Are you tired of using traditional cleaning methods that are time-consuming and have a strong chemical odor? Look no further; pipe solvent is here to make your life easier.

Using pipe solvent is essential in ensuring strong and reliable connections when working with PVC or CPVC pipes. This specialized adhesive chemically bonds the pipes and fittings, creating a durable seal that prevents leaks.

Proper application of pipe solvent requires attention to detail and adherence to safety guidelines to ensure the connection is effective and long-lasting.

Whether you’re tackling a DIY plumbing project or a professional installation, understanding how to use pipe solvent correctly is key to achieving a successful result. Let’s dive into the step-by-step process of using pipe solvent and some valuable tips to keep in mind.

What Are the Benefits of Using Pipe Solvent?

Before we jump into the practical application, let’s take a moment to understand why pipe solvent is a preferred method for connecting pipes.

- Faster and Easier: Unlike traditional methods such as threading or welding, pipe solvent requires no special tools or equipment. It is also a quick process, allowing you to complete your project in minimal time.

- Stronger Bond: The chemical reaction between the solvent and the plastic material creates a strong and permanent bond that can withstand high pressure and temperature variations. This makes it an ideal choice for both residential and commercial applications.

- Versatile: Pipe solvent works on various plastic pipes, such as PVC, CPVC, and ABS, making it a versatile adhesive in your toolkit.

- Cost-effective: Pipe solvent is affordable compared to other pipe connection methods, making it a cost-effective choice for both small and large-scale projects.

What Will You Need?

Before you begin, ensure you have all the necessary tools and materials to avoid any delays or interruptions during the process. Here’s what you’ll need:

- Pipe Solvent: Choose a high-quality, industry-grade pipe solvent from a reputable brand for the best results.

- PVC or CPVC pipes and fittings: Make sure they are clean and debris-free.

- Safety Gear: As pipe solvent contains strong chemicals, it is crucial to wear protective gear such as gloves, goggles, and a respirator mask while working with it.

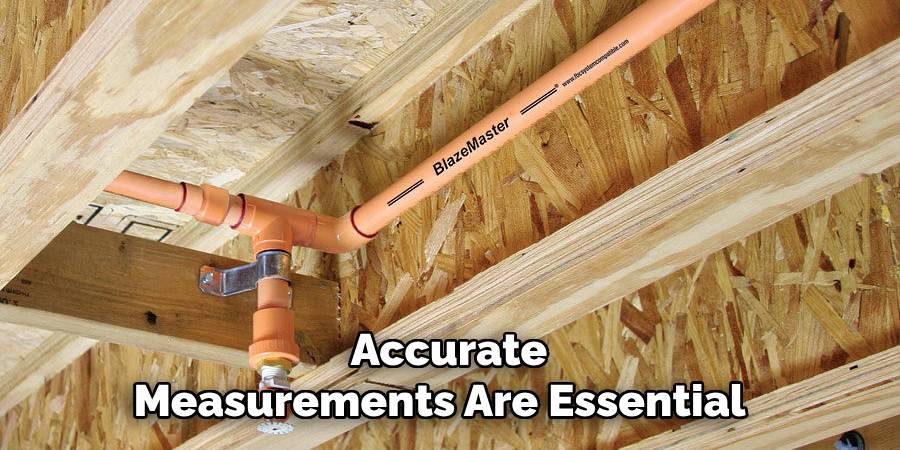

- Measuring Tape: Accurate measurements are essential for precise cuts and connections.

- Towel/Rag: Keep a towel or rag handy to remove any excess solvent.

Once you have all the necessary supplies, you’re ready to begin.

8 Easy Steps on How to Use Pipe Solvent

Step 1: Measure and Cut the Pipes

Using the measuring tape, determine the exact length of the pipe needed for your project. Mark the measurement clearly with a marker. Carefully cut the pipe using a pipe cutter or a hacksaw.

Ensure that the cuts are straight and even to create a proper fit for the connections. Once cut, use sandpaper or a deburring tool to smooth the edges of the pipe to remove any roughness or burrs.

Step 2: Dry-fit the Pipes and Fittings

Before applying any solvent, it’s vital to dry-fit the pipes and fittings to ensure they align correctly and fit snugly. Take the cut pipe and insert it into the corresponding fitting. Check that the connection is tight and there are no gaps between the pipe and the fitting.

Rotate the pipe slightly in the fitting to confirm it has a proper seal without feeling too loose or tight. This step is crucial as it allows you to make necessary adjustments or re-cuts before proceeding.

Once you are satisfied with the fit, mark the pipe and fitting with a pencil or marker along the edges where they join. These marks will serve as a guide when applying the solvent to ensure the final assembly aligns precisely as intended.

Step 3: Apply the Solvent Cement

Start by cleaning both the outside of the pipe and the inside of the fitting with a pipe cleaner or primer designed for PVC. This removes dirt, grease, and any residue that might prevent a proper bond. Once cleaned, apply an even layer of solvent cement to the outside of the pipe and the inside of the fitting using the applicator provided with the cement.

Be thorough, but avoid over-applying, as excess cement can create a messy joint. Quickly insert the pipe into the fitting while twisting slightly to evenly distribute the cement and align the marks made during dry-fitting. Hold the connection in place for 15–30 seconds to allow the bond to set.

Wipe away any excess cement with a cloth before it hardens. Allow sufficient curing time as specified by the solvent cement instructions before putting the assembly into use.

