Winterizing a good pump is crucial for homeowners who wish to protect their water supply and plumbing from the harsh effects of cold weather. Failing to take proper precautions can lead to issues such as frozen pipes, burst pumps, and significant loss of water supply during the winter months, which could result in costly repairs and disruptions.

Understanding how to winterize a well pump safeguards your investment and ensures continuous water availability when you need it most. This article will guide you through essential steps for winterizing both above-ground and submersible well pumps, ensuring your system remains intact despite freezing temperatures.

By following these straightforward measures, you can avoid serious complications and maintain peace of mind throughout winter.

Types of Well Pumps and Their Winterization Needs

Above-Ground Well Pumps (Shallow and Jet Pumps)

Above-ground well pumps, including shallow and jet pumps, are particularly vulnerable to freezing temperatures since they are exposed to cold air. The risk of freezing increases significantly during harsh winter months, which can lead to frozen pipes and damaged pumps.

To effectively winterize these systems, insulating the pump and all exposed pipes is crucial. Additionally, draining water from the system will help to eliminate any leftover moisture that could freeze and expand, causing potential damage.

Submersible Well Pumps

In contrast, submersible well pumps are installed deep underground, making them less susceptible to freezing. However, these pumps still require careful winterization procedures, particularly regarding the plumbing connecting the pump to the surface and the components above the ground.

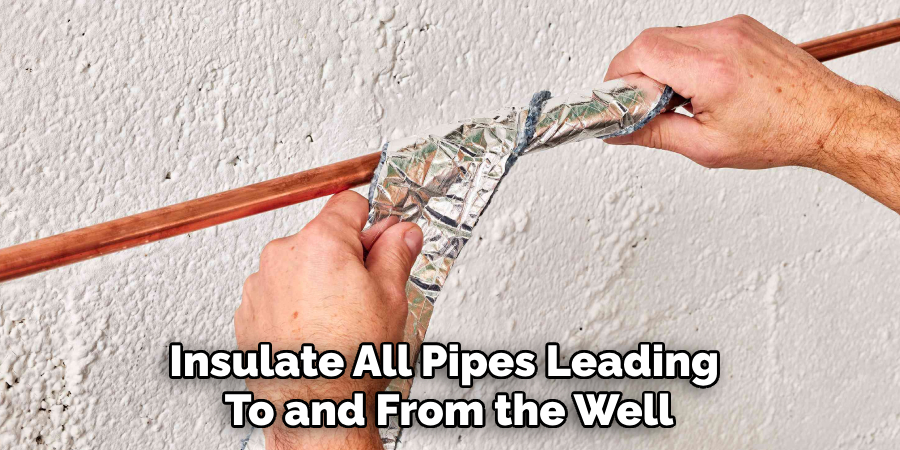

It is essential to insulate all pipes leading to and from the well and the well casing cap to prevent cold air from seeping into the system. Proper winterization ensures that submersible systems function reliably throughout the winter months without risk of freezing.

Preparing for Winterization

Gather Supplies

Before beginning the winterization process, gathering all necessary supplies is essential to ensure a smooth and effective operation. You will need pipe insulation to protect exposed pipes, heat tape to provide additional warmth to critical areas, and electrical tape for securing connections.

Non-toxic antifreeze suitable for RV or marine use is crucial for preventing freezing in the pressure tank. Additionally, have a wrench and pliers on hand for making adjustments and repairs and a bucket for draining water from the system. Having these items ready will streamline the winterization procedures.

Safety Precautions

Prioritizing safety is vital when winterizing your well pump. Ensure you turn off the power supply to the pump before you begin work to avoid any electrical hazards. It’s also advisable to wear gloves to protect your hands from cold temperatures and sharp objects.

Ensure the area around the well is free from debris, allowing for easy access and preventing trip hazards. Following these safety precautions will safeguard your well pump winterization efforts and ensure your personal safety throughout the procedure.

How to Winterize a Well Pump: Winterizing an Above-Ground Well Pump

Step 1: Turn Off the Power and Water Supply

Before beginning the winterization process, turning off the power to the well pump at the circuit breaker is crucial. This prevents any risk of electrocution while you work on the system.

Additionally, the water supply valve must be closed to stop water from entering the pump during winterization. By ensuring both the power and water supply are shut off, you create a safe environment for maintenance and guarantee that no residual water will remain in the pump, which could freeze and lead to significant damage.

Step 2: Drain the Pump and Pipes

Once the power and water supply are turned off, the next step is to drain the pump and associated pipes. Begin by disconnecting the pump from the water supply line to prevent any backward flow. Position a bucket beneath the pump to catch any water as it drains.

Open all the taps connected to the system, which will help relieve pressure and allow any remaining water in the pipes to flow out. Make sure to drain the pressure tank, as lingering water in this area can also freeze, potentially causing the tank to rupture. By thoroughly draining the entire system, you significantly reduce the risk of freezing, which can lead to costly repairs and replacements.

Step 3: Insulate the Pump and Pipes

Insulation is key to protecting your above-ground well pump from freezing temperatures. Start by wrapping the pump and all exposed pipes with pipe insulation, readily available at hardware stores. Focus on areas most susceptible to cold, such as bends and joints.

Additionally, apply heat tape, which provides warmth to critically vulnerable areas prone to freezing. Secure the insulation and heat tape with electrical tape to ensure a tight fit, preventing any gaps through which cold air could penetrate. Proper insulation and the use of heat tape are essential strategies in maintaining a stable temperature around your well pump, ultimately preventing freezing during extreme cold spells and ensuring your system functions reliably throughout the winter months.

