When working with PEX piping, using a pipe expander is an essential skill for creating secure and durable connections. A PEX pipe expander stretches the pipe to fit snugly over a fitting, ensuring a watertight seal once the pipe contracts.

This tool is commonly used in plumbing and radiant heating systems, offering an efficient and reliable way to join pipes without the need for glue, solder, or clamps. This guide explores the key aspects of how to use PEX pipe expander. Before starting, it’s important to understand the proper techniques and safety precautions to achieve the best results.

What is a PEX Pipe Expander?

A PEX pipe expander is a specialized tool designed for expanding cross-linked polyethylene (PEX) pipes, allowing them to fit securely over expansion fittings. This tool works by inserting a cone-shaped head into the end of the PEX pipe and gradually stretching it through a series of expansions. Once expanded, the pipe is slipped over a fitting, and as it contracts, it forms a strong, leak-proof connection. PEX pipe expanders come in both manual and power-operated varieties, offering versatility for different projects and levels of expertise. They are an essential component in modern plumbing systems due to their reliability, ease of use, and the elimination of adhesives or additional fasteners.

Types of PEX Expanders

PEX expanders come in two main types: manual expanders and power-operated expanders.

Manual PEX Expanders

Manual expanders are handheld tools that require physical effort to operate. These tools are ideal for smaller projects or situations where portability is key. They are lightweight, affordable, and easy to maintain, making them a good choice for DIY enthusiasts or occasional plumbing work. However, they may require more time and effort compared to power-operated models.

Power-Operated PEX Expanders

Power-operated expanders are designed for efficiency and ease of use, making them ideal for larger or more complex projects. These devices rely on electricity or a battery to operate, significantly reducing the manual effort required. They are faster and more consistent, ensuring accurate and uniform expansion every time. While they tend to be more expensive than manual models, their speed and convenience often make them worthwhile for professionals or frequent users.

By choosing the right type of PEX expander for your project, you can ensure better results and improved efficiency in your plumbing or heating installations.

Preparing for the Job

Before using a PEX pipe expander, proper preparation is essential to ensure safety and effectiveness. Start by gathering all the necessary tools and materials, including the PEX pipe expander, PEX piping, expansion fittings, and any required accessories. Make sure the PEX pipes are cut cleanly and squarely using a PEX pipe cutter, as uneven cuts can compromise the quality of the connection. Inspect the expander tool to ensure it is in proper working condition, checking for any wear or damage on the expansion head.

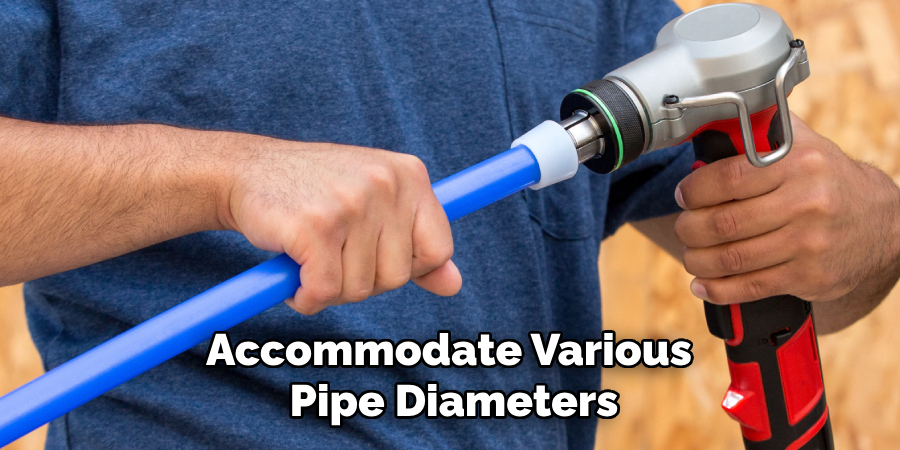

Select the appropriate expansion head size that matches the diameter of the PEX pipe you are working with, and securely attach it to the tool. If using a power-operated expander, ensure the battery is fully charged or that the tool is connected to a reliable power source. Safety precautions are also vital—always wear safety glasses and gloves to protect yourself from potential injuries while operating the tool.

