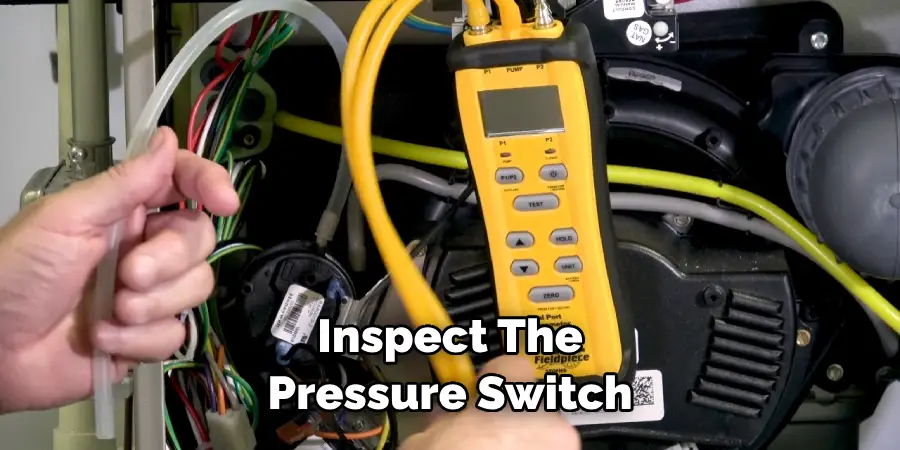

09.Inspecting Pressure Tubing:

Check the pressure tubing or hose connected to the pressure switch for any signs of damage, blockages, or leaks.

A damaged or blocked pressure tubing can prevent the pressure switch from accurately detecting changes in pressure, leading to malfunctioning or erratic behavior. Replace any damaged tubing and ensure that it is properly connected and free from obstructions.

10.Consulting a Professional:

If you are unable to identify the cause of the problem or if you are uncomfortable performing troubleshooting or repair tasks yourself, consider consulting a qualified professional or technician.

A professional with experience working on appliances or systems equipped with pressure switches can perform diagnostic tests, identify the underlying issue, and recommend the appropriate course of action to resolve the problem effectively and safely

Signs of a Faulty Pressure Switch

When pressure switches fail, they exhibit specific signs that can alert you to a potential issue long before a complete failure occurs. Recognizing these signs early can be crucial to preventing operational disruptions and maintaining the safety and efficiency of your system. Below are key indicators that your pressure switch might be faulty:

- Unusual Noise: Beyond the audible clicking or humming mentioned earlier, any out-of-the-ordinary noises coming from the system could indicate a malfunctioning pressure switch. Squealing or grinding noises, in particular, suggest internal damage or obstruction.

- Pressure Misreading: If the system’s pressure readings are inconsistent with known values or fluctuate unpredictably, it might be a sign of pressure switch failure. Correct readings are crucial for the switch’s operation, and discrepancies can lead to improper system responses.

- System Does Not Respond to Adjustments: When adjustments to the pressure settings fail to elicit a response from the system or result in unexpected behavior, it’s likely that the pressure switch is not functioning properly. This indicates that the switch may not accurately interpret or respond to the actual pressure conditions.

- Activation Without Pressure Change: A pressure switch activating or deactivating without any actual changes in system pressure is a clear sign of malfunction. This spontaneous behavior can lead to inefficiency, premature wear of the system, or even safety hazards.

Identifying these signs promptly can help avoid more significant issues down the line. Regular maintenance checks and attentive observation of your system’s performance are effective strategies to catch these early warning signs of a faulty pressure switch.

Troubleshooting Common Issues

When faced with a potentially faulty pressure switch, there are several troubleshooting steps you can undertake to diagnose and potentially resolve the issue before seeking professional help. Here’s a comprehensive guide to troubleshooting common problems associated with pressure switches:

- Initial Assessment: Begin by visually inspecting the pressure switch for any obvious signs of damage, corrosion, or loose connections. This initial check can often reveal simple issues that can be rectified without the need for in-depth diagnostics.

- Electrical Testing: Use a multimeter to conduct electrical tests on the pressure switch. Check for continuity and proper resistance levels across the switch’s terminals to ensure it is operating correctly. Inconsistent or unexpected readings could indicate a fault in the switch.

- Pressure System Check: Examine the entire pressure system, including the tubing or hose connected to the switch, for leaks, blockages, or damage. Issues with the pressure system can affect the switch’s operation and lead to incorrect readings or malfunctions.

- Operational Test: Observe the system’s operation for any signs of the pressure switch failing to activate or deactivate at the correct pressure levels. You may need to manually adjust the system’s pressure to test the switch’s responsiveness.

- Reset or Adjust Settings: Some pressure switches have a reset button or allow for manual adjustment of the pressure settings. Refer to the manufacturer’s instructions to reset or adjust the switch properly.

- Cleaning and Maintenance: Dirt, debris, and other contaminants can interfere with the pressure switch’s operation. Carefully clean the switch and its components according to the manufacturer’s recommendations, taking care not to damage any parts in the process.

- Replacement Parts: If specific components of the pressure switch appear worn or damaged, replacing these parts may resolve the issue. Items like the diaphragm, springs, or terminals can often be sourced and replaced individually.

- Consultation and Documentation: If the problem persists after performing these troubleshooting steps, consult the manufacturer’s documentation for more advanced diagnostics or consider reaching out to a professional technician. It’s vital to address issues with pressure switches promptly to ensure the continued safety and efficiency of the system they control.

By systematically approaching troubleshooting with these steps, you can identify and often resolve common issues with pressure switches, improving system reliability and avoiding potential downtime or damage.

Conclusion

In conclusion, recognizing the signs of a bad pressure switch is essential for maintaining the efficiency and safety of various systems.

By understanding the symptoms, performing diagnostic tests, and taking timely action, individuals can prevent equipment malfunction and costly repairs. Regular maintenance and vigilance play key roles in ensuring pressure switches function optimally, thereby avoiding disruptions in operation and potential hazards.

Remember, proactive monitoring and addressing issues promptly can prolong the lifespan of equipment and enhance overall performance. Whether it’s irregular cycling, inaccurate readings, or unusual noises, every symptom provides valuable insight into the health of pressure switches.

Trusting in diagnostic techniques and seeking professional assistance when needed empowers individuals to safeguard their systems and maintain peace of mind. Thanks for reading, and we hope this has given you some inspiration on how to tell if pressure switch is bad!