A tube bender is a tool designed to create precise bends in pipes or tubing without causing damage or kinks. Whether you are working with metal, plastic, or other materials, understanding how to use a tube bender properly is essential for achieving clean, accurate results.

This guide will walk you through the basics of how to use tube bender safely and effectively, helping you tackle various projects with confidence.

What is a Tube Bender?

A tube bender is a specialized tool used to bend pipes or tubes to a specific angle or shape. It is commonly utilized in industries such as plumbing, automotive, construction, and manufacturing, where precise tubing configurations are required.

Tube benders come in various types, including manual, hydraulic, and electric models, each suited to different materials and project scales.

By applying the correct method and using the appropriate type of bender, users can achieve clean bends without collapsing or weakening the tube, ensuring both functionality and structural integrity.

Benefits of Using a Tube Bender

Using a tube bender offers numerous advantages, particularly when precision and efficiency are key. One of the primary benefits is the ability to achieve smooth, uniform bends without compromising the integrity of the tubing material.

This reduces the risk of cracks, kinks, or other deformities that can weaken the structure. Tube benders are also highly versatile, allowing users to work with a variety of materials and diameters, making them suitable for a wide range of applications, from plumbing to automotive and industrial projects.

Additionally, by using a tube bender, you can save time and effort compared to manual bending methods, ensuring consistent, professional-quality results every time.

Types of Tube Benders

There are several types of tube benders available, each designed for specific applications and materials. Understanding the different types can help you choose the right tool for your project:

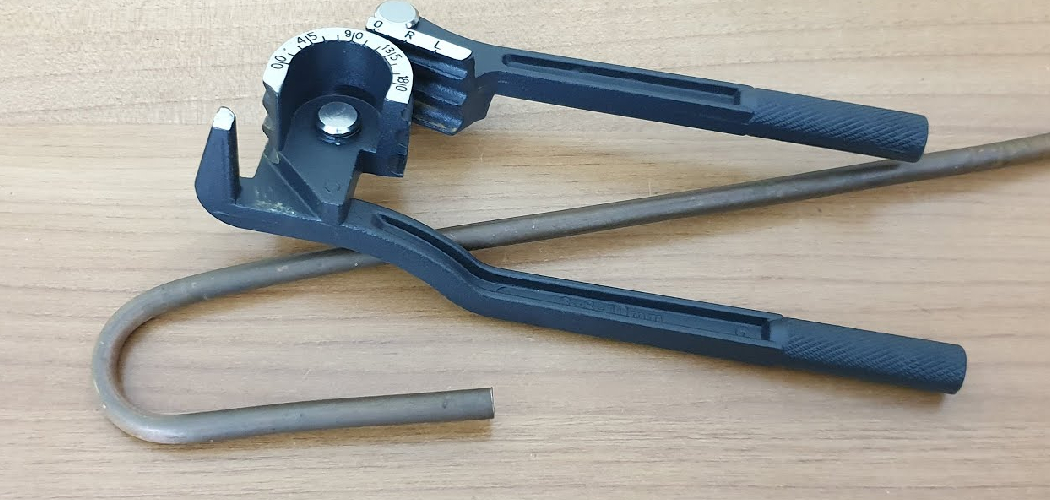

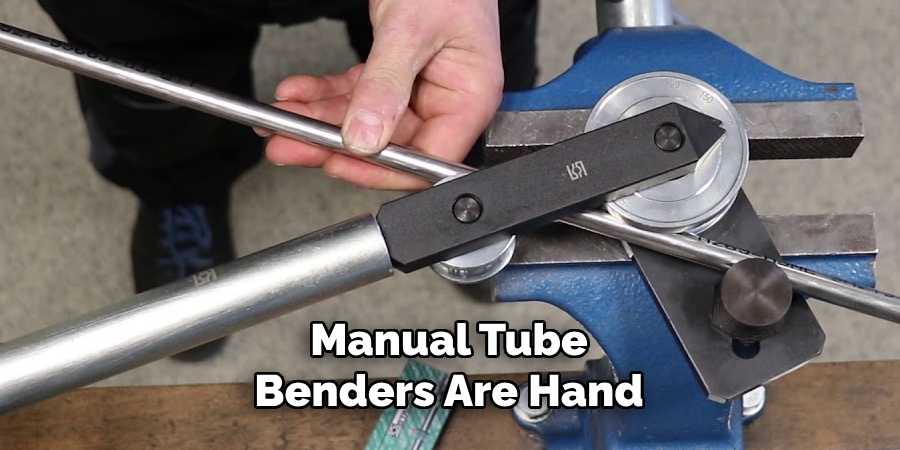

1. Manual Tube Benders

Manual tube benders are hand-operated tools that are perfect for smaller projects and lightweight materials such as soft metals or plastics. They are portable, cost-effective, and easy to use, making them ideal for DIY enthusiasts and smaller-scale tasks. However, they may require more physical effort and precision compared to other types.

2. Hydraulic Tube Benders

Hydraulic tube benders use hydraulic pressure to create bends, making them suitable for heavier-duty work and thicker materials such as steel or aluminum. They provide greater bending power with less physical exertion, making them a popular choice for professionals in industries like construction and automotive repair.

3. Electric Tube Benders

Electric tube benders are fully automated and use an electric motor to perform bends with high precision. These benders are highly efficient and are often used for industrial applications requiring large-scale or repetitive bending tasks. They are ideal for projects that demand accuracy and consistency in a short amount of time.