Step 4: Test the Connection

Once the solvent cement has fully cured, it’s time to test the connection for leaks. Begin by ensuring the assembly is securely connected to the system, and all components are in place.

Gradually introduce water or the appropriate material into the system, monitoring the joint closely for any signs of leakage. If a leak is detected, carefully inspect the joints for gaps or cracks and apply additional solvent cement if necessary after cleaning the area.

Repeat the test once repairs are made. Proper testing ensures the integrity of the connection and prevents potential failures in the future.

Step 5: Final Inspection and Cleanup

After successfully testing the connection, perform a final inspection to ensure the assembly meets the required standards. Check all joints, fittings, and connections for proper alignment and ensure there are no visible defects or irregularities.

Remove any remnants of solvent cement from the exterior of the assembly and clean the surrounding area to maintain a neat and professional finish. Proper cleanup and inspection will ensure the longevity and reliability of the system.

Step 6: Documentation

Once the assembly is complete and all inspections have been successfully performed, document the process and any relevant details for future reference.

This includes recording the materials used, dates of installation, and results of any tests conducted. Developing a maintenance schedule is also crucial to ensure the system’s long-term performance.

Regularly inspect the assembly for wear or damage and address any issues promptly to avoid potential failures. Proper documentation and maintenance contribute to the system’s efficiency and durability over time.

Step 7: Final Testing and Commissioning

After completing the assembly and documentation, the final step is to conduct thorough testing and commissioning of the system. Begin by performing pressure or flow tests to confirm that the system operates as intended and that there are no leaks or other issues.

Verify all connections, joints, and components to meet the required standards and specifications. Once testing is completed, the system can be brought into service. Ensure end users are informed about the system’s operation and specific usage guidelines.

Proper final testing and commissioning ensure the system is fully functional and ready for long-term use.

Step 8: Regular Maintenance and Inspection

To ensure the ongoing reliability and performance of the system, establish a routine schedule for maintenance and inspection. This involves checking for wear and tear on critical components, cleaning parts prone to buildup or blockages, and replacing damaged or aging elements.

Regularly verify system calibration and performance metrics to identify potential inefficiencies early. Keeping detailed maintenance logs can help track the system’s history and provide valuable insights for future troubleshooting. Proactive maintenance extends the system’s lifespan and reduces the risk of unexpected downtime.

By following these steps, you can effectively and efficiently assemble a PVC piping system that meets the required standards and provides reliable performance for years.

5 Things You Should Avoid

- Skipping Surface Preparation: Always clean and dry the surfaces of the pipes before applying the solvent. Dirt, grease, or moisture can compromise the bond and lead to leaks over time.

- Using Excessive Solvent: Applying too much solvent can weaken the joint or cause it to overflow, leaving a messy and potentially unsafe result. Use just enough to coat the surfaces evenly.

- Not Allowing Proper Drying Time: Failing to wait for the recommended drying or curing time can make weak joints prone to failure. Always refer to the manufacturer’s drying guidelines.

- Ignoring Ventilation: Pipe solvent emits strong fumes that can be harmful when inhaled in poorly ventilated spaces. Always work in a well-ventilated area or use protective respiratory equipment.

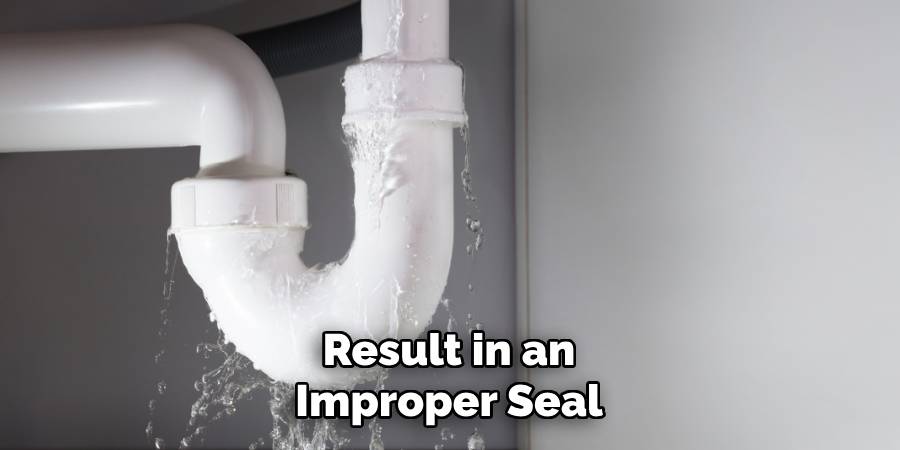

- Using the Wrong Type of Solvent: Different pipe materials require specific solvents. Using the incorrect solvent can damage the pipes or result in an improper seal. Confirm compatibility before use.

By avoiding these common mistakes, you can ensure a successful and long-lasting solvent joint that will withstand the test of time.

Conclusion

How to use pipe solvent effectively requires careful attention to detail and adherence to best practices.

Begin by ensuring that you have selected the correct type of solvent for your pipe material, as compatibility is crucial. Thoroughly prepare the pipe surfaces by cleaning and drying them to remove any dirt, grease, or debris.

Apply the solvent evenly and sparingly to avoid excess runoff or weakening the joint. Always allow sufficient drying or curing time, as the manufacturer recommends, to ensure a secure bond. Lastly, work in a well-ventilated area or use appropriate protective gear to minimize exposure to harmful fumes.

Following these steps, you can achieve durable and reliable solvent joints that perform well over time.