Creating a clean, clutter-free workspace is equally important to avoid accidents and maintain efficiency. Proper preparation will help set the stage for a smooth and successful installation process.

10 Methods How to Use Pex Pipe Expander

1. Understanding the Tool and Its Components

Before using a PEX pipe expander, familiarize yourself with its components. Most PEX pipe expanders consist of a handle, a rotating expansion head, and a mechanism that drives the expansion. Expansion heads are usually interchangeable to accommodate various pipe diameters. Identify the correct head for your pipe size and ensure it is properly secured. Understanding the tool’s mechanics will ensure a smooth operation and prevent mishandling.

2. Choosing the Right PEX Type

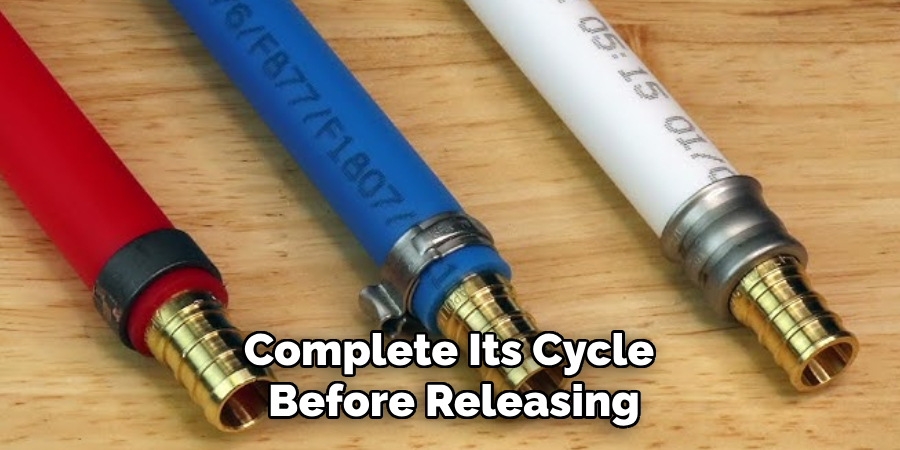

PEX comes in three main types: PEX-A, PEX-B, and PEX-C. While a pipe expander is primarily used for PEX-A, knowing the differences is vital. PEX-A is the most flexible and compatible with expansion tools. Ensure your project uses PEX-A for the expander to work effectively. Using the wrong PEX type may result in improper sealing and could compromise the integrity of your plumbing system.

3. Inspecting and Preparing the Pipe

Proper preparation is key to achieving a reliable connection. Begin by cutting the PEX pipe cleanly using a pipe cutter. Ensure the cut is perpendicular to the pipe’s length for an even expansion. Check the pipe for any imperfections, such as cracks or uneven surfaces. Remove debris or burrs from the cut end, as these can hinder the expansion process or lead to leaks. A well-prepared pipe ensures a smoother expansion and a secure connection.

4. Inserting the Expansion Head

Select the appropriate expansion head based on the pipe’s diameter, typically marked on the tool and the head itself. Attach the head securely to the tool’s expansion mechanism. Make sure it is firmly in place to avoid any slipping during operation. Many modern expanders feature auto-rotating heads to evenly expand the pipe, but if your tool requires manual rotation, ensure you’re prepared for consistent turns.

5. Expanding the Pipe

Position the expander head into the cut end of the PEX pipe. Squeeze the tool’s handle to begin expanding. If your tool is a manual model, maintain consistent pressure to ensure uniform expansion. For powered expanders, let the tool complete its cycle before releasing. Rotate the pipe slightly between expansions if the tool does not auto-rotate. Expanding evenly prevents weak spots that could lead to leaks or fitting failure.

6. Inserting the Fitting Quickly

Once the pipe is expanded, you have a limited window of time to insert the fitting before the PEX returns to its original size. Quickly insert the fitting into the expanded pipe until it’s fully seated. The pipe will contract around the fitting, creating a tight, leak-proof seal. Ensure the fitting is aligned correctly and pushed in firmly, as any misalignment can cause sealing issues.

