Threading plastic pipe is a useful skill for various plumbing and construction projects. It allows you to create secure and leak-proof connections between sections of pipe, ensuring durability and functionality in your system.

This process requires the proper tools and techniques for how to thread plastic pipe. Whether you’re working on a home improvement project or a professional installation, understanding the fundamentals of threading plastic pipe is essential for a successful outcome.

Importance of Threading Plastic Pipes

Threading plastic pipes is crucial for creating strong and reliable connections in plumbing systems. Unlike push-fit or adhesive connections, threaded pipes provide a more secure and reusable joint, reducing the likelihood of leaks or failures over time. This is especially important in systems that handle water under pressure or where regular maintenance may require disassembly. Additionally, properly threaded pipes ensure a precise fit, which can enhance the efficiency and longevity of the plumbing system. Understanding the importance of this technique is key to ensuring the success and integrity of your project.

Tools and Materials Needed

Before you start threading plastic pipe, it’s important to gather all the necessary tools and materials. Having everything on hand will make the process smoother and more efficient. Here’s what you’ll need:

- Plastic Pipe: Select the appropriate diameter and type of plastic pipe for your project, such as PVC or CPVC.

- Pipe Threading Die: A threading die specifically designed for use with plastic pipes to ensure clean and accurate threads.

- Pipe Cutter or Saw: For cutting the plastic pipe to the desired length. Make sure to use a tool capable of making clean, straight cuts.

- Deburring Tool: To remove burrs or rough edges from the cut ends of the pipe. A smooth edge ensures better threading and fit.

- Threading Oil or Lubricant: Reduces friction and prevents the pipe from cracking during the threading process.

- Vise or Pipe Clamp: To securely hold the pipe in place while threading, ensuring stability and precision.

- Measuring Tape: To accurately measure pipe lengths and ensure proper thread placement.

- Marker or Pencil: For marking where to cut or begin threading.

- Protective Gear: Such as safety glasses and gloves to protect your eyes and hands while working.

Having these tools and materials prepared in advance will help you perform the threading process with accuracy and confidence.

10 Methods How to Thread Plastic Pipe

1. Using a Pipe Threading Machine

A pipe threading machine offers the most efficient and precise method for threading plastic pipes, especially for larger projects. Begin by securing the plastic pipe in the machine’s vise. Use a pipe cutter to ensure a clean and square end, as this will directly impact the quality of the thread. Apply a thread-cutting lubricant specifically designed for plastic to reduce friction. Slowly engage the threading dies, ensuring steady and even pressure. Monitor the process closely to prevent the plastic from overheating or cracking. Once the threads are formed, remove the pipe and clean off any debris before use.

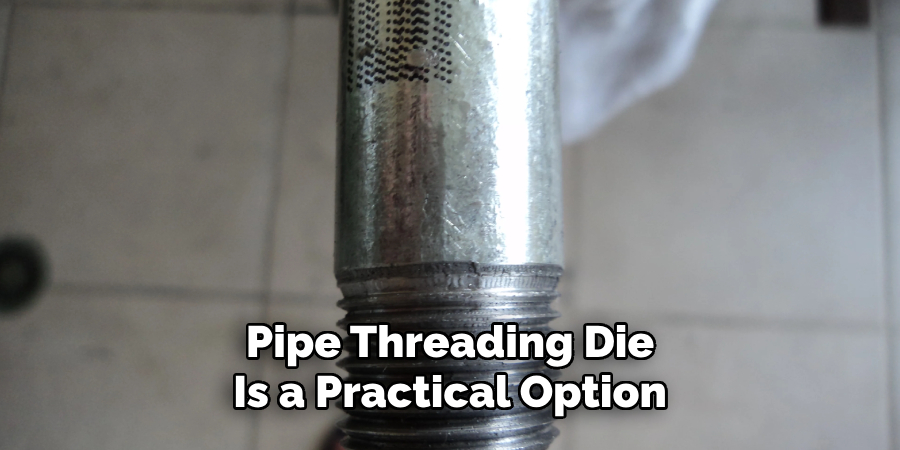

2. Manual Threading with a Handheld Die

For smaller jobs or limited access areas, a handheld pipe threading die is a practical option. Start by clamping the pipe securely in a vise to prevent movement. Cut the end of the pipe squarely using a PVC cutter or a fine-toothed saw. Place

the threading die onto the pipe’s end and apply even pressure while turning it clockwise. Ensure you’re using a die designed for plastic pipes to avoid damage. Periodically reverse the die to clear out shavings and reduce resistance. Clean the threads thoroughly once complete.

