Venting a high-efficiency furnace is a critical aspect of ensuring its optimal performance and maintaining a safe home environment. Unlike conventional furnaces, high-efficiency models have distinct venting requirements that contribute to their energy efficiency. Proper venting not only expels combustion byproducts but also prevents potential hazards associated with gas appliances.

In this article, we will delve into the essential steps and considerations for how to vent high efficiency furnace. From understanding venting types to ensuring proper installation, this guide aims to empower homeowners with the knowledge needed to navigate the intricacies of venting systems.

So, whether you’re upgrading to a high-efficiency furnace or seeking to enhance your understanding of existing systems, join us on this informative journey to master the art of venting a high-efficiency furnace for a safer and more efficient home heating experience.

Importance of Proper Ventilation for High-Efficiency Furnaces

Understanding the proper ventilation for high-efficiency furnaces is crucial for their efficient operation and the safety of your home. These furnaces typically require direct-vent systems that expel exhaust gases directly outside, without the need for a traditional chimney. This direct-venting method is essential because high-efficiency furnaces produce cooler flue gases due to their design to extract more heat from these gases before expelling them.

Therefore, these gases can condense if not vented properly, causing damage to the furnace and potential health risks. It’s important to ensure that the vent pipes are made of materials like PVC to withstand the acidic condensation produced and are correctly sized and sloped to facilitate the removal of these gases.

Proper installation and regular maintenance of the venting system are non-negotiable to ensure your high-efficiency furnace operates safely and effectively.

Venting Requirements for High-Efficiency Furnace Systems

High-efficiency furnace systems, also known as condensing furnaces, have specific venting requirements that must be meticulously followed to ensure safe and efficient operation. Firstly, these units typically need a direct vent or two-pipe system – one pipe to bring fresh air in from the outside for combustion and the other to expel the cool, moist exhaust gases.

The use of PVC, CPVC, or ABS pipes is often recommended due to their resistance to the corrosive condensate produced by these furnaces. The vent pipes’ size and length should adhere to the manufacturer’s specifications to ensure proper exhaust flow and avoid backdraft, which could introduce harmful gases back into the home.

Additionally, the exhaust vent must terminate outside the house in a location that minimizes the risk of re-entry of exhaust gases into the building and avoids damage from the acidic condensate to the building’s exterior or the environment. Implementing these venting requirements is essential for the performance and longevity of high-efficiency furnace systems and for the health and safety of the home’s occupants.

Differences Between Standard and High-Efficiency Furnace Venting Systems

Standard and high-efficiency furnace venting systems differ significantly in their design and operation, reflecting the advancements in furnace technology. The most notable difference lies in the type of venting each requires due to the differing temperatures of the exhaust gases they produce.

Standard, or mid-efficiency, furnaces often expel hotter gases, making it safe to vent through metal chimneys or B-vents that rely on natural draft to expel exhaust outdoors. These systems work well with the higher temperatures but are not suitable for the cooler, moisture-laden exhaust of high-efficiency units.

High-efficiency furnaces, on the other hand, extract more heat from the gas, resulting in cooler, condensing flue gases that require special venting considerations. These furnaces typically use PVC, CPVC, or ABS piping for venting, as these materials can withstand the acidic condensation produced.

Furthermore, high-efficiency systems usually employ a direct-vent or sealed combustion system, which does not use indoor air for combustion, thereby reducing heat loss and improving safety and efficiency. This design difference fundamentally changes the installation, maintenance, and operational needs of high-efficiency systems, emphasizing the importance of understanding these distinctions to ensure proper and safe furnace operation.

Selecting the Right Venting System

Choosing the appropriate venting system for a high-efficiency furnace is critical to its efficiency and safety. The selection process begins with understanding the specific requirements of your furnace, as outlined by the manufacturer. High efficiency models almost universally require direct vent systems, but the size and type of piping can vary depending on the furnace’s output and design.

Homeowners should consider the length of the vent run and the number of elbows or turns needed, as these factors can affect the size of the vent pipe required to ensure optimal performance. Furthermore, the location of the vent’s termination is crucial to prevent exhaust gas re-entry and to minimize environmental impact.

Consulting with a professional HVAC technician who can assess your home’s layout and recommend the best venting system is invaluable. This step not only ensures compliance with local building codes but also guarantees that your furnace operates safely, efficiently, and effectively for years to come.

10 Methods How to Vent High Efficiency Furnace

1. Understand Venting Types:

High-efficiency furnaces commonly use either PVC or stainless steel vent pipes for venting. Understand the specific venting type required by your furnace model. PVC pipes are often used for intake, while stainless steel pipes handle exhaust. PVC pipes are less expensive and easier to install, making them a popular choice.

In addition to understanding the specific venting type required by your furnace model, it is also important to understand the differences between PVC and stainless steel vent pipes. This knowledge can help you make an informed decision when choosing which type of vent pipe to use for your furnace.