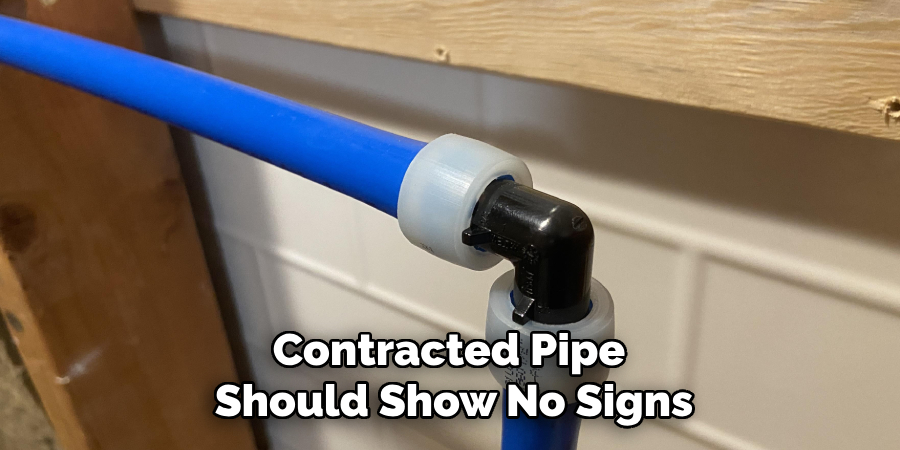

7. Allowing Proper Recovery Time

After inserting the fitting, allow the PEX pipe to contract and recover fully. This process typically takes a few seconds to a few minutes, depending on the pipe’s temperature and diameter. Avoid disturbing the connection during this time, as movement can disrupt the seal. Patience at this stage ensures a long-lasting and durable connection.

8. Practicing Temperature Control

PEX pipe is sensitive to temperature. Cold pipes can be more challenging to expand, while overly heated pipes may weaken. If working in cold environments, consider warming the pipe with a heat gun or hot water before expansion. However, avoid overheating, as this can compromise the pipe’s structural integrity. Proper temperature management ensures smooth expansion and optimal sealing.

9. Inspecting the Final Connection

Once the PEX pipe has contracted fully around the fitting, inspect the connection for any visible gaps or misalignments. Tug gently on the fitting to confirm it is secure. A properly expanded and contracted pipe should show no signs of loosening. If the connection appears faulty, remove the fitting, cut the pipe, and repeat the process to ensure a proper seal.

10. Maintaining the Tool

A well-maintained PEX pipe expander ensures consistent performance. After each use, clean the tool to remove any debris or buildup. Lubricate moving parts as recommended by the manufacturer to prevent wear and tear. Regularly inspect the expansion heads for damage and replace them if necessary. Proper tool maintenance not only extends the life of your equipment but also ensures reliable connections in future projects.

Safety Considerations

Ensuring safety while using a PEX pipe expander is paramount to prevent accidents and maintain an efficient workflow. Always start by wearing appropriate personal protective equipment (PPE), including safety glasses and gloves, to shield yourself from potential hazards such as flying debris or accidental slips. Ensure the workspace is clean, well-lit, and free from clutter to minimize the risk of tripping or mishandling the tool.

Never operate a damaged or malfunctioning expander, and inspect the tool for wear and tear before each use. Follow the manufacturer’s guidelines for proper tool usage and avoid exceeding the tool’s recommended limits. Additionally, when working with powered expanders, ensure cords are in good condition, batteries are charged, and cables are placed to avoid tangling, which could pose a tripping hazard. By adhering to these safety practices, both your well-being and the quality of your work will be protected.

Conclusion

Using a PEX pipe expander effectively requires preparation, precision, and attention to detail. By understanding the tool, selecting the correct PEX type, and following the proper steps for expansion and fitting, you can ensure strong, leak-proof connections for your plumbing projects. Remember to prioritize safety, maintain your tools, and consider environmental conditions to achieve optimal results. Thanks for reading, and we hope this has given you some inspiration on how to use PEX pipe expander!