3. Choosing the Right Threading Dies

Using the correct threading dies is critical for threading plastic pipes effectively. Dies designed for plastic materials are typically made from softer metals or have specialized coatings to prevent excessive wear and tear on the pipe. Standard dies for metal pipes are too aggressive and can strip or crack plastic materials. Always check the die’s specifications to ensure compatibility with the pipe material and diameter.

4. Heating the Pipe for Easier Threading

In certain cases, gently heating the pipe can make threading easier by softening the plastic. Use a heat gun or warm water to evenly heat the pipe’s end, ensuring it becomes pliable without deforming. Once heated, proceed with threading using a machine or handheld die. The softened plastic reduces the risk of cracking and allows the die to cut smoother threads. However, be cautious not to overheat, as this can compromise the pipe’s structural integrity.

5. Applying Threading Lubricants

Lubrication is crucial when threading plastic pipes to minimize friction and heat buildup. Use a lubricant specifically formulated for plastic materials, as standard oils or greases can degrade the pipe. Apply a generous amount to the pipe’s end and the threading die before starting. Reapply as needed during the threading process to ensure smooth operation and protect the pipe from damage.

6. Using Threaded Couplings

If threading the pipe itself isn’t feasible, consider using threaded couplings as an alternative. These fittings have internal threads designed to mate with threaded pipes or connectors. Cut the plastic pipe to the desired length and insert it into the coupling. Secure the connection with PVC cement or a compatible adhesive to create a reliable joint. This method eliminates the need for direct threading while still achieving a threaded connection.

7. Creating Threads with a Thread Tap

Thread taps are another effective tool for threading plastic pipes, especially for internal threads. Begin by clamping the pipe securely and drilling an appropriately sized hole at the desired location. Insert the thread tap into the hole and rotate it clockwise to create threads. Use steady pressure and back the tap out periodically to clear shavings. This method is ideal for custom applications where external threading isn’t practical.

8. Using Threaded Inserts

Threaded inserts can provide a durable solution for plastic pipes that require threaded connections. Drill a hole at the end

of the pipe and install a threaded insert using a heat tool or adhesive. Once secured, the insert provides a sturdy threaded interface that can withstand repeated use without compromising the pipe’s integrity. This method is commonly used in high-pressure applications or where frequent disassembly is required.

9. Maintaining Thread Consistency

Consistency is vital when threading plastic pipes to ensure a leak-proof connection. Always measure and mark the pipe’s end before starting to ensure accurate thread alignment. Use calipers to check thread depth and spacing as you work. Any inconsistencies can lead to improper connections and potential leaks, so take your time and double-check your work.

10. Inspecting and Testing the Threads

Once threading is complete, inspect the threads carefully for defects such as burrs, uneven cuts, or cracks. Use a thread gauge to verify the accuracy of the threads. Test the connection by threading a compatible fitting onto the pipe and checking for a snug fit. Apply thread sealant or Teflon tape before assembling the final connection to ensure a watertight seal.

Things to Consider When Threading Plastic Pipes

Threading plastic pipes requires careful planning and attention to detail to ensure successful results. Here are some key factors to consider:

- Material Compatibility

Not all plastic pipes are suitable for threading. Check the pipe material specifications to confirm it can withstand the threading process. Pipes made from softer plastics like PVC are more suitable, while brittle materials may crack under pressure.

- Proper Tools and Equipment

Always use tools specifically designed for plastic pipes to avoid damage. Sharp dies, smooth thread taps, and appropriate cutters make the process easier and prevent unnecessary wear.

- Pipe Wall Thickness

Ensure the pipe has adequate wall thickness to accommodate threads without compromising its strength. Thin-walled pipes might not support threading and could lead to weakened connections.

- Environmental Conditions

Consider the environment where the threaded pipe will be used. Temperature fluctuations, chemical exposure, or high pressures can impact the durability of the threads. Use materials and thread sealants that are compatible with the operating conditions.

- Safety Precautions

Threading processes, especially when using machines, can generate sharp edges, heat, and debris. Wear appropriate safety gear, such as gloves and goggles, to protect yourself during the operation.

- Thread Standards

Ensure the threads you create comply with the required standard sizes, such as NPT or BSP, to maintain compatibility with other fittings and components.

By keeping these factors in mind, you can achieve precise, durable threads and extend the lifespan of your plastic piping system.

Conclusion

Threading plastic pipes requires careful preparation, the right tools, and attention to detail. Each of these ten methods provides unique advantages, allowing you to choose the most suitable approach for your project. Whether you opt for a machine threading process or alternative techniques like threaded inserts or couplings, following these detailed instructions will help you achieve secure, reliable connections. Be sure to follow all instructions on how to thread plastic pipe carefully, and always consult an expert when in doubt.