Step 4: Cover the Pump

As a final step, place a weather-resistant cover or an insulated box over the pump to protect against the elements. This extra layer of defense is vital in shielding the pump from harsh winter conditions, including freezing temperatures and biting winds, thereby further decreasing the likelihood of damage during the colder months.

How to Winterize a Well Pump: Winterizing a Submersible Well Pump

Step 1: Turn Off the Power and Water Supply

How to Do It: Begin by shutting off the power to the submersible pump at the circuit breaker. Next, close the water supply valve to prevent water from entering the system while winterizing. To ensure the system is depressurized, open a nearby faucet and allow any remaining water to drain completely from the pipes.

Why It’s Important: Turning off the power and closing the water supply is essential for safety during winterization. This step eliminates the risk of electrical hazards while also preventing water from re-entering the system, which could result in freezing and serious damage.

Step 2: Insulate the Pipes and Well Cap

How to Do It: Wrap all exposed pipes leading to and from the well with pipe insulation. Pay special attention to the well cap, applying foam or another insulated material to prevent cold air from entering the system. Ensure that all insulation is tightly secured to avoid any gaps.

Why It’s Important: Proper insulation prevents freezing temperatures from affecting the pipes and well cap. By insulating these components, you help maintain a steady water flow during winter conditions and safeguard your system against potential freezing hazards that could impair functionality.

Step 3: Add Antifreeze to the Pressure Tank

How to Do It: Carefully pour non-toxic antifreeze into the pressure tank to protect it from freezing. Make sure to use antifreeze specifically designed for water systems, ensuring it is safe for drinking water and compliant with relevant health standards.

Why It’s Important: Adding antifreeze to the pressure tank is vital as it prevents the water inside from freezing, which can cause the tank to crack and result in costly repairs. This precaution helps maintain the system’s integrity during cold weather and ensures that it operates efficiently when needed.

Step 4: Check for Leaks and Secure the Area

How to Do It: After completing the previous steps, inspect all connections for leaks and tighten fittings if necessary. Additionally, confirm that the well cap is securely fastened to protect the system from outside debris and moisture.

Why It’s Important: Ensuring a well-sealed system is crucial to reduce the winter damage risk. By checking for leaks and securing the area, you can avoid potential water loss and maintain the stability of the submersible well pump throughout the cold months. This proactive approach guarantees that your system will remain functional and reliable even in harsh winter conditions.

Additional Winterization Tips

Install a Frost-Free Hydrant

How to Do It: Consider installing a frost-free hydrant to provide easier access to water during the winter months without the risk of frozen pipes. These hydrants work by positioning the outlet above the frost line, preventing water from remaining in the exposed sections and freezing.

Installation typically involves digging a trench to connect the hydrant to your water source, ensuring proper drainage away from the well.

Why It’s Important: A frost-free hydrant ensures a reliable winter water supply while protecting your well system from freezing. This convenient solution offers peace of mind, allowing you to access water as needed without concern for pipe breakage or extended thawing times.

Monitor the Well Regularly

How to Do It: Throughout winter, make it a habit to regularly check your well pump and all connected components for any emerging issues. Pay attention to signs of freezing or leaks; swift action can be crucial. Keep an eye on the pressure gauge and observe water flow characteristics.

Why It’s Important: Early detection of potential problems can prevent costly repairs. Routine monitoring allows for prompt adjustments or repairs, ensuring the system remains functional and reducing the likelihood of severe damage from freezing conditions. By being proactive, you can safeguard your well and maintain its efficiency throughout the winter months.

Dealing with a Frozen Well Pump

Signs of a Frozen Pump

Recognizing the signs of a frozen well pump early can help prevent extensive damage. Common indicators include a complete lack of water flow or significantly reduced water pressure when faucets are opened.

Additionally, you may hear unusual noises emanating from the pump, such as rattling or humming, indicating that the pump is struggling to function. Monitoring these signs closely during cold spells can save you from substantial repair costs.

Thawing the Pump

If you suspect that your well pump is frozen, it’s crucial to thaw it safely. Begin by turning off the pump’s power to prevent further damage. Gradually warm the area around the pump using a space heater or heat lamp, ensuring the heat is directed away from electrical components. Avoid applying direct heat to the pump itself, as this can cause cracks or other damage. Monitor the thawing process closely until water flow is restored.

When to Call a Professional

While many homeowners may feel comfortable winterizing their well systems, there comes a time when professional assistance is invaluable. Suppose the well system is complex or situated in an area susceptible to extreme winter conditions.

In that case, it is often wise to hire a professional to address all winterization aspects appropriately. Professionals possess the expertise and tools to identify potential vulnerabilities and implement effective solutions tailored to your system’s needs.

Complex Winterization Needs

It’s recommended to seek professional help for systems with multiple components or those that require advanced knowledge of plumbing and electrical systems. They can assess risks, provide high-quality insulation, and ensure that all system parts are adequately prepared for the cold months ahead.

Dealing with Frozen Systems

When the pump or pipes have frozen, seeking professional support is crucial. Attempting to resolve these issues without adequate knowledge can lead to further damage. Contacting a plumber or well specialist ensures that the situation is handled efficiently and safely, preserving the integrity of your water system.

Conclusion

Winterizing your well pump is a crucial process that ensures both above-ground and submersible systems remain functional during colder months. Key steps include adding non-toxic antifreeze to the pressure tank, checking for leaks and securing the area, installing a frost-free hydrant, and regularly monitoring the system for any signs of trouble.

Proper preparation is essential, as neglecting to winterize can lead to expensive repairs and unexpected interruptions in your water supply. Therefore, learning how to winterize a well pump effectively can save you considerable time and money.

To protect your well system efficiently, plan ahead and initiate the winterization process well before the first freeze. This proactive approach will ensure your water supply remains uninterrupted and your system operates reliably throughout the winter season.