One key difference between PVC and stainless steel vent pipes is their durability. PVC pipes are more prone to damage from weather, such as extreme temperatures, sunlight exposure, and wind. On the other hand, stainless steel pipes are highly durable and can withstand harsh weather conditions.

2. Install Vent Pipes Correctly:

Proper installation of vent pipes is crucial for the safe operation of a high-efficiency furnace. Follow the manufacturer’s guidelines and local building codes to ensure the correct pitch, support, and termination of vent pipes.

Incorrectly installed pipes can lead to carbon monoxide leaks, back drafting, and even fire hazards. Regular maintenance and inspection of vent pipes is also necessary to ensure their continued function. Once properly installed, vent pipes should remain undisturbed to avoid any compromise in their function.

3. Consider Venting Configurations:

High-efficiency furnaces offer versatile venting configurations, including direct vent, sidewall vent, and concentric venting. Choose the configuration that best suits your home’s layout and meets safety standards. Ventilation is important for proper furnace function and the safety of your home. These options also help with energy costs and efficiency.

Direct venting is an ideal option when there’s no existing chimney, which makes it a popular choice for newly constructed homes. This system uses two pipes: one to carry fresh air in from outside, while another exhausts combustion gases back outside. The pipes can be installed vertically or horizontally, depending on your home’s layout. The direct venting system also has a sealed combustion chamber, which eliminates the risk of backdraft and ensures safe indoor air quality.

Sidewall venting is another popular option for homes without chimneys. This type of venting uses a single pipe that runs through an exterior wall to carry exhaust gases outside. However, sidewall venting may not be suitable for all homes as it requires proper clearance from neighboring windows, doors, and other exterior structures.

4. Locate Vent Termination Point:

Determine the appropriate termination point for the vent pipes, which can include sidewalls, roofs, or chimneys. Ensure the termination location complies with local codes and manufacturer specifications to prevent issues such as back drafting. It is also important to consider the weather conditions in your area and choose a location that will not be affected by wind or rain. If possible, try to locate the termination point in an inconspicuous area to maintain the aesthetic appeal of your home.

Once you have determined the appropriate termination point, make sure that there are no obstructions or potential safety hazards in the vicinity. This includes objects such as trees or nearby power lines. It is important to ensure that the vent pipe has a clear path for exhaust gases to safely leave the home.

In addition to selecting the right termination point, it is also crucial to properly install and secure the vent pipes. Use appropriate materials and techniques recommended by the manufacturer or a professional installer. This will ensure that the venting system functions efficiently and effectively.

5. Check Vent Pipe Sizing:

Verify that the vent pipes are correctly sized for your furnace. Improper sizing can lead to issues like condensation buildup or reduced efficiency. Consult the furnace manual or seek professional advice to ensure proper sizing.

One important aspect of furnace maintenance is checking the size of the vent pipes. This is a crucial step that should not be overlooked, as improperly sized vent pipes can lead to a number of problems.

The first issue that may arise from incorrect vent pipe sizing is condensation buildup. When the pipes are too small for the furnace’s exhaust flow, it can cause moisture to accumulate inside the pipes. This can lead to corrosion and rust, which can damage the furnace and shorten its lifespan.

Furthermore, inadequate vent pipe sizing can also result in reduced efficiency of your furnace. The proper size of vent pipes is crucial for proper air flow and gas combustion. When the pipes are too small, it can cause a restriction in air flow and prevent the furnace from functioning at its optimal level. This can lead to higher energy bills and a shorter lifespan for your furnace.

6. Install Vent Pipe Supports:

Adequately support vent pipes to prevent sagging or misalignment. Use manufacturer-approved support methods, such as straps or brackets, to secure the pipes in place and maintain the proper slope for condensate drainage. Be sure to follow any specific instructions provided by the manufacturer for your particular vent pipe system.

When selecting support methods, consider the size and weight of the pipes, as well as the distance between supports. Typically, vent pipes should be supported every 6 feet horizontally and every 10-12 feet vertically. However, this may vary depending on the type of vent pipe being used and local building codes.

It is important to also consider the material of the vent pipe supports. The most common materials used for supports are metal straps, brackets, and hangers. These materials provide strength and durability, ensuring that the vent pipes remain in place and do not shift or move over time.

7. Address Condensate Drainage:

High-efficiency furnaces produce condensate as a byproduct of the combustion process. Ensure that the condensate drainage system is functioning correctly, with proper slope and no blockages, to prevent damage to the furnace and surrounding areas.

The condensate drainage system is an important component to consider when inspecting a high-efficiency furnace. This system is responsible for removing excess moisture and byproducts from the combustion process, known as condensate, away from the furnace.