4. CNC Tube Benders

CNC (Computer Numerical Control) tube benders are advanced machines that automate the bending process using pre-programmed instructions.

They are used for complex and custom tubing configurations, making them ideal for manufacturing, aerospace, and other high-precision industries. While they are the most technologically advanced, they also come with a higher cost and are typically used in commercial settings.

Each type of tube bender serves a specific purpose, and selecting the right tool depends on the material, the project scope, and the level of precision required.

10 Methods How to Use Tube Bender

1. Understand the Type of Tube Bender

Before starting, familiarize yourself with the type of tube bender you’re using. Tube benders come in manual, hydraulic, and electric varieties, each suited for different applications.

Manual tube benders are ideal for small projects and soft metals, while hydraulic and electric models are better for larger projects and tougher materials. Knowing your tool’s capabilities and limitations is essential for achieving accurate bends.

2. Choose the Correct Tubing Material

Ensure the tubing material is compatible with the bender and suitable for your project. Soft metals like aluminum, copper, and mild steel are easier to bend, while stainless steel and titanium require more force and precision. Check the manufacturer’s specifications for the bender to confirm it can handle the material’s thickness and diameter.

3. Measure and Mark the Tubing

Accurate measurements are crucial when using a tube bender. Use a measuring tape or ruler to determine where the bend should occur. Mark the tubing with a permanent marker or scribe to ensure precision. For multiple bends, plan the sequence and spacing to avoid errors. Proper marking minimizes waste and ensures consistent results.

4. Set the Bender to the Desired Angle

Most tube benders have angle markings to guide the bending process. Adjust the bender’s settings to match the desired bend angle, typically measured in degrees. For manual benders, align the tubing with the die and clamp it securely. Ensure the angle settings are accurate to achieve the desired shape without over-bending or under-bending.

5. Secure the Tubing Firmly

Secure the tubing in the bender’s clamps or dies to prevent movement during the bending process. Use the appropriate size die to match the tubing diameter. Tighten the clamps evenly to avoid damaging the tubing or creating uneven bends. Properly securing the tubing ensures a smooth and consistent bend.

6. Perform the Bend Gradually

Apply steady, even pressure to bend the tubing gradually. For manual benders, pull or push the handle smoothly to avoid sudden movements that could kink or deform the tubing. For hydraulic or electric benders, operate the controls slowly and monitor the progress. Gradual bending reduces stress on the material and ensures a clean, professional finish.

7. Check the Bend Radius

The bend radius is the curve’s inner measurement and plays a crucial role in maintaining the tubing’s integrity. Use a radius gauge or template to check the bend radius during and after bending. Ensure the radius matches the project requirements to avoid structural weaknesses or improper fits. Consistent radius checks prevent costly errors.

8. Avoid Over-Bending

Over-bending can weaken the tubing and result in an incorrect shape. Stop bending just before reaching the desired angle and check the alignment. If necessary, make minor adjustments to achieve the exact angle. Over-bending is challenging to correct and can compromise the tubing’s strength and appearance.

9. Deburr and Clean the Tubing

After bending, inspect the tubing for burrs or sharp edges that may have formed during the process. Use a deburring tool or file to smooth the edges and remove any debris. Cleaning the tubing ensures a professional finish and prevents damage during installation. For critical applications, check for cracks or deformities that could compromise the tubing’s performance.

10. Test the Fit and Make Adjustments

Once the tubing is bent, test its fit within the intended application. Align the tubing with the system or structure to ensure proper placement and clearance. If adjustments are needed, use the tube bender carefully to avoid overworking the material. Testing the fit ensures the tubing meets the project’s specifications and functions as intended.

Maintenance and Upkeep

Proper maintenance and regular upkeep of tube benders are essential to ensure their longevity and optimal performance. Follow these steps to keep your tube bender in excellent working condition:

1. Clean After Each Use

After completing a project, clean the tube bender to remove dust, debris, and metal shavings that may have accumulated. Use a soft cloth or brush to wipe down the surfaces and ensure the dies and clamps are free from dirt. Keeping the machine clean prevents build-up that could affect its function over time.

2. Lubricate Moving Parts

Lubricate the moving parts, such as hinges, gears, and pistons, to maintain smooth operation. Use a high-quality lubricant recommended by the manufacturer. Regular lubrication reduces friction and wear, prolonging the life of your tube bender.

3. Inspect for Wear and Damage

Periodically inspect your tube bender for signs of wear, cracks, or damage. Pay special attention to the dies, clamps, and handles, as these components experience the most stress. Replace worn or damaged parts promptly to avoid compromising the accuracy and safety of the tool.

4. Check Calibration

Ensure that the bender is properly calibrated to produce accurate bends. Over time, settings may drift due to use or external factors. Verify angle markings and adjust the calibration as needed. Proper calibration is especially important for electric and CNC models.

5. Store in a Dry Environment

Store the tube bender in a clean, dry place to prevent rust and corrosion. Use protective covers or cases to shield it from moisture and dust. Proper storage minimizes the risk of long-term damage and keeps the tool ready for use.

Conclusion

Mastering the use of a tube bender requires proper technique, attention to detail, and adherence to safety guidelines. By following the outlined steps, you can achieve precise, consistent results for a variety of applications.

Maintaining your tube bender through regular cleaning, lubrication, and inspections ensures its reliability and longevity, saving time and effort on future projects. Now that you know how to use tube bender, try it yourself today and feel good about completing such a big DIY job!