One of the main reasons why proper functioning of the condensate drainage system is crucial is to prevent potential damage to both the furnace and the surrounding areas. If the drainage system is not functioning correctly, condensate can build up around the furnace and cause corrosion or water damage. This can lead to expensive repairs or even the need for a new furnace.

8. Check Combustion Air Intake:

Verify that the combustion air intake is unobstructed and free from debris. Proper airflow is essential for combustion efficiency, and any restriction can lead to performance issues or safety concerns. This should be checked regularly, especially in areas with high pollen or debris levels.

It is also important to ensure that the combustion air intake is not blocked by any objects such as furniture or plants. These can restrict airflow and cause issues with proper combustion. Regularly check your intake area and clear away any potential obstructions.

In addition to ensuring proper airflow, it is crucial to inspect the combustion air intake for any signs of damage or deterioration. Weather conditions and external factors can cause the intake to become damaged over time, leading to poor combustion and potential safety hazards.

9. Inspect Venting System Regularly:

Schedule routine inspections of the venting system to identify and address any signs of wear, corrosion, or damage. This proactive approach helps prevent potential issues and ensures the continued safe operation of the furnace. It is recommended to have a professional HVAC technician conduct these inspections every year.

Regular maintenance and cleaning of the venting system is also important. Over time, debris, dirt, and other particles can build up in the vents, obstructing proper air flow. This can cause strain on the furnace and potentially lead to malfunctions or breakdowns. Regularly checking and cleaning the vents can help prevent these issues and keep the furnace running smoothly.

In addition to visual inspections, it is also important to regularly test the venting system for proper air flow. This can be done by lighting a small piece of paper or incense stick near each vent opening while the furnace is running. If the smoke or flame is pulled into the vent, this indicates good air flow. If it is pushed away or remains unaffected, this could be a sign of an obstruction in the vent and should be addressed immediately.

10. Consult a Professional Installer:

If you’re unsure about venting requirements or encounter difficulties during installation, consult a professional HVAC installer. Certified technicians have the expertise to navigate complex venting systems, ensuring compliance with safety standards and optimal furnace performance. They can also provide expert advice on maintaining your furnace and keeping it running smoothly, reducing the risk of future issues.

In addition to installation, a professional HVAC installer can help with regular maintenance and repairs. Regular maintenance not only prolongs the lifespan of your furnace but also helps to keep it operating at peak efficiency. This translates into lower utility bills and a more comfortable home. When it comes to repairs, a professional can quickly diagnose and resolve any issues that may arise, ensuring your furnace is up and running in no time.

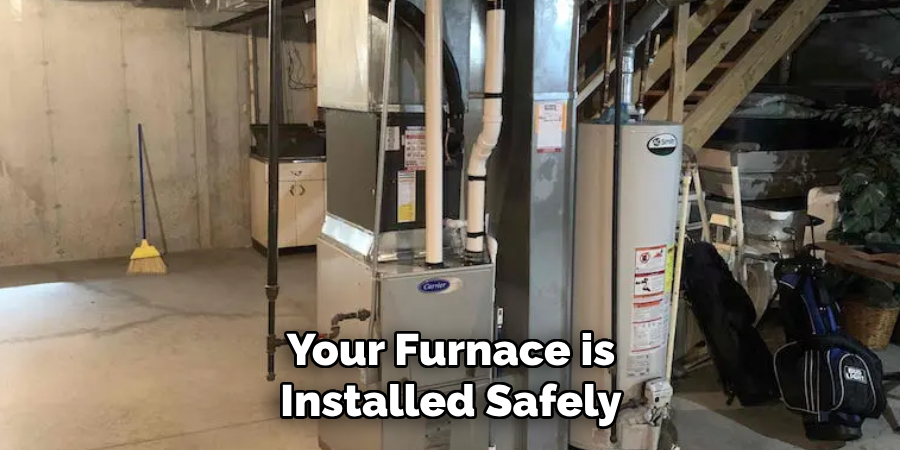

Furthermore, hiring a professional installer helps protect your home and family from potential hazards. Improperly installed furnaces can lead to gas or carbon monoxide leaks, fire hazards, and other safety risks. By relying on a certified technician, you can rest assured that your furnace is installed safely and up to code.

Conclusion

In conclusion, understanding how to vent a high-efficiency furnace is crucial for maintaining safe and efficient operation of heating systems. Proper venting not only ensures the safe expulsion of combustion gases but also maximizes the furnace’s energy efficiency.

By selecting the appropriate venting route, installing vent pipes and components correctly, and conducting thorough safety checks and testing, homeowners and HVAC professionals can mitigate the risk of hazards and optimize furnace performance.

Regular maintenance and monitoring of the venting system are essential for identifying and addressing potential issues promptly. Hopefully, this article gave you some helpful tips about how to vent high efficiency furnace successfully, so now that you have the proper knowledge on how to get the job done, why not give